Durable Cast Iron Guide Roller for Toilet Paper Machines (Spare Part): Key Insights

In the demanding world of modern paper manufacturing, especially within high-speed toilet paper production lines, every component plays a critical role in maintaining efficiency, quality, and uptime. Among these vital elements, guide rollers stand out as unsung heroes, constantly working under significant stress to control the web’s path through various stages of the machine. Their reliability is paramount. When these rollers begin to show signs of wear, or worse, fail unexpectedly, the entire production can grind to a halt, leading to costly downtime and potential material waste. This underscores the absolute necessity of having readily available and exceptionally reliable spare parts. Specifically, a high-quality Durable Cast Iron Guide Roller for Toilet Paper Machines (Spare Part) is not just a replacement part; it’s an investment in operational continuity and long-term machine health. Understanding the intricacies of these rollers, why cast iron is often the material of choice, and what factors contribute to their longevity is essential for anyone involved in managing, maintaining, or procuring components for this specialized machinery. To be honest, overlooking the quality of such a seemingly simple part can have disproportionately large negative impacts on your bottom line, making the selection process far more important than it might initially appear. Have you ever truly calculated the cost of unscheduled downtime caused by component failure?

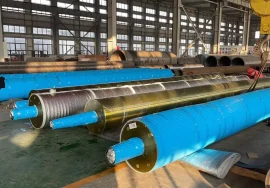

Understanding the Critical Function of Guide Rollers in Tissue Production

Guide rollers in a toilet paper machine perform a fundamental, yet incredibly challenging, task: accurately guiding the paper web from one section of the machine to the next. They are strategically positioned throughout the line, from the wet end or forming section, through pressing, drying, and onto the reel. Their primary function is to maintain proper web tension, control web position, and ensure smooth, wrinkle-free travel. Considering the speeds at which modern tissue machines operate – often thousands of meters per minute – even a slight misalignment or surface imperfection on a guide roller can lead to web breaks, quality defects, or excessive wear on other, more expensive machine parts. These rollers often operate in harsh environments characterized by high temperatures, significant humidity, residual chemicals, and the constant presence of paper dust and fibers. The cumulative effect of these conditions puts immense stress on the roller’s material and bearings. Frankly speaking, the precision required from these components is remarkable when you consider the scale and speed of the operation. They are not just spinning cylinders; they are critical control points that directly influence the quality and efficiency of the final product. The continuous loading, vibration, and environmental exposure necessitate a material that can withstand such prolonged, rigorous service without deformation or excessive wear, highlighting the demand for a truly robust solution in paper making equipment.

Why Cast Iron Stands Out for Toilet Paper Machine Rollers

Given the challenging operational environment, the material selection for guide rollers is paramount. Cast iron has historically been, and continues to be, a preferred material for many heavy-duty applications in industrial machinery, including paper manufacturing. Its suitability for guide rollers in toilet paper machines stems from a combination of desirable properties. First and foremost, cast iron offers excellent compressive strength and rigidity, allowing it to maintain its shape and integrity under the significant loads and tensions inherent in paper web guiding. Secondly, it possesses good damping characteristics, which helps to absorb vibrations generated during high-speed operation, contributing to smoother web travel and reduced noise. Furthermore, certain grades of cast iron exhibit good wear resistance, particularly when properly manufactured and finished. Importantly for large components, cast iron is relatively cost-effective compared to other high-strength materials and is readily available. Its machinability also allows for the creation of precise surface finishes and dimensional accuracy required for optimal roller performance. While other materials like steel or composites are used in specific applications, cast iron provides a proven, reliable, and economically viable foundation for a durable guide roller. It’s worth noting that not all cast iron is created equal; the specific grade and quality of the casting process significantly influence the final roller’s performance and lifespan.

Factors Defining a Durable Cast Iron Guide Roller

What exactly makes a cast iron guide roller truly durable in the context of a high-speed toilet paper machine? It’s not just about using cast iron; it’s about the entire lifecycle of the component, starting from its design and manufacturing. A truly durable roller begins with the selection of the appropriate grade of cast iron, ensuring it meets stringent metallurgical standards for strength, hardness, and grain structure. The casting process itself must be meticulously controlled to avoid defects like porosity or inclusions that could become stress points. Subsequent machining is equally critical, requiring high precision to achieve the exact dimensions, concentricity, and surface finish demanded by the application. Often, durable rollers undergo specific surface treatments, such as specialized coatings or surface hardening, to enhance wear resistance, prevent corrosion, or improve release properties, especially if the roller is exposed to moisture or sticky substances. The design of the roller, including wall thickness, ribbing for structural integrity, and the integration of bearing housings, also plays a crucial role in distributing stress and minimizing deflection under load. Finally, the quality of the bearings and seals used is fundamental to the roller’s lifespan, as bearing failure is a common cause of roller malfunction. A truly durable cast iron guide roller for toilet paper machines (spare part) is the result of combining high-quality materials with expert engineering and manufacturing processes, ensuring it can withstand the relentless demands of continuous operation for an extended period, thus serving as a reliable toilet paper machine roller replacement option when the time comes.

