Your Trusted Paper Mill Rolls Manufacturer Partner

In the intricate world of paper production, where precision, speed, and reliability are paramount, the quality of your equipment is non-negotiable. At the heart of this machinery lie the rolls – components that are absolutely fundamental to forming, pressing, and finishing paper sheets. These rolls endure incredible stresses, high temperatures, and corrosive environments, making their design and manufacturing a highly specialized field. Frankly speaking, the performance and longevity of your entire paper machine line often hinge on the quality of its rolls. This is precisely why selecting a knowledgeable and experienced paper mill rolls manufacturer isn’t just a procurement decision; it’s a strategic investment in your operation’s future. A leading manufacturer doesn’t just supply parts; they provide engineered solutions tailored to the unique demands of your specific mill, ensuring consistent production quality and minimizing costly downtime. Think about the sheer volume of material passing over these rolls daily; any imperfection or failure can have immediate and significant consequences for output and product quality. Partnering with the right expert is the first step towards optimizing your paper machine’s potential.

Understanding the Critical Role of Different Paper Mill Rolls

Paper machines utilize a variety of rolls, each serving a distinct, vital function in the transformation of pulp slurry into finished paper. The forming section relies on forming rolls, including breast rolls and couch rolls, which are crucial for draining water from the pulp and initiating the sheet formation process. Moving into the press section, press rolls dewater the sheet further through intense pressure, consolidating the fibers. Then, in the dryer section, dryer rolls transport the sheet through heated cylinders to remove remaining moisture. Finally, calendar rolls smooth and finish the paper surface. Each type of roll faces unique operational challenges – be it the abrasive nature of the pulp, the high pressures in the press section, or the thermal demands of the dryer section. A proficient paper mill rolls manufacturer possesses the deep understanding of these different roles and stresses required to engineer rolls capable of withstanding these conditions consistently. Have you ever wondered about the complex internal designs, cooling systems, or specialized coatings required for each roll type to perform flawlessly under duress?

Engineering Excellence in Couch and Press Rolls

Let’s delve a little deeper into two particularly critical types: couch rolls and press rolls. Couch rolls, typically found at the end of the forming section, use vacuum or centrifugal force to remove a significant amount of water, consolidating the fragile web of paper. The design of the vacuum system and the integrity of the roll shell are paramount here to prevent crushing the delicate sheet. Press rolls, on the other hand, operate under massive linear pressures, sometimes thousands of pounds per lineal inch. This pressure removes water mechanically, dramatically increasing the sheet’s dryness before it enters the energy-intensive dryer section. The materials used for press roll shells and coverings must withstand extreme mechanical loads and potential chemical attack from process water and additives. The core value proposition of a skilled paper mill rolls manufacturer lies in their ability to design and produce these rolls with the necessary structural integrity, surface hardness, and dimensional accuracy to perform reliably under these severe conditions, contributing directly to increased dryness and reduced energy consumption.

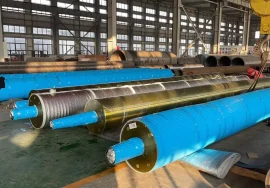

Materials and Manufacturing: The Foundation of High-Performance Mill Rolls

The performance of paper mill rolls is fundamentally linked to the materials selected and the precision of the manufacturing process. Rolls are typically constructed from high-quality cast iron, steel, or composite materials, chosen for their strength, stiffness, and durability. The surface of the roll is often covered with specialized materials like rubber, polyurethane, or advanced ceramic coatings, each offering specific advantages in terms of grip, dewatering, wear resistance, and chemical inertness. The manufacturing process itself is an intricate blend of traditional craftsmanship and cutting-edge technology. It involves initial casting or forging, followed by extensive machining to achieve incredibly tight tolerances for concentricity, straightness, and surface finish. Precision grinding and balancing are critical steps to ensure smooth, vibration-free operation at high speeds, which is essential for consistent paper quality and machine longevity. Many experts agree that the investment in superior materials and rigorous manufacturing processes by a leading paper mill rolls manufacturer pays dividends in terms of extended roll life and reduced maintenance needs.

The Art and Science of Precision Machining and Balancing

Achieving the required precision for paper mill rolls is a true testament to engineering skill. Rolls can be several meters long and weigh many tons, yet they must be machined to tolerances often measured in microns. Think about the challenge of ensuring a roll weighing 50 tons remains perfectly cylindrical and straight along its entire length, or that its surface finish is uniform down to the microscopic level. This precision is not just about static dimensions; it’s about dynamic performance. Rolls spinning at high speeds can generate significant vibrations if not perfectly balanced. Imbalance leads to uneven wear, poor paper quality, and can even damage the paper machine structure over time. State-of-the-art balancing equipment is essential to ensure that rolls run smoothly at operational speeds. The ability of a manufacturer to consistently deliver rolls with this level of precision in both machining and balancing is a key differentiator, directly impacting the stability and efficiency of the paper machine. It’s worth noting that achieving this requires not only advanced machinery but also highly skilled technicians with years of experience.

Addressing Common Challenges with Expertly Crafted Rolls

Paper mill environments are notoriously harsh, presenting numerous challenges for machinery. Wear from abrasive fibers and fillers, corrosion from process chemicals and water, fatigue cracking from cyclic stresses, and build-up of sticky substances are all common issues that can degrade roll performance and lifespan. A proactive paper mill rolls manufacturer anticipates these challenges and engineers solutions into their products. This might involve selecting specific alloys or composite materials for increased corrosion resistance, applying advanced wear-resistant coatings, designing internal structures to dissipate stress concentrations, or incorporating features that minimize stock build-up. Frankly speaking, merely replacing worn rolls isn’t a long-term solution if the underlying material or design isn’t optimized for the specific conditions of your mill. The expertise in diagnosing these issues and providing tailored roll designs or refurbishment strategies is a significant value provided by a top manufacturer, helping mills improve reliability and reduce operational headaches caused by roll-related problems like premature wear or surface pitting.

Customization: Tailoring Rolls to Your Mill’s Specific Needs

No two paper mills are exactly alike. Variations in machine design, paper grades produced, furnish composition, operating speeds, and environmental conditions all impact the specific requirements for paper mill rolls. This is where the ability to provide custom paper machine rolls becomes incredibly valuable. A leading manufacturer works closely with mill engineers to understand their unique challenges and performance goals. This collaborative approach allows for the design and production of rolls optimized for specific positions on specific machines, considering factors like desired surface properties, load capacities, operating temperatures, and resistance to particular chemical environments. It’s not just about size and shape; it’s about engineering the roll to excel in its precise role within your distinct process. For example, a mill producing high-strength board might require rolls with different surface characteristics or internal reinforcement compared to a mill producing fine printing paper. The flexibility and engineering depth to offer tailored solutions are hallmarks of an excellent paper mill rolls manufacturer, ensuring that the rolls integrate seamlessly and deliver peak performance.

The Importance of Maintenance and Paper Roll Refurbishing Services

Even the highest quality paper mill rolls require regular maintenance and, eventually, refurbishment to maintain peak performance and extend their operational life. Rolls are subjected to constant wear and tear, which can lead to changes in surface profile, hardness, and balance. Proactive maintenance, including regular inspections, cleaning, and surface conditioning, is essential. However, when wear becomes significant, or damage occurs, refurbishing is often a cost-effective alternative to complete replacement. Paper roll refurbishing services provided by an experienced manufacturer typically involve stripping the old cover or coating, inspecting the core for damage, repairing any defects, re-machining or grinding the surface, and applying a new cover or coating. The process is complex and requires the same level of precision and expertise as manufacturing new rolls. Entrusting refurbishment to the original manufacturer or a specialist with deep knowledge of roll engineering ensures that the repaired roll meets original specifications and will perform reliably. Why invest in high-performance mill rolls if you can’t maintain or refurbish them effectively?

Choosing the Right Partner: What to Look for in a Manufacturer

Selecting the optimal paper mill rolls manufacturer is a decision that impacts your mill’s efficiency, reliability, and profitability for years to come. What criteria should you consider? Experience is paramount – look for a manufacturer with a proven track record specifically in paper mill rolls, demonstrating an understanding of the unique demands of the industry. Engineering capability is another key factor; can they offer customized solutions and technical support? Manufacturing precision and quality control are non-negotiable; inquire about their processes and tolerances. Material expertise is also vital; do they have access to and knowledge of the latest materials and coatings? Furthermore, consider their service capabilities, including field support, inspection services, and refurbishment options. A manufacturer that acts as a true partner, offering expertise from design to maintenance, provides far more value than one simply selling components. Building a long-term relationship with a trusted supplier ensures you have access to expertise and support when you need it most.

Maximizing Mill Performance with High-Performance Mill Rolls

The ultimate goal for any paper mill is to maximize throughput, maintain consistent quality, and minimize operational costs. The quality and performance of paper mill rolls directly contribute to achieving these objectives. High-performance mill rolls, designed and manufactured by experts, offer numerous benefits. They can improve dewatering efficiency, leading to energy savings in the dryer section. Their precise dimensions and surface finishes contribute to better paper quality, reducing rejects. Their durability and resistance to wear and corrosion minimize unexpected breakdowns and reduce the frequency of maintenance or replacement. This translates into increased uptime, higher productivity, and lower overall maintenance expenditures. Investing in superior rolls from a reputable manufacturer is not just a cost; it’s an enabler for higher profitability and greater competitive advantage in the marketplace. Consider the cumulative impact of small efficiency gains or reduction in downtime over a year – it can be substantial. Partnering with the right manufacturer helps unlock this potential.

Looking Ahead: Innovation and the Future of Paper Roll Manufacturing

The paper industry is constantly evolving, driven by demands for higher speeds, new paper grades, and increased sustainability. The role of the paper mill rolls manufacturer is also evolving, with a continuous focus on innovation. Research and development are exploring new materials, advanced coatings, and innovative roll designs to meet future challenges. This includes lightweight composite materials for reduced energy consumption, smart rolls equipped with sensors for real-time monitoring of temperature, pressure, and vibration, and coatings that offer unprecedented resistance to wear and build-up. Manufacturers are also leveraging advanced digital technologies, such as simulation and data analytics, to optimize roll performance and predict maintenance needs. Staying at the forefront of these technological advancements allows manufacturers to provide mills with rolls that are not only reliable today but also equipped to handle the demands of tomorrow’s paper production environments. This forward-thinking approach ensures that their clients remain competitive.

Conclusion: Partnering for Success in Paper Production

In summary, the role of the paper mill rolls manufacturer is absolutely critical to the success and efficiency of any paper production operation. From the initial forming of the sheet through pressing, drying, and finishing, the quality and precision of the rolls directly impact paper quality, production speed, energy consumption, and operational reliability. Choosing a manufacturer with deep expertise, advanced manufacturing capabilities, and a commitment to service and innovation is a decision that will yield long-term benefits. Look for a partner who understands your specific challenges and can provide tailored solutions, from designing custom paper machine rolls to offering comprehensive paper roll refurbishing services. Investing in high-performance mill rolls from a trusted supplier minimizes downtime, improves product quality, and ultimately contributes to a more profitable and sustainable operation. Ready to explore how expertly crafted rolls can enhance your mill’s performance? Taking the next step involves connecting with a manufacturer capable of meeting your unique needs and challenges.

For more detailed information, please visit our official website: paper mill rolls manufacturer