Boost Toilet Paper Production with a Highly Efficient Combination Roll

In the demanding world of paper production, particularly for consumer goods like toilet paper, efficiency isn’t just a buzzword; it’s the lifeblood of a profitable operation. Manufacturers are constantly seeking ways to optimize every step, from pulp preparation to final winding. One critical component, often overlooked until it causes issues, is the combination roll. This spare part plays a pivotal role in the forming and dewatering sections of a toilet paper machine, directly influencing speed, quality, and ultimately, output. Frankly speaking, the performance of this single part can have a cascading effect on your entire production line. Investing in a high-quality, highly efficient combination roll for toilet paper machines is not merely a replacement strategy; it’s an upgrade that can redefine your machine’s capabilities and significantly impact your bottom line. Without peak performance from this essential roll, achieving desired production targets becomes an uphill battle, leading to frustrating bottlenecks and unnecessary waste.

Understanding the Critical Function of the Combination Roll

The combination roll serves a multifaceted purpose within the wet end of a toilet paper machine. It typically combines the functions of forming and initial dewatering, often working in conjunction with the forming fabric and potentially a vacuum system. As the pulp slurry is introduced onto the forming fabric, the combination roll helps to distribute the fibers evenly, consolidate the sheet, and initiate the crucial process of removing water. This dewatering is essential for sheet integrity and prepares the web for subsequent drying stages. A poorly designed or worn combination roll can lead to uneven dewatering, which manifests as inconsistent sheet caliper, poor formation, and even web breaks. Have you ever wondered why some rolls seem to perform flawlessly while others are a constant source of trouble? Often, the difference lies in the precision engineering, material quality, and surface finish of the roll. A sub-optimal roll restricts water removal, forcing the machine to run slower or consume more energy in the dryers, directly increasing operational costs and limiting overall throughput. Ensuring this part functions optimally is non-negotiable for maintaining a high-speed, high-quality production environment.

The Impact of Roll Design on Dewatering Efficiency

The effectiveness of the combination roll in dewatering is heavily dependent on its design, particularly its surface pattern and material composition. Early designs might have been simpler, but modern highly efficient combination rolls feature intricate patterns, often grooved or drilled, to facilitate rapid and controlled water removal. The geometry of these patterns – the depth, width, and spacing of grooves or holes – is critical. Too shallow, and water removal is insufficient; too deep or wide, and it can compromise sheet formation or cause fabric wear. Furthermore, the material used for the roll shell, and any covering applied, must withstand constant contact with water, fibers, and chemicals while maintaining dimensional stability under pressure and heat. Many experts agree that the evolution of roll technology, incorporating advanced polymers or specialized coatings, has significantly improved lifespan and performance compared to traditional materials. Selecting a roll with a pattern optimized for your specific furnish and desired sheet properties can dramatically improve water removal rates, allowing for higher machine speeds and reduced energy consumption downstream. This specific aspect of the Highly Efficient Combination Roll for Toilet Paper Machines (Spare Part) is where true value is generated, translating directly into tangible production benefits.

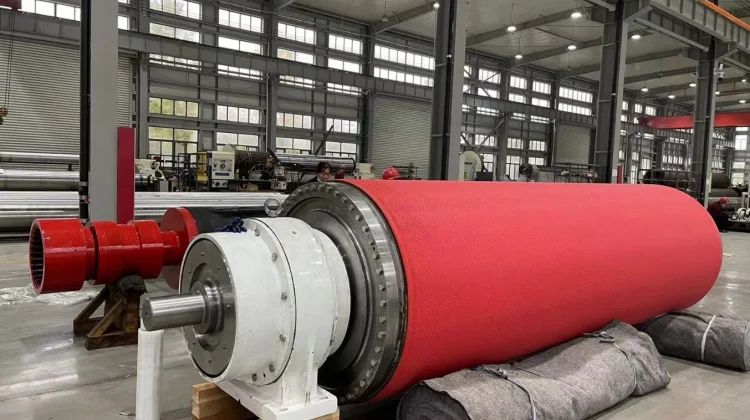

Introducing the Highly Efficient Combination Roll Solution

Recognizing the pivotal role and potential limitations of standard combination rolls, manufacturers have developed advanced solutions specifically designed for enhanced performance. The Highly Efficient Combination Roll for Toilet Paper Machines (Spare Part) represents the pinnacle of this evolution. These rolls are engineered using state-of-the-art materials and manufacturing techniques to maximize dewatering efficiency and improve sheet quality simultaneously. They are often constructed with lightweight, high-strength composite materials or feature specialized stainless steel alloys with durable, low-friction coatings. The surface patterns are meticulously designed and machined to create optimal vacuum and drainage paths, pulling water away from the forming web quickly and evenly. Unlike generic spare parts, these highly efficient versions are built with the specific demands of high-speed tissue production in mind. They minimize fiber stapling, reduce blinding, and maintain their critical dimensions over extended operating periods, leading to less frequent maintenance and roll changes. It’s worth noting that while the initial investment might be higher than a standard roll, the long-term operational savings and production gains far outweigh the upfront cost, making them a smart strategic choice for any serious tissue producer.