Specific Challenges Faced by Rollers in Tissue Environments

Tissue paper production lines present a unique set of challenges that guide rollers must constantly overcome. The speed of operation, as previously mentioned, subjects rollers to significant dynamic loads and vibrations. Unlike some other paper grades, tissue web is relatively delicate, meaning rollers must provide precise control without damaging the sheet, requiring specific surface characteristics. The environment within the machine is often hot and humid, which can accelerate corrosion if the material or surface treatment is not resistant. Furthermore, the constant presence of paper fibers and additives in the air can lead to build-up on roller surfaces, potentially affecting web quality or causing imbalances that lead to vibration and bearing wear. Some sections, like those near the Yankee dryer, experience extreme heat. Other sections might involve chemical exposure from additives or coatings. Rollers in the press section, if applicable, face immense pressure. All these factors combine to create a highly abrasive and corrosive environment that relentlessly attacks mechanical components. Therefore, a guide roller designed for this specific application must possess inherent resistance to these conditions, or be treated to mitigate their effects. Ignoring these specific environmental factors when selecting a spare part is a common mistake that can lead to premature failure and repeated downtime, underscoring the need for components explicitly engineered for these demanding conditions.

Identifying Signs of Wear and the Consequences of Roller Failure

Recognizing the early signs of wear in a cast iron guide roller is crucial for proactive maintenance and preventing catastrophic failures. Visual inspection can reveal surface irregularities such as pitting, scoring, excessive wear patterns, or corrosion. Listen for unusual noises emanating from the roller or its bearings, which could indicate bearing deterioration or imbalance. Feel for excessive heat from the bearing housings during operation. Monitor vibration levels; increased vibration is a strong indicator of imbalance or bearing issues. Observe the paper web itself – signs like wrinkles, edge tears, or inconsistent tension can often be traced back to problems with guide rollers. A change in the roller’s ability to maintain the web’s position accurately is another red flag. The consequences of ignoring these signs can be severe and costly. A failing roller can cause repeated web breaks, leading to significant production losses and waste. Imbalance can damage adjacent machine components, including bearings, shafts, and even structural elements, leading to more extensive and expensive repairs. In severe cases, a complete roller seizure can cause significant machine damage and prolonged, unscheduled downtime. Frankly speaking, the cost of a new Durable Cast Iron Guide Roller for Toilet Paper Machines (Spare Part) is invariably a fraction of the cost of the production losses and repair expenses incurred by allowing a worn roller to fail during operation. Proactive replacement based on condition monitoring is always the more economical approach in the long run.

Best Practices for Extending Guide Roller Lifespan

While choosing a durable cast iron guide roller is the starting point, proper maintenance practices are essential for maximizing its operational lifespan and ensuring continued reliability. Regular inspection is paramount. Develop a detailed inspection schedule that includes checking for surface condition, bearing health (listening, temperature checks, vibration analysis), lubrication levels, and alignment. Ensure that lubrication practices for the bearings are strictly followed, using the correct type and amount of lubricant at the recommended intervals. Preventing contamination of the bearings by paper dust or moisture is vital; effective sealing is critical, but ensuring the seals are intact and functional requires regular checks. Keep roller surfaces clean; preventing build-up reduces the risk of imbalance and surface damage. Address any signs of wear or damage promptly; minor issues like slight surface imperfections can escalate quickly under operational stress. Correct any detected alignment issues immediately, as misalignment puts undue stress on the roller and its bearings. Implementing a robust condition monitoring program that includes vibration analysis and thermography can provide early warnings of impending bearing or balance issues, allowing for planned maintenance rather than reactive repairs. By adhering to these best practices, you can significantly extend the service life of your cast iron guide rollers, reducing the frequency of replacements and minimizing unexpected downtime, thereby protecting your investment in high-quality components.

