Expertise in Paper Machine Rollers Manufacturing

In the intricate world of papermaking, every component plays a crucial role in ensuring quality and efficiency. From the initial pulp preparation to the final winding of the paper reel, the machinery must operate flawlessly under demanding conditions. Among the most critical elements are the rollers that guide, press, and dry the paper web. These unsung heroes endure immense pressure, high temperatures, and constant abrasion, making their design, manufacturing, and maintenance paramount. The performance of a paper machine is, to a significant extent, a direct reflection of the quality of its rollers. Choosing the right supplier for these vital components is not merely a procurement decision; it’s a strategic investment in the reliability and output of your entire operation. This is precisely why partnering with a reputable and experienced

paper machine rollers manufacturer

is absolutely essential.

The Critical Engineering Behind Papermaking Rollers

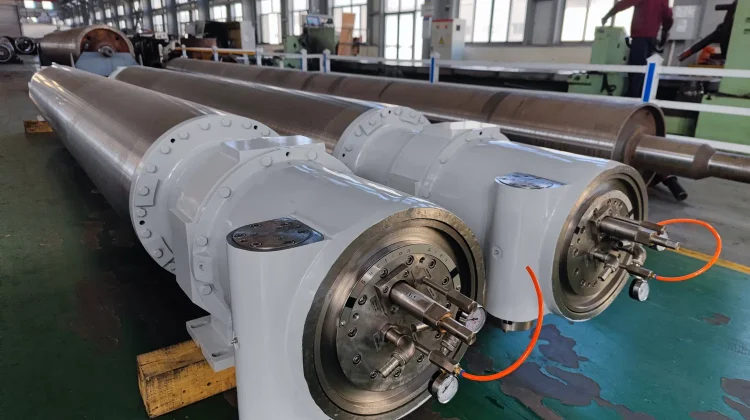

Have you ever stopped to consider the sheer engineering marvel that is a modern paper machine roller? It’s far more than just a simple cylinder. Each roller is a precisely engineered component designed for specific functions within the machine. Press rollers, for instance, must withstand thousands of pounds per linear inch of pressure to remove water from the paper web, while dryer cylinders transfer heat efficiently and evenly across the web width. Guide rollers, though seemingly less complex, must maintain perfect alignment and tension to prevent tears or wrinkles. The materials used, the internal structure, the surface finish, and the external covers or coatings are all meticulously selected and applied to optimize performance and durability. Frankly speaking, the complexity involved in designing and manufacturing these rollers to meet the rigorous demands of continuous, high-speed papermaking cannot be overstated. It requires deep knowledge of mechanics, metallurgy, fluid dynamics, and thermal science.

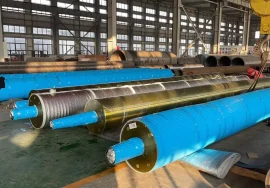

Materials Science and Precision in Roller Construction

The foundation of a high-quality paper machine roller lies in the choice of materials and the precision of its construction. Typically, the core of the roller is made from high-grade steel or cast iron, selected for its strength, rigidity, and thermal properties. However, the real magic often happens on the surface. Depending on the application, rollers may be covered with various rubber or polymer compounds, or coated with specialized materials like ceramics, carbides, or hard chrome. These coverings and coatings provide crucial properties: wear resistance, corrosion protection, specific surface energy for optimal web release, and thermal insulation or conductivity as needed. Precision machining is equally vital. Rollers must be ground and polished to extremely tight tolerances for concentricity, straightness, and surface finish. Dynamic balancing is mandatory to prevent vibration at high operating speeds, which can lead to web breaks, uneven moisture profiles, and premature bearing failure. A truly expert paper machine rollers manufacturer understands these nuances intimately.

