How Our Rolls Help You Achieve Consistent Paper Quality

Achieving consistent paper quality isn’t just a goal in paper manufacturing; it’s the bedrock of a successful operation. Variability can lead to wasted materials, dissatisfied customers, and significant production inefficiencies. Every stage of the papermaking process, from forming the web to drying and finishing, relies heavily on the performance of critical components, and perhaps none are as fundamental as the rolls. These seemingly simple cylinders guide, press, dewater, and transport the paper web under immense stress, pressure, and temperature variations. Their condition, design, and material properties directly influence the uniformity of the paper web’s moisture content, caliper, density, and surface characteristics. Think about it: if a roll isn’t perfectly cylindrical or has an uneven surface, how can the paper passing over it ever be uniform? This is precisely where the quality and performance of the rolls become paramount. They are the silent workhorses, yet their impact on the final product’s consistency is anything but silent. Ensuring that each sheet, each reel, each batch of paper meets the required specifications time after time hinges significantly on the reliability and precision of the rolls used throughout the machine. Without well-engineered, properly maintained rolls, the pursuit of consistent quality becomes an uphill, often impossible, battle, leading to unpredictable outcomes and jeopardizing brand reputation. Frankly speaking, the rolls are the backbone of your quality control efforts, even before you get to the testing lab.

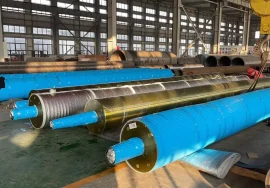

Precision Manufacturing: A Foundation for Consistent Paper Quality

The journey towards consistent paper quality begins long before a fiber touches a roll, specifically in the manufacturing precision of the rolls themselves. To be honest, this is a non-negotiable aspect. The geometric accuracy of a roll – its diameter uniformity, cylindricity, and dynamic balance – directly translates to the uniformity of the forces and distances applied to the paper web. Imagine a press roll with even a slight taper or eccentricity; it would apply uneven pressure across the width of the web, resulting in variations in dewatering, density, and caliper. These variations are then locked into the paper structure, becoming almost impossible to correct downstream. Similarly, guide rolls must be perfectly cylindrical and run true to ensure the web tracks correctly and uniformly, preventing wrinkles or uneven tension that could distort the sheet. Our rolls are manufactured to incredibly tight tolerances, utilizing advanced machining and grinding techniques to ensure near-perfect geometry. This meticulous attention to detail in the manufacturing phase is not just about crafting a durable component; it’s about building a foundation for repeatable, predictable interactions with the paper web. It ensures that when pressure is applied, it’s uniform; when temperature is transferred, it’s even; and when the web is guided, it moves smoothly without distortion. This fundamental precision is the first, critical step our rolls provide in helping you achieve that all-important consistent paper quality, setting the stage for reliable performance throughout their operational life.

Maintaining Geometric Integrity Under Stress

Achieving initial precision is one thing; maintaining that precision under the harsh, dynamic conditions of a paper machine is another challenge entirely. Rolls are subjected to tremendous mechanical loads, thermal cycling, and chemical exposure. Press rolls can experience nip pressures measured in hundreds of pounds per linear inch, while dryer rolls operate at high temperatures. These stresses can cause deflection, distortion, and wear over time, all of which compromise the roll’s original geometry. A roll that deflects unevenly under load will create non-uniform nip pressure profiles, leading to streaks or variations in moisture and density. Rolls designed to resist deformation, either through robust internal construction, appropriate material selection, or specialized crown profiles, are essential for mitigating these issues. Our engineering focuses heavily on predicting and minimizing operational deflection and thermal expansion. We select materials and design internal structures that maintain the roll’s critical dimensions and shape even under peak operating stresses. Furthermore, features like optimized internal cooling or heating channels help manage temperature gradients within the roll body, preventing thermal distortion. This focus on maintaining geometric integrity throughout the roll’s operational cycle is crucial because even minor deviations can introduce inconsistencies into the paper web, highlighting the critical role our rolls play not just in starting right, but staying right, ensuring consistent paper quality run after run, year after year.

Material Science and Surface Integrity: Keys to Reliable Paper Production

Beyond just shape and size, the materials used for roll bodies and, perhaps even more critically, their surfaces, play a pivotal role in achieving consistent paper quality. The interaction between the roll surface and the paper web, felts, or fabrics is complex and highly influential. Consider pick-up rolls or press rolls, where surface properties like hardness, porosity, and chemical resistance are paramount. A surface that’s too sticky can cause fibers to adhere, leading to web breaks or uneven surface texture on the paper. A surface that wears quickly will rapidly lose its original profile, introducing caliper and density variations. The correct choice of rubber covers, polymer composites, or metallic coatings is not just about durability; it’s about ensuring a stable, predictable interface with the paper web. Different applications demand different surface characteristics – a calender roll requires a smooth, hard surface for gloss and smoothness development, while a couch roll needs optimal dewatering properties. Our material scientists work tirelessly to develop and select materials and coatings that are best suited for specific positions in the paper machine. We consider factors like abrasion resistance, chemical inertness to process additives, resistance to water absorption, and thermal conductivity. The goal is to provide a roll surface that maintains its functional properties over extended periods, minimizing variations introduced by surface degradation. This expertise in material science and surface engineering is fundamental to how our rolls help you achieve consistent paper quality, providing a reliable and unchanging interface for the delicate papermaking process.