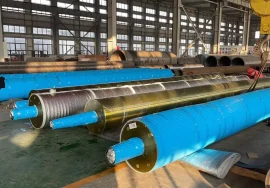

Advanced Materials and Surface Technologies

What truly sets a highly efficient combination roll apart are the advanced materials and surface technologies employed in its construction. Instead of relying on traditional cast iron or basic steel shells, premium rolls often incorporate materials like carbon fiber composites, which offer exceptional strength-to-weight ratios and corrosion resistance. When metallic shells are used, they are typically high-grade stainless steels or alloys specifically chosen for their durability and resistance to chemical attack from process water additives. The roll surface might feature specialized synthetic covers or coatings, engineered to provide superior release properties, reducing sticking and fiber buildup. Furthermore, advanced machining processes, such as precision drilling or laser etching, are used to create the intricate dewatering patterns with extremely tight tolerances. This level of precision ensures consistent performance across the entire width of the roll and throughout its lifespan. This focus on material science and manufacturing accuracy is crucial for a part that operates under constant pressure and moisture, distinguishing a top-tier combination roll spare part from lesser alternatives. Investing in these material advancements ensures a longer service life and consistent, high-level performance.

Measurable Gains in Production Metrics

The benefits of implementing a highly efficient combination roll are not just theoretical; they translate into concrete improvements in key production metrics. Firstly, improved dewatering means the sheet enters the press and dryer sections with a lower moisture content. This directly reduces the energy required for drying, which is often the most energy-intensive part of the paper machine. Lower drying energy equals significant cost savings. Secondly, faster and more uniform dewatering allows the machine to potentially run at higher speeds without compromising sheet quality or risking web breaks. Increased speed means higher throughput and greater overall production volume. Thirdly, consistent sheet formation and quality reduce off-specification product and waste. Fewer web breaks mean less downtime, leading to improved machine uptime percentage – a critical metric for profitability. I’ve found that facilities upgrading to these types of rolls often see a noticeable reduction in operational bottlenecks and a smoother running machine. The impact extends beyond just the roll itself, positively influencing fabric life, press section efficiency, and even winder performance due to a more consistent web.

Optimizing Throughput and Reducing Downtime

One of the most compelling advantages of using a premium combination roll spare part is its direct contribution to optimizing machine throughput and minimizing costly downtime. A standard or worn roll can become a bottleneck, limiting the maximum speed at which the machine can operate effectively due to insufficient dewatering or poor sheet handling. By enhancing dewatering and improving sheet release, a highly efficient roll removes this limitation, allowing operators to potentially increase machine speed and boost overall production volume. Furthermore, issues like roll blinding (clogging of drainage holes) or surface wear on inferior rolls require frequent cleaning or replacement, leading to planned and unplanned downtime. The advanced materials and surface technologies used in highly efficient rolls resist blinding and wear far better, extending the time between maintenance cycles and significantly reducing unplanned stoppages. Frankly speaking, every minute a paper machine is down is a minute of lost production and revenue. Minimizing downtime by investing in reliable, high-performance spare parts like the Highly Efficient Combination Roll is one of the smartest operational decisions a mill can make to protect its profitability.

Selecting the Right Combination Roll for Your Machine

Choosing the correct highly efficient combination roll requires careful consideration, as it’s not a one-size-fits-all solution. Several factors must be taken into account to ensure optimal performance for your specific toilet paper machine and product requirements. Firstly, the size and specifications of the roll must match your machine’s design precisely – diameter, face length, shaft configuration, and bearing journals are critical. Secondly, the design of the dewatering pattern should be evaluated based on your furnish characteristics (pulp type, freeness) and target machine speed. Some patterns are better suited for high-speed operation, while others might be optimized for specific fiber types. Thirdly, consider the operational environment – temperature, chemical use, and vacuum levels all influence material selection and longevity. It’s often beneficial to consult with experts who understand both roll technology and tissue machine dynamics to make an informed decision. They can help analyze your current performance data and recommend a combination roll spare part designed to address your specific challenges and help you achieve your production goals more effectively. Don’t just replace the old roll; upgrade to a solution tailored for efficiency.

Long-Term Value and Investment Protection

While the initial purchase price of a highly efficient combination roll may be higher than a standard replacement part, it’s essential to view this as a strategic investment in your machine’s future performance and reliability. The enhanced durability and resistance to wear and corrosion mean a significantly longer service life compared to conventional rolls, reducing the frequency and cost of replacements over time. The operational savings achieved through reduced energy consumption for drying, minimized waste from web breaks or off-spec product, and increased machine uptime translate into substantial cost reductions that quickly offset the initial investment. Furthermore, the ability to potentially increase machine speed directly boosts revenue potential. Investing in high-quality spare parts like a premium Highly Efficient Combination Roll helps protect your overall investment in the paper machine itself, ensuring it can operate at peak efficiency for years to come. It’s not just about fixing a problem; it’s about proactively enhancing your machine’s capability and ensuring sustainable, profitable production.

In conclusion, the combination roll is far more than just another spare part; it’s a critical component that significantly impacts the efficiency and profitability of your toilet paper production line. Upgrading to a Highly Efficient Combination Roll for Toilet Paper Machines offers tangible benefits, from improved dewatering and reduced energy costs to increased machine speed and minimized downtime. By carefully selecting a roll designed with advanced materials and optimized dewatering patterns, you can unlock the full potential of your equipment, reduce operational headaches, and secure a competitive advantage. Don’t wait for a worn-out roll to cause costly disruptions; consider the long-term value of investing in high-performance spare parts today to ensure your machine operates at its absolute best.

For more detailed information, please visit our official website: Highly Efficient Combination Roll for Toilet Paper Machines (Spare Part)