Choosing the Right Paper Machine Roll: Key Factors to Consider

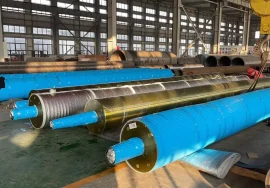

When it comes to the heart of paper production, the paper machine rolls play an undeniably critical role. These seemingly simple cylindrical components are, in reality, sophisticated pieces of engineering, each designed for a specific task within the complex sequence of papermaking. From forming and pressing to drying and calendering, every roll contributes significantly to the final quality, efficiency, and even the profitability of the paper machine operation. Choosing the right roll isn’t merely a matter of picking one that fits; it’s a strategic decision that impacts everything from energy consumption and maintenance costs to the very characteristics of the paper being produced. Franky speaking, getting this choice wrong can lead to costly downtime, premature wear, and subpar product quality. This article dives deep into the essential elements you absolutely must consider when selecting paper machine rolls, ensuring you make informed decisions that optimize your process and outcomes. Have you ever stopped to think about the immense pressure and varying temperatures these rolls endure daily? It’s quite remarkable when you consider the environment they operate in, pushing the boundaries of material science and engineering design in a continuous process that runs 24/7 in many mills. Understanding these pressures and the specific demands of your machine’s position is the first step towards making the right choice, a step that requires careful analysis and attention to detail.

Understanding the Specific Role and Position in Choosing the Right Paper Machine Roll

One of the most fundamental factors in choosing the right paper machine roll is understanding its exact function and location within the paper machine. A roll in the forming section, for instance, faces vastly different challenges compared to a roll in the press section or the calender. Forming rolls, like breast rolls, often operate under high moisture conditions and need to facilitate efficient water removal while supporting the nascent paper web without damaging it. This demands specific surface properties and internal designs to manage water flow and minimize vibration. Press rolls, on the other hand, are subjected to enormous linear loads designed to squeeze water out of the web. This requires extreme mechanical strength, precise crown profiles, and often specialized coverings to prevent crushing the sheet or causing uneven moisture profiles. Calender rolls, used for finishing the paper surface, must withstand high temperatures and pressures to impart smoothness, gloss, or other desired characteristics. Their material and surface finish are paramount for achieving the required paper properties. Interestingly enough, even seemingly less critical rolls, like guide rolls or reel spool rolls, have specific requirements related to web tension control, balancing, and wear resistance. Ignoring the unique demands of each position is a common pitfall that can lead to suboptimal performance and shortened roll lifespan. Therefore, a detailed analysis of the operating environment – including temperature, humidity, chemical exposure, and mechanical stresses – specific to the roll’s intended position is non-negotiable. This granular understanding forms the bedrock of the entire selection process, influencing material choices, covering types, and even internal construction like cooling or heating channels.

Let’s delve a bit deeper into the press section as an example, highlighting how the specific role influences the roll choice. Press rolls operate in pairs, creating nips that dewater the paper web. Depending on the press configuration (e.g., suction press, plain press, shoe press), the requirements for the rolls differ significantly. A suction press roll needs thousands of precisely drilled holes and a robust shell capable of handling vacuum pressures and the mechanical load. The covering needs to be wear-resistant and tolerant of chemicals often used in papermaking. A shoe press roll, which uses a long shoe instead of a cylindrical roll to apply pressure over an extended dwell time, requires a special, highly durable covering capable of withstanding the intense friction and load from the shoe. The mating roll in a shoe press nip also has unique requirements, often needing a hard, smooth surface. See how specific the needs become based on the exact function? It’s not just ‘a roll’; it’s ‘a specific type of roll for a specific type of press nip operating under these exact conditions’. This level of detail is crucial. Furthermore, consider the speed of the machine; faster machines impose higher dynamic loads and require more precise balancing and potentially different bearing arrangements than slower machines. The position dictates function, and function dictates design parameters – it’s a cascading effect that begins with a thorough understanding of where the roll will operate and what it needs to achieve.

Material Selection: A Cornerstone in Choosing Paper Machine Rolls

The material composition of a paper machine roll, including both the core shell and any applied coverings, is absolutely critical and stands as a major factor in the selection process. The right material must withstand the harsh conditions of its specific location within the paper machine – we’re talking about combinations of high pressure, extreme temperatures, corrosive chemicals, abrasion, and fatigue stresses. Historically, cast iron and steel have been the backbone for roll shells due to their mechanical strength and stability. However, advancements in metallurgy and material science have introduced a range of specialized alloys designed for improved corrosion resistance, lighter weight, or enhanced durability in specific environments. The choice of shell material impacts the roll’s rigidity, its thermal properties, and its overall lifespan. For instance, in sections with high chemical exposure, stainless steel or other corrosion-resistant alloys might be necessary, even if they come at a higher initial cost, to prevent premature degradation and potential failure. The internal structure, whether solid, hollow, or with complex internal channels for heating or cooling, also depends heavily on the chosen material’s properties and the required operational performance. A heavy, solid roll might be suitable for certain applications, while a lighter, hollow roll could be preferred to reduce load on bearings and save energy, provided it maintains the necessary strength and stiffness.