Surface Finishes and Coatings for Optimal Interaction

The final surface finish on a roll is just as important as the underlying material. The microscopic texture of a roll surface influences everything from water removal efficiency to the finish applied to the paper. For instance, dryer drum surfaces need to be smooth enough for efficient heat transfer but also resistant to scale build-up. Press roll covers can have specific patterns (grooves, blind drilled holes) or textures designed to optimize water removal under pressure. The longevity and stability of these surface finishes directly impact the consistency of the paper produced. If a press roll cover begins to wear unevenly or grooves become plugged, dewatering will become non-uniform. If a calender roll develops surface imperfections, it will transfer those imperfections to the paper, affecting its smoothness and gloss. Our company invests heavily in surface treatment technologies, including advanced grinding, polishing, and specialized coatings. We apply wear-resistant ceramic coatings, release-enhancing polymer covers, or hard chrome plating, depending on the application’s requirements. These treatments are designed to extend the life of the roll surface, resist wear and chemical attack, and maintain their critical properties run after run. This meticulous attention to surface engineering ensures that the interface between the roll and the paper remains stable and predictable, which is a key factor in how our rolls contribute to your ability to achieve consistent paper quality, minimizing unwanted variations caused by surface changes.

Temperature and Pressure Control: How Rolls Ensure Uniform Conditions

Temperature and pressure are two critical parameters in papermaking, influencing dewatering, drying efficiency, and the final structural properties of the paper. Rolls are often the primary means of applying and controlling these parameters. In the press section, rolls apply immense pressure to squeeze water out of the web. The uniformity of this pressure across the web width, as previously discussed, is paramount for consistent moisture profile and density. High-quality press rolls, designed with appropriate crowning and materials that resist deflection, ensure even pressure distribution. In the dryer section, heated rolls transfer thermal energy to evaporate water. Consistent temperature distribution across the roll face is essential for uniform drying. Cold spots or hot spots on dryer drums lead to uneven moisture content in the final sheet, causing downstream issues like curling, variable strength, and inconsistent printability. Interestingly enough, some rolls also require precise cooling to prevent overheating or manage felt conditioning. Our rolls are engineered with sophisticated internal systems for temperature control, whether it’s steam heating for dryer drums or cooling systems for other applications. We ensure efficient heat transfer and uniform temperature distribution throughout the roll body. Furthermore, our press rolls are designed not only for precise crowning but also considering factors like dynamic behavior under load to maintain uniform nip pressure across varying speeds. By providing reliable and predictable control over temperature and pressure application, our rolls directly enable you to achieve consistent paper quality, eliminating variations that would otherwise arise from non-uniform process conditions.

The Role of Roll Covers in Process Control

It’s worth noting that the roll cover material itself significantly influences temperature and pressure control. Rubber and polymer covers on press rolls, for instance, have specific hardnesses and elastic properties that affect the nip width and pressure profile. A cover that is too hard or too soft, or whose properties change significantly with temperature, can negatively impact pressure uniformity. Similarly, dryer section rolls might utilize specialized coatings that enhance heat transfer efficiency while resisting build-up. The thermal properties of the roll cover and body material dictate how effectively heat is transferred to the web. Non-uniform cover thickness or inconsistencies in material properties can lead to temperature variations on the surface. Our engineers carefully select and apply roll covers with specific, stable physical and thermal properties that are optimized for their intended application. We understand that the cover is not just a protective layer but an active component in controlling process parameters. The quality and consistency of the cover material, combined with precise application techniques, ensure that the roll performs predictably and uniformly. This level of detail in selecting and applying covers is a critical factor in how our rolls help in maintaining the precise temperature and pressure profiles needed for consistent paper quality, minimizing variables introduced by the roll’s surface interaction with the process.

Maintaining Roll Performance Over Time: Longevity and Consistency

The operational life and maintenance requirements of rolls are directly tied to long-term paper quality consistency. Even the most precisely manufactured roll will eventually experience wear, fatigue, or surface degradation. How well it resists these effects and how effectively it can be maintained determines how long it contributes positively to consistent paper quality. Frequent roll changes due to rapid wear introduce variability and downtime. Rolls that require constant grinding or repair disrupt production schedules and can never fully recover their original, perfect state. Durability is not just about cost savings; it’s about sustaining a stable production environment. Rolls made from inferior materials or with poor design can quickly develop issues like vibration, barring (patterned wear), or uneven surface wear, all of which directly cause inconsistencies in the paper web. Our company designs rolls with longevity and ease of maintenance in mind. We use robust materials, apply wear-resistant coatings, and engineer features that minimize stress concentrations. Furthermore, our rolls are designed to be serviceable, allowing for efficient regrinding, resurfacing, or repair when necessary, extending their life cycle while restoring their performance characteristics. Have you ever wondered why some paper machines seem to run flawlessly for years while others struggle with constant quality issues? Often, the difference lies in the reliability and sustained performance of key components like rolls. By providing durable, maintainable rolls, we help reduce unexpected variations and downtime, contributing significantly to your ability to achieve consistent paper quality day in and day out.

