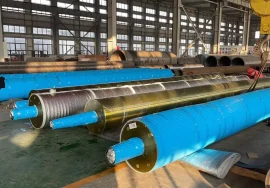

Durable Cast Iron Guide Roller for Toilet Paper Machines (Spare Part)

When it comes to maintaining the efficiency of toilet paper machines, the role of durable spare parts cannot be overstated. Among these, the cast iron guide roller stands out as a critical component that ensures smooth operation and longevity. But what makes these rollers so essential, and why is cast iron the material of choice? Let’s dive into the details.

Why Cast Iron is the Ideal Material for Guide Rollers

Cast iron has long been favored in industrial applications due to its exceptional durability and resistance to wear. For toilet paper machines, where rollers endure constant friction and pressure, cast iron provides the necessary strength to withstand heavy usage. Unlike softer materials, cast iron doesn’t deform easily, ensuring consistent performance over time. Additionally, its natural lubricity reduces friction, which is crucial for maintaining the delicate balance required in paper production.

Key Advantages of Cast Iron in Industrial Settings

Beyond durability, cast iron offers several other benefits that make it ideal for guide rollers in toilet paper machines:

- High Load Capacity: Cast iron can handle significant weight without bending or breaking, making it perfect for high-speed production lines.

- Corrosion Resistance: The material’s natural resistance to rust and corrosion extends the lifespan of the rollers, even in humid environments.

- Thermal Stability: Cast iron maintains its integrity under varying temperatures, preventing warping or cracking during operation.

How Guide Rollers Impact Toilet Paper Machine Efficiency

Guide rollers play a pivotal role in the paper manufacturing process by ensuring the material moves smoothly through the machine. A well-designed cast iron guide roller minimizes slippage, reduces paper jams, and maintains consistent tension. This not only improves the quality of the final product but also reduces downtime for maintenance. In fact, many manufacturers report a noticeable increase in production speed and a decrease in waste when using high-quality cast iron rollers.

Common Issues with Low-Quality Rollers

Using subpar rollers can lead to a host of problems, including:

- Uneven paper feeding, resulting in wrinkles or tears

- Increased wear on other machine components due to misalignment

- Frequent breakdowns, leading to costly repairs and lost production time

Selecting the Right Cast Iron Guide Roller for Your Machine

Not all cast iron guide rollers are created equal. When choosing a spare part for your toilet paper machine, consider the following factors:

- Precision Engineering: The roller should be machined to exact specifications to ensure a perfect fit and optimal performance.

- Surface Finish: A smooth, polished surface reduces friction and prevents paper snagging.

- Compatibility: Ensure the roller is designed for your specific machine model to avoid installation issues.

Why Our Cast Iron Guide Rollers Stand Out

At our company, we specialize in manufacturing high-quality cast iron guide rollers tailored for toilet paper machines. Our products undergo rigorous testing to guarantee durability, precision, and reliability. Whether you’re looking to replace a worn-out roller or upgrade your machine’s components, our spare parts are designed to deliver long-term value.

Maintenance Tips to Extend Roller Lifespan

To maximize the lifespan of your cast iron guide rollers, regular maintenance is key. Here are some practical tips:

- Clean the rollers regularly to remove paper dust and debris.

- Lubricate bearings and moving parts to reduce friction and wear.

- Inspect for signs of wear or damage and replace parts as needed.

When to Replace Your Guide Rollers

Even the most durable rollers will eventually need replacement. Watch for these signs:

- Visible cracks or chips in the roller surface

- Increased noise or vibration during operation

- Frequent paper jams or misalignment issues

Conclusion: The Importance of Quality Spare Parts

Investing in durable cast iron guide rollers for your toilet paper machines is a smart decision that pays off in the long run. These spare parts not only enhance machine efficiency but also reduce maintenance costs and downtime. By choosing high-quality components and following proper maintenance practices, you can ensure your production line runs smoothly for years to come.

For more detailed information, please visit our official website: Durable Cast Iron Guide Roller for Toilet Paper Machines (Spare Part)