Partnering for Performance: What to Look for in a Manufacturer

Selecting the right paper machine rollers manufacturer is a decision that will impact your operational efficiency and product quality for years to come. What are the key attributes that distinguish a top-tier manufacturer from the rest? Experience is certainly high on the list; a company with decades in the industry has encountered and solved a vast array of challenges. Technical expertise is non-negotiable – they must possess the engineering talent capable of designing rollers for new applications and diagnosing issues with existing ones. Look for a manufacturer with robust quality control processes at every stage, from raw material inspection to final dimension checks and balancing. Customization capability is also critical; a one-size-fits-all approach simply doesn’t work in papermaking. Can they design and manufacture

custom paper machine rollers

Beyond Manufacturing: Support and Technical Consultation

A leading paper machine rollers manufacturer offers more than just the physical product; they provide invaluable technical support and consultation. This includes assisting you in selecting the most appropriate roller type and cover material for a given position in your machine, analyzing reasons for premature wear or failure, and offering recommendations for optimization. They should be able to provide detailed specifications, installation guidelines, and maintenance best practices. Interestingly enough, some of the most significant improvements in paper machine performance can come from relatively small adjustments based on expert advice regarding roller setup and care. A manufacturer who invests in understanding your specific operational challenges is a partner, not just a supplier. This collaborative approach is fundamental to achieving continuous improvement in your papermaking process and maximizing the lifespan and effectiveness of your rollers.

The Role of Advanced Covers and Surface Treatments

The surface of a paper machine roller is where it directly interacts with the paper web, and therefore, its condition is paramount. Advanced rubber and polymer covers, along with specialized coatings, are engineered to provide specific functionalities. For press rollers, covers are designed to optimize dewatering while minimizing sheet crushing and unevenness. Dryer cylinder surfaces or coatings facilitate efficient heat transfer and prevent sticking. Guide roller covers ensure consistent grip without damaging the delicate wet web. These coverings are not merely protective layers; they are active participants in the papermaking process, influencing everything from moisture profile and sheet strength to energy consumption and machine speed. The development of these materials involves significant research and development, and a capable

paper machine rollers manufacturer

Ensuring Longevity Through Refurbishment and Maintenance

Given the significant investment they represent and the stresses they endure, the lifespan of paper machine rollers is a key economic factor. While high-quality manufacturing is the starting point, proper maintenance and timely refurbishment are essential to maximize roller life and performance. A comprehensive service offering from your manufacturer should include inspection services to assess the condition of rollers in the mill, regrinding and resurfacing capabilities to restore optimal profiles and finishes, and the ability to replace worn or damaged covers and bearings. Services like

paper machine roller repair services

Actionable Steps for Selecting Your Next Manufacturer

So, how do you go about finding the right paper machine rollers manufacturer for your specific needs? Start by assessing your current challenges. Are you experiencing frequent cover failures, uneven profiles, vibration issues, or poor dewatering? Clearly defining these problems will help you identify a manufacturer with relevant expertise. Request detailed information about their manufacturing processes, quality control procedures, and the materials they use. Ask for case studies or references from other paper mills. Inquire about their technical support capabilities – can they provide on-site assistance or remote diagnostics? Don’t shy away from discussing your specific machine configuration and paper grades; a good manufacturer will welcome the opportunity to demonstrate their ability to provide tailored solutions. Considering the critical nature of these components, a thorough vetting process is not just advisable, it’s imperative.

The Impact of Quality Rollers on Mill Productivity

Ultimately, the performance of your paper machine rollers has a direct and significant impact on your mill’s overall productivity and profitability. High-quality, precisely manufactured, and properly maintained rollers contribute to faster machine speeds, improved paper quality (better uniformity, fewer defects), reduced energy consumption (efficient dewatering and drying), and minimized unplanned downtime. Conversely, failing or subpar rollers can lead to web breaks, off-spec paper, increased maintenance costs, and substantial production losses. The initial cost of a premium roller from a reputable

paper machine rollers manufacturer

Conclusion: Making the Right Choice for Your Operations

Choosing the right supplier for paper machine rollers is a strategic decision that underpins the efficiency and success of your entire papermaking operation. It requires looking beyond price to evaluate expertise, quality, customization capabilities, and long-term support. A manufacturer who understands the unique demands of your process, utilizes advanced materials and precision engineering, and offers comprehensive lifecycle support from initial manufacturing to refurbishment, is a partner worth investing in. The performance and longevity of your rollers directly correlate with your machine’s uptime, paper quality, and profitability. By selecting a manufacturer committed to excellence and innovation in

paper machine rollers manufacturing

, you are laying the foundation for consistent, high-quality production and operational success. Make this critical choice with due diligence and foresight.

For more detailed information, please visit our official website: paper machine rollers manufacturer