Services

Natural Stone Roller (Granite

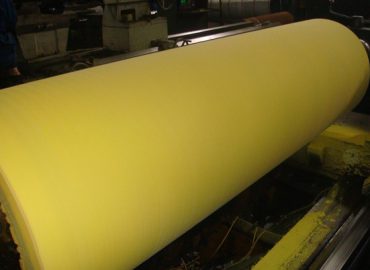

Rubber Press Roller

Imitation Stone Roller

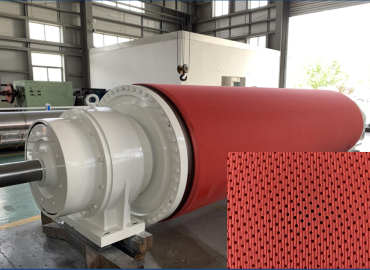

Blind Drilled Press Roll

Vacuum Press Roll

Guide Rolls Series

How We Engineer Your High-Performance Paper Machine Rollers

Consultation & Design

Understanding your specific needs and technical requirements to design custom paper machine rollers for optimal performance.

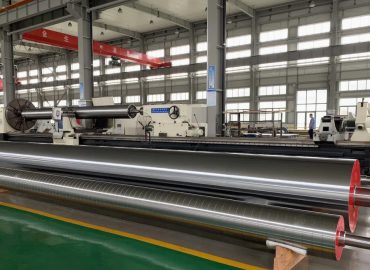

Precision Manufacturing

Utilizing advanced CNC machining and quality materials for the precise fabrication of every roller component.

Quality Control & Testing

Rigorous inspection and testing throughout the manufacturing process to ensure each paper roller meets our highest quality standards.

Delivery & Support

Secure packaging and timely global delivery of your rollers, backed by our dedicated after-sales support and technical assistance.

Our Core Manufacturing & Service Features

Premium Grade Materials

We utilize only high-quality, certified raw materials to ensure the superior strength, wear resistance, and longevity of every paper machine roller.

Rigorous Quality Control

Every roller undergoes comprehensive quality inspections and performance testing before dispatch to ensure it meets the highest industry standards.

Precision Engineering

Our state-of-the-art manufacturing processes and strict adherence to engineering tolerances guarantee perfectly balanced and dimensionally accurate rollers.

Expert Technical Support

Our experienced engineers provide comprehensive technical support, from initial consultation and installation guidance to after-sales service.

Tailored Customization

We offer fully customized roller designs based on your specific paper machine requirements, application needs, and operational goals.

Global Delivery & Logistics

We have established efficient logistics to ensure reliable and timely delivery of our paper machine rollers to clients worldwide.

Your Questions About Our Paper Machine Rollers Answered

Find answers to common inquiries about our roller manufacturing, customization options, quality assurance, and services for the paper industry.

We manufacture a comprehensive range of paper machine rollers, including press rollers, guide rollers (felt, wire, paper), calender rollers (hard & soft nip), stone rollers, rubber-covered rollers, grooved rolls, blind drilled rolls, vacuum rolls, and specialized custom-designed rollers to meet specific application needs within the paper mill.

Absolutely. Customization is a core part of our service. Our engineering team works closely with clients to understand their specific paper machine configurations, operational parameters, and desired outcomes to design and manufacture rollers that are perfectly tailored to their needs, ensuring optimal performance and integration.

We implement stringent quality control throughout the entire roller manufacturing process. This includes rigorous inspection of raw materials, precision monitoring during machining and fabrication, balancing tests, NDT (Non-Destructive Testing) where applicable, and final dimensional and performance checks to ensure every roller meets international quality standards and our clients’ specifications.

Lead times for our paper machine rollers can vary depending on the complexity of the design, material availability, and current production schedules. We strive to provide accurate lead time estimates upon order confirmation and work diligently to meet agreed delivery timelines. For standard rollers, lead times are generally shorter than for highly customized or large-scale orders.

Need High-Performance Paper Machine Rollers?

Copyright ©2025 Hs Roller | All rights reserved.