Choosing the Right Paper Machine Rolls Manufacturer

In the complex world of paper production, every component plays a vital role in ensuring efficiency, quality, and profitability. Among these critical elements, paper machine rolls stand out. These workhorses are subjected to immense pressure, high temperatures, and continuous friction, making their design, material, and manufacturing quality paramount. Selecting the right paper machine rolls manufacturer isn’t merely a procurement decision; it’s a strategic partnership that directly impacts your mill’s performance. The right manufacturer provides not just components, but engineered solutions that contribute to higher speeds, fewer breaks, better paper finish, and reduced downtime. Conversely, choosing poorly can lead to premature wear, costly repairs, and significant production losses. Have you ever considered the sheer precision required for a roll rotating at thousands of revolutions per minute under tons of load? It’s a testament to advanced engineering and manufacturing prowess.

The Heart of Paper Production: Understanding Paper Machine Rolls

Paper machine rolls are far from simple cylinders. They are sophisticated, engineered components, each designed for a specific function within the various sections of a paper machine – from the forming section to the press, dryer, sizing, calender, and reel sections. Each type of roll, whether it’s a couch roll, press roll, dryer cylinder, or calender roll, faces unique operational challenges and requires specialized design considerations. For instance, press rolls must withstand tremendous pressure while efficiently dewatering the paper web, often incorporating complex internal structures or external coatings. Dryer cylinders, on the other hand, handle high temperatures and require materials that ensure efficient heat transfer while resisting deformation. The precise geometry, surface properties, balance, and internal cooling or heating systems are all critical factors that influence their performance and lifespan. Frankly speaking, the effectiveness of your entire paper machine hinges significantly on the reliability and performance of its rolls.

Precision Engineering for Optimal Roll Performance

The demands placed upon paper machine rolls necessitate extreme precision in their engineering and manufacturing. Tolerances measured in microns are commonplace, particularly for surface profiles and concentricity. The materials used must be carefully selected to endure harsh operating environments, resisting corrosion, abrasion, and fatigue. Advanced coatings and coverings, ranging from rubber and polymer to ceramic and metallic options, are applied to provide specific surface properties tailored to the roll’s function and the type of paper being produced. Achieving the perfect balance is also crucial; unbalanced rolls can cause vibration, leading to poor paper quality, accelerated bearing wear, and even structural damage to the machine. This level of technical requirement means that not just any machine shop can produce high-quality paper machine rolls. It requires a manufacturer with deep expertise, specialized equipment, and a profound understanding of papermaking processes. In my experience, this is where the value of a dedicated paper machine rolls manufacturer truly shines.

What Sets Apart a Leading Paper Machine Rolls Manufacturer?

Identifying a truly leading paper machine rolls manufacturer involves looking beyond just their manufacturing capabilities. It’s about finding a partner committed to innovation, quality, and customer service. A top manufacturer invests heavily in research and development, constantly exploring new materials, coatings, and design methodologies to improve roll performance and lifespan. They employ stringent quality control procedures at every stage of production, from raw material inspection to final dynamic balancing and dimensional checks. Their expertise extends to understanding the specific needs of different paper grades and machine types, allowing them to recommend or design the optimal roll solution. Furthermore, a strong commitment to customer support, including technical assistance, installation guidance, and troubleshooting, is a hallmark of a reputable manufacturer. They don’t just sell you a product; they partner with you to ensure its success within your operation. It’s worth noting that this partnership approach can significantly streamline operations and reduce total cost of ownership over time.

Material Science and Coating Expertise in Roll Manufacturing

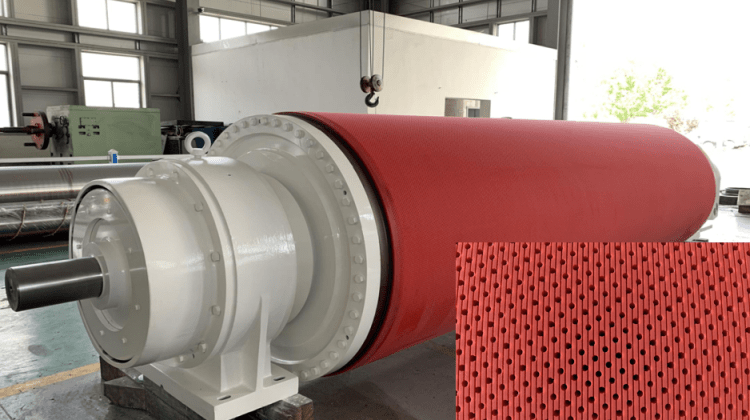

The performance of a paper machine roll is inherently linked to the materials used in its construction and the surface treatment it receives. A skilled paper machine rolls manufacturer possesses extensive knowledge in material science, understanding the properties of different steels, cast irons, composites, and other core materials suitable for varying loads and conditions. They also have expertise in applying a wide range of roll coverings and coatings – from traditional rubber and polyurethane to advanced ceramics, carbides, and specialized polymer blends. These coatings are not just for protection; they are engineered to provide specific surface characteristics such as hardness, friction coefficient, release properties, and resistance to wear or chemical attack. For example, a calender roll might require an extremely hard, smooth surface for glossing, while a press roll covering needs specific elastic properties for optimal dewatering. The ability to recommend and expertly apply the right material and coating for a specific application is a key differentiator for a manufacturer, enabling them to produce truly custom paper machine rolls tailored to your mill’s unique needs.