The Critical Importance of Sourcing High-Quality Spare Parts

When a guide roller reaches the end of its service life, or if proactive replacement is scheduled based on condition, the importance of sourcing a high-quality spare part cannot be overstated. While lower-cost alternatives might seem appealing in the short term, they often lack the material integrity, precision manufacturing, and durability engineering required for the demanding tissue machine environment. An inferior spare part can fail prematurely, leading to repeat replacements, increased maintenance costs, and recurring production interruptions. It might not have the correct dimensional tolerances, leading to installation difficulties or improper function. The cast iron grade might be unsuitable, lacking the necessary strength or wear resistance. Surface treatments might be inadequate, offering poor protection against wear or corrosion. Bearing housings might be inaccurately machined, compromising bearing life. Essentially, choosing a cheap, low-quality spare part is a false economy. A high-quality Durable Cast Iron Guide Roller for Toilet Paper Machines (Spare Part), manufactured to stringent standards by a reputable supplier, is designed to perform reliably under pressure and contribute positively to machine uptime and product quality. It integrates seamlessly into your machine and delivers consistent performance over a predictable lifespan, reducing the total cost of ownership significantly compared to using unreliable components.

Choosing the Right Partner for Your Cast Iron Roller Needs

Selecting a supplier for critical spare parts like cast iron guide rollers requires careful consideration. You need a partner who understands the specific requirements of paper machinery components and has the expertise to manufacture parts that meet or exceed OEM standards. Look for suppliers with a proven track record in producing durable, high-precision cast iron components for demanding industrial applications. Enquire about their manufacturing processes, quality control measures, and the grades of cast iron they utilize. Can they provide documentation regarding material composition and testing? Do they offer surface treatment options tailored to the specific environment of your toilet paper machine? A good supplier should be able to work with you to ensure the replacement roller is dimensionally accurate, properly balanced, and equipped with appropriate bearings and sealing arrangements for your specific machine model and position. They should also be able to offer technical support and advice regarding installation and maintenance. Partnering with a supplier who specializes in paper machine components ensures you receive a Durable Cast Iron Guide Roller for Toilet Paper Machines (Spare Part) that is not only a physical replacement but a performance match for your existing high-speed operations. This partnership is key to minimizing risk and maximizing the return on your investment in spare parts.

The Measurable Benefits of High-Performance Guide Rollers

Investing in high-performance, durable cast iron guide rollers delivers tangible benefits that directly impact the profitability and efficiency of your toilet paper production line. The most immediate benefit is increased uptime. Reliable rollers mean fewer unexpected stops due to component failure, allowing your machine to run continuously and produce more. Reduced web breaks translate directly into less wasted raw material and finished product, improving yield. Consistent, accurate web guiding ensures higher product quality, reducing the amount of off-spec material. Durable rollers require less frequent replacement, lowering maintenance costs associated with purchasing new parts and the labor involved in changing them out. Furthermore, rollers that maintain proper balance and alignment reduce wear and tear on other machine components, potentially extending the lifespan of bearings, shafts, and even the machine’s structure. This cascading effect of reliability contributes to lower overall operating costs and a more predictable production schedule. Interestingly enough, while a single guide roller might seem like a minor part compared to the entire paper machine, its impact on efficiency and profitability is substantial. Choosing a durable cast iron guide roller for toilet paper machines (spare part) is a strategic decision that supports sustained peak performance, ensuring your production line operates smoothly and profitably for years to come.

In conclusion, the seemingly simple guide roller is a cornerstone of reliable operation in high-speed toilet paper machines. The challenges of speed, heat, humidity, and abrasive materials demand a component built for extreme durability. Cast iron, with its strength, rigidity, and damping properties, offers an excellent foundation, but true durability comes from meticulous manufacturing, material quality, and appropriate surface treatments. Recognizing the signs of wear and implementing proactive maintenance are vital steps in maximizing roller lifespan and preventing costly failures. Most importantly, when replacement is necessary, selecting a high-quality Durable Cast Iron Guide Roller for Toilet Paper Machines (Spare Part) from a reputable supplier is not just a transaction; it’s a critical investment in maintaining machine uptime, ensuring product quality, and reducing long-term operating costs. Don’t underestimate the impact of reliable spare parts on your production line’s overall performance. If you are experiencing issues with guide roller lifespan or performance, or simply want to ensure you have the best possible spares on hand, take the next step in securing the reliability of your toilet paper machine.

For more detailed information, please visit our official website: Durable Cast Iron Guide Roller for Toilet Paper Machines (Spare Part)