The Impact of Preventative Maintenance and Service

While initial design and materials are crucial, the ongoing maintenance of rolls is equally important for sustaining consistent paper quality. Even high-quality rolls benefit from regular inspection, cleaning, and maintenance. Skipping preventative maintenance or using improper servicing techniques can accelerate wear and lead to unexpected failures or gradual performance degradation. Issues like bearing wear, seal leaks, or cover damage, if left unaddressed, will inevitably manifest as inconsistencies in the paper web. Many experts agree that a proactive approach to roll maintenance is essential for maximizing roll life and ensuring stable operation. Our company offers comprehensive service and support programs for our rolls, including inspection guidelines, recommended maintenance schedules, and expert repair services. We can help train your maintenance staff or provide on-site support to ensure rolls are cared for properly, preserving their precision and surface integrity. This focus on supporting the roll throughout its lifecycle is a vital part of how our rolls help you achieve consistent paper quality, ensuring that their contribution to uniformity doesn’t diminish over time. It’s about partnership in quality assurance, providing not just a piece of hardware, but a long-term solution for reliable paper production.

Addressing Common Challenges Through Superior Roll Technology

Paper manufacturing lines present numerous challenges that can disrupt consistency, from vibration and barring to sheet sticking and uneven moisture profiles. Interestingly enough, many of these issues can be directly traced back to roll performance. Vibration, for example, can be caused by roll imbalance, bearing issues, or uneven roll wear, leading to caliper variations and printing problems. Barring, a cyclical pattern of wear on roll covers, imprints itself onto the paper web, creating visible and measurable density or caliper variations. Sheet sticking to rolls disrupts the web path and can cause breaks or surface defects. Uneven moisture profiles, as discussed, often stem from inconsistent dewatering or drying, directly influenced by press and dryer roll performance. Superior roll technology is specifically designed to mitigate these common headaches. Our rolls feature optimized designs to minimize vibration and enhance stability, even at high speeds. We utilize advanced materials and coatings that resist barring and reduce the propensity for sticking. Our precision manufacturing and robust construction ensure that rolls maintain their critical geometry and dynamic balance, preventing many common sources of inconsistency. For instance, specialized covers can improve release properties, reducing sticking, while advanced crowning techniques help compensate for roll deflection, ensuring uniform pressure distribution. By engineering solutions directly into our rolls to tackle these persistent challenges, we provide you with tools that actively prevent inconsistencies from occurring, rather than just reacting to them. This proactive approach through advanced roll technology is a fundamental way our rolls help you achieve consistently high paper quality.

Engineering Solutions for Specific Process Points

The demands placed on rolls vary significantly depending on their position in the paper machine. A forming roll faces different challenges than a calender roll or a reel spool. Recognizing these specific needs is crucial for designing rolls that contribute effectively to consistent quality at every stage. For example, forming rolls require excellent release properties and resistance to fiber buildup to ensure a uniform sheet is formed. Press rolls need to withstand high pressure and efficiently dewater the web without causing crushing or unevenness. Dryer drums must efficiently transfer heat while resisting corrosion and maintaining a smooth surface. Calender rolls need to achieve the desired paper smoothness and gloss uniformly across the web width without inducing barring. Our company engineers rolls tailored to the specific demands of each process point. We optimize material selection, surface treatments, internal design (e.g., for heating/cooling or vacuum assistance), and crowning based on the roll’s function and operating conditions. This application-specific engineering ensures that each roll is not just a component but a performance enhancer for its particular stage, contributing maximally to the overall goal of consistent paper quality. By providing specialized roll solutions for each critical position, our rolls offer targeted support for maintaining uniformity throughout the entire papermaking process, addressing challenges with precision-engineered solutions.

The Enduring Value Proposition: Consistent Quality as a Competitive Edge

Ultimately, the discussion about how our rolls help you achieve consistent paper quality boils down to a fundamental business advantage. In today’s competitive market, delivering predictable, high-quality paper isn’t a luxury; it’s a necessity. Customers rely on your product performing the same way every time, whether it’s for printing, packaging, or specialty applications. Inconsistent quality leads to customer complaints, rejected shipments, and damage to your reputation. Conversely, a reputation for consistent quality can open doors to new markets, build stronger customer relationships, and command premium pricing. The investment in high-quality, precision-engineered rolls from a reliable supplier like us is an investment in that competitive edge. It’s about minimizing the variables that can plague a paper machine and maximizing the predictability of the final product. Our rolls provide the stable, reliable foundation necessary for process control and quality assurance. They reduce the likelihood of inconsistencies caused by roll wear, surface degradation, or geometric inaccuracies. This allows your operators to focus on optimizing other process parameters