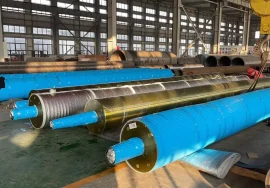

The Manufacturing Process: From Raw Material to Finished Roll

The journey of a paper machine roll from raw material to a precision-engineered component is a complex undertaking involving multiple stages, each requiring specialized machinery and skilled craftsmanship. It typically begins with the selection and preparation of the core material, often involving casting or forging large steel or iron blanks. These blanks are then meticulously machined on large-scale lathes to achieve the basic dimensions and geometry. Grinding follows, using high-precision grinders to achieve the required surface finish and precise crown profile – the slight curvature essential for maintaining uniform nip pressure across the web width. Balancing, both static and dynamic, is a crucial step to prevent vibrations during high-speed operation. Finally, the application of coverings or coatings and rigorous final inspection complete the process. Each step is critical, and errors at any point can compromise the roll’s performance and lifespan. This detailed, multi-stage process underscores the necessity of partnering with a manufacturer equipped with the right technology and expertise for paper mill roll manufacturing.

Quality Control and Inspection Standards for Reliability

For a paper machine roll manufacturer, quality control isn’t an afterthought; it’s an integral part of the process, ensuring that every roll meets the stringent standards required for reliable operation in a paper mill. Reputable manufacturers implement comprehensive inspection protocols throughout the production cycle. This includes rigorous testing of raw materials, in-process checks during machining and grinding to verify dimensions and tolerances, and non-destructive testing (NDT) methods like ultrasonic or magnetic particle inspection to detect any internal flaws in the metal. Surface finish measurements, profile checks, and dynamic balancing tests are performed on the completed roll to guarantee its performance characteristics. Documentation of these tests provides traceability and assures the customer of the roll’s quality. A manufacturer’s commitment to these high standards is a direct reflection of their dedication to producing rolls that minimize risk and maximize uptime for paper producers. Why settle for less when production reliability is on the line?

Beyond Manufacturing: Comprehensive Support and Service

A truly valuable partner in the paper industry doesn’t just manufacture rolls; they offer comprehensive support and service throughout the roll’s lifecycle. This can include technical consultation during the design phase to optimize roll specifications for your specific application, assistance with installation to ensure proper seating and alignment, and expert advice on operation and maintenance to maximize roll life and performance. Furthermore, services like inspection, repair, and refurbishment are often available, offering cost-effective alternatives to outright replacement for worn or damaged rolls. Many manufacturers also provide specialized services such as grinding and balancing on-site or at their facility. This holistic approach means that the manufacturer is invested in your long-term success, providing solutions not just when you need a new roll, but throughout the operational life of their product. This kind of ongoing partnership is invaluable for optimizing paper mill roll maintenance and minimizing unexpected downtime.

Addressing Common Challenges with the Right Manufacturer Partner

Paper mills frequently face challenges related to their rolls, including premature wear, surface damage (like barring or cracking), vibration issues, and unexpected failures leading to costly downtime. A proactive paper machine rolls manufacturer can help address these problems. By analyzing the root causes of past roll failures or performance issues, they can recommend design modifications, material changes, or alternative coatings that are better suited to the operating conditions. Their expertise in dynamic analysis can help diagnose and resolve vibration problems. Moreover, having a reliable partner for timely repair and refurbishment services is crucial for quickly getting damaged rolls back into service, reducing the need for extensive spare parts inventory and minimizing production interruptions. Partnering with a manufacturer who understands these common pain points and has the technical capability to provide effective solutions is key to improving overall mill efficiency and reliability.

Choosing Your Partner: Key Questions to Ask

When the time comes to select a paper machine rolls manufacturer, knowing what questions to ask is paramount. You need a partner you can trust. Start by inquiring about their experience – how long have they been manufacturing rolls for paper machines? What is their track record with mills similar to yours? Ask about their manufacturing capabilities: Do they have the necessary large-scale machinery for your roll sizes? What are their precision tolerances? Request details on their quality control process and inspection standards. How do they ensure balance and surface accuracy? Don’t forget to discuss their R&D efforts and their ability to provide innovative solutions or custom paper machine rolls. Finally, assess their service and support structure – what kind of technical assistance do they offer? Do they provide repair or refurbishment services? Asking these specific questions will help you evaluate their expertise, reliability, and suitability as a long-term partner for selecting the right paper machine rolls and ensuring their optimal performance.

Ultimately, the performance and longevity of your paper machine rolls are critical determinants of your paper mill’s productivity and the quality of the paper you produce. Choosing a paper machine rolls manufacturer requires careful consideration, looking beyond initial cost to assess their technical expertise, manufacturing quality, commitment to innovation, and level of customer support. A truly excellent manufacturer acts as a partner, providing not just precision-engineered components but also the knowledge and services needed to optimize your roll performance throughout its operational life. By prioritizing experience, technology, quality control, and comprehensive service, you can secure a partnership that contributes significantly to your mill’s efficiency, reliability, and competitive edge in the market. Make an informed decision, and invest in quality that pays dividends.

For more detailed information, please visit our official website: paper machine rolls manufacturer