Beyond the core shell, the roll covering is perhaps even more varied and critical to performance. Coverings are typically made of polymers, composites, ceramics, or even specialized metal coatings, each offering distinct properties. The covering is the part of the roll that directly interacts with the paper web and often the opposing roll or component (like a doctor blade). Its surface hardness, texture, release properties, chemical resistance, and thermal conductivity are paramount. For example, a soft rubber covering might be ideal for a press nip to create a wider contact area and improve dewatering, while a hard ceramic coating might be necessary on a calender roll to impart a high gloss finish and resist wear from abrasive fillers in the paper. Composite coverings offer a blend of properties, often providing lighter weight, improved corrosion resistance, and tuning possibilities for specific nip characteristics. Frankly speaking, selecting the covering involves balancing numerous trade-offs. A harder covering might last longer against wear but could potentially damage the paper or the opposing roll; a softer covering might be gentle on the sheet but wear out faster or be susceptible to chemical attack. This decision requires a deep understanding of the paper grade being produced, the operating parameters, and the desired roll performance characteristics. Supplier expertise here is invaluable, as they can recommend materials based on extensive experience and testing data in similar applications. It’s worth noting that even the adhesion between the covering and the core is a critical engineering challenge, ensuring the covering remains intact under extreme stress.

Operating Conditions and Their Impact on Choosing Paper Machine Rolls

The specific operating conditions under which a paper machine roll must perform are non-negotiable considerations when making your selection. These conditions include speed, temperature, pressure (linear load), chemical environment (pH, presence of corrosive substances, additives), and potential for abrasion from the paper web or contaminants. Each of these factors places unique demands on the roll material, covering, and overall design. A roll operating at high speeds requires exceptional dynamic balance to prevent vibration, which can lead to uneven wear, bearing damage, and quality defects in the paper. High temperatures, whether from the process itself (like in drying or calendering) or generated by friction, necessitate materials and coverings that can maintain their mechanical properties and dimensional stability without degrading. Conversely, rolls operating in cold environments might require special considerations for thermal expansion or contraction. The pressure applied in press nips or calender stacks dictates the required structural strength of the roll shell and the load-bearing capacity of the covering. Choosing a roll with insufficient mechanical strength for the applied load is a recipe for disaster, potentially leading to deflection issues, cracking, or even catastrophic failure. Similarly, a covering not designed for the specific linear load will quickly deform or wear out.

The chemical environment is another critical factor. Paper stock often contains various chemicals, including sizing agents, fillers, dyes, and process water treatments, which can be corrosive or cause swelling or degradation of certain materials, particularly polymer coverings. Selecting materials and coverings with appropriate chemical resistance is essential for preventing premature failure and ensuring consistent performance. Abrasion, caused by fillers like clay or titanium dioxide in the paper web, or by doctor blades and showers, is a constant challenge. Rolls in abrasive environments require hard, wear-resistant coverings or shell materials. In my experience, overlooking the cumulative effect of even mild chemical exposure combined with abrasion can significantly shorten roll life. Furthermore, the presence of foreign objects or ‘junk’ in the paper stock can cause dents or nicks on the roll surface, requiring materials and coverings that can withstand impact or be easily repaired. It’s also important to consider the cleaning methods used, as harsh cleaning chemicals or abrasive cleaning techniques can also impact roll longevity. Considering the entirety of the operating envelope – the range of speeds, temperatures, pressures, and chemical exposures the roll will experience – allows for a much more accurate and effective selection process. Failure to account for extreme or fluctuating conditions can lead to performance issues or premature replacement. How thoroughly have you documented the full range of conditions your rolls face?

Lifetime, Maintenance, and Total Cost of Ownership: Long-Term Factors in Choosing Paper Machine Rolls

While initial purchase price is undoubtedly a consideration, focusing solely on it when choosing paper machine rolls is often shortsighted. A more comprehensive approach involves evaluating the total cost of ownership (TCO) over the expected lifespan of the roll. This includes the purchase price, but also accounts for installation costs, energy consumption (related to weight and bearing friction), maintenance requirements (grinding, covering repair/replacement), repair costs, and the cost of downtime incurred during maintenance or unexpected failure. A roll that is initially more expensive but lasts significantly longer, requires less frequent maintenance, or consumes less energy can prove to be far more economical in the long run. For instance, a premium covering with enhanced wear resistance might cost more upfront but could extend the time between regrinds or replacements, ultimately reducing maintenance labor and downtime costs. Similarly, a roll designed for optimal thermal transfer could reduce energy consumption in heated or cooled sections, contributing to lower operating expenses over its lifetime. Considering the full lifecycle of the roll, from procurement to eventual decommissioning, provides a much clearer picture of its true economic value. Suppliers often provide estimates for expected roll life and maintenance intervals under specified operating conditions, which can help in this TCO calculation.

Maintenance requirements vary significantly depending on the roll type, material, and covering. Some coverings require periodic regrinding to maintain their profile and surface finish, while others might need repair for localized damage or eventual full replacement. The ease and cost of these maintenance procedures are important factors. Can the regrinding be done on-site, or does the roll need to be shipped off-site? How long does the process take, and what is the associated cost of labor and materials? The susceptibility of the roll or covering to damage from doctor blades, web breaks, or tramp material also influences maintenance frequency and cost. A robust design that minimizes the risk of damage can save significant amounts of money over time. Furthermore, the energy efficiency of the roll, particularly rotating weight and bearing design, contributes to operating costs. Lighter rolls and low-friction bearings can reduce power consumption. Many experts agree that prioritizing reliability and longevity over minimum initial cost is a hallmark of well-managed paper machine operations. The cost of unplanned downtime – lost production time, wasted materials, and labor for emergency repairs – far outweighs the price difference between a standard roll and a premium, more durable option. When selecting rolls, it’s wise to inquire about expected service life, recommended maintenance practices, and typical repair costs under your specific operating conditions. These factors are just as important as the initial price tag.

Supplier Expertise and Support in Choosing Paper Machine Rolls

Selecting the right partner for your paper machine roll needs is just as crucial as the technical specifications of the rolls themselves. A reputable supplier brings not just manufacturing capabilities but also invaluable expertise and support that can significantly influence your decision-making process and the long-term performance of your rolls. They possess deep knowledge of various roll types, materials, coverings, and their behavior under diverse operating conditions across different paper grades. They can analyze your specific machine parameters, paper requirements, and operational challenges to recommend solutions that are truly optimized for your application. This goes beyond simply providing a catalog; it involves technical consultation, performance prediction based on experience and simulation, and sometimes even custom design work. A good supplier acts as a partner, helping you navigate the complexities of material selection, profile design, and covering choice to achieve your performance goals, whether that’s improving dewatering, enhancing surface finish, increasing speed, or reducing maintenance. They understand the nuances that might not be immediately obvious from surface-level specifications. They can offer insights into the latest technological advancements in roll materials and coverings, ensuring you have access to the most suitable options available.

Beyond the initial selection and procurement, the support offered by the supplier throughout the roll’s lifecycle is vital. This includes assistance with installation, guidance on proper operation and maintenance practices, troubleshooting performance issues, and efficient, high-quality services for repair, regrinding, and recovering. The availability of rapid repair services can drastically reduce downtime in the event of unexpected damage. A supplier with well-equipped service centers and experienced technicians can restore damaged rolls quickly and effectively, minimizing production losses. Furthermore, ongoing technical support can help you optimize roll performance over time, perhaps by suggesting adjustments to operating parameters or maintenance schedules based on actual wear patterns. Consider the supplier’s track record, their reputation in the industry, their technical capabilities, and their commitment to customer support when making your choice. Asking for references or case studies relevant to your type of machine and paper grade can provide valuable insights. Investing in a relationship with a knowledgeable and reliable supplier is, in my experience, a key factor in ensuring the sustained success and efficiency of your paper machine operations. They are not just selling a product; they are providing a solution and a partnership aimed at optimizing your entire roll system. Have you evaluated your current or potential suppliers based on their technical support capabilities?

In conclusion, choosing the right paper machine roll is a multifaceted decision that demands careful consideration of several key factors derived directly from the roll’s purpose and environment. It’s not about a single magic bullet but rather a holistic evaluation of the roll’s specific position and function within the machine, the optimal material and covering selection to withstand operating conditions, a realistic assessment of the total cost of ownership over its lifespan, and the support offered by the supplier. Each roll, from the forming section to the reel, presents a unique set of challenges and requirements. By thoroughly analyzing these factors – understanding the demands of the position, selecting materials and coverings appropriate for the pressures, temperatures, and chemicals involved, weighing the long-term costs of maintenance and energy against the initial investment, and leveraging the expertise of a trusted supplier – you can make choices that enhance machine performance, improve paper quality, reduce operational costs, and minimize downtime. Our company understands these complexities and offers solutions tailored to the specific needs of your paper machine, helping you navigate the critical factors involved in selecting the right roll for every application. Choosing wisely today ensures smoother, more profitable operations tomorrow.

For more detailed information, please visit our official website: Choosing the Right Paper Machine Roll: Key Factors to Consider