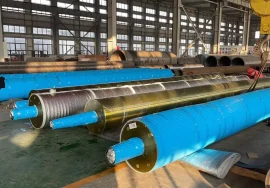

Large Diameter Stainless Steel Blind Press Roll for Recycled Paper Machinery

When it comes to recycled paper production, the quality of machinery components directly impacts efficiency and output. Among these, the large diameter stainless steel blind press roll stands out as a critical element. Designed to withstand high pressure and continuous operation, these rolls play a pivotal role in ensuring smooth paper processing while maintaining structural integrity. But what makes them indispensable in modern recycled paper machinery?

Understanding the Role of Blind Press Rolls in Paper Recycling

Blind press rolls are essential in the dewatering and pressing stages of paper production. Unlike traditional rolls, they feature a smooth, perforated surface that allows water to escape while maintaining uniform pressure distribution. In recycled paper machinery, where fibers are often shorter and more fragile, the precision of these rolls becomes even more crucial. A large diameter design enhances stability, reducing vibration and ensuring consistent performance under heavy loads.

Why Stainless Steel Matters

Stainless steel isn’t just a material choice—it’s a necessity. The corrosive nature of recycled paper pulp, combined with high moisture levels, demands a material that resists rust and wear. Stainless steel blind press rolls offer superior durability, reducing maintenance downtime and extending the lifespan of the machinery. Additionally, their smooth surface minimizes fiber damage, preserving the quality of the recycled paper.

Key Advantages of Large Diameter Designs

The diameter of a press roll isn’t arbitrary. Larger diameters provide several operational benefits:

- Enhanced load-bearing capacity – Distributes pressure more evenly, preventing deformation under heavy use.

- Improved dewatering efficiency – The increased surface area allows for better water extraction, speeding up production.

- Reduced maintenance needs – Fewer replacements and adjustments mean lower operational costs.

In high-volume recycled paper facilities, these advantages translate to significant cost savings and higher output consistency.

Applications in Modern Recycled Paper Machinery

From small-scale recycling plants to large industrial setups, stainless steel blind press rolls are versatile. They’re commonly used in:

- Press sections of paper machines

- Dewatering systems

- Pulp refining stages

Their ability to handle varying pulp consistencies makes them ideal for recycled paper production, where material properties can fluctuate.

Common Challenges and Solutions

Even the best equipment faces challenges. For instance, uneven wear can occur if the roll isn’t properly aligned or maintained. Regular inspections and balancing adjustments are key. Additionally, selecting the right surface finish—whether polished or coated—can further enhance performance based on specific operational needs.

Future Trends in Press Roll Technology

As recycled paper production grows, so does the demand for more advanced press roll designs. Innovations like composite materials and smart monitoring systems are emerging, but stainless steel remains a trusted choice for its reliability. The focus is now shifting toward optimizing diameter-to-length ratios and integrating automation for real-time performance tracking.

Have you ever wondered how a single component can make such a difference in paper quality? The answer lies in the precision engineering of these rolls. By investing in high-quality stainless steel blind press rolls, manufacturers can achieve smoother operations, fewer breakdowns, and ultimately, a more sustainable production process.

For more detailed information, please visit our official website: Large Diameter Stainless Steel Blind Press Roll for Recycled Paper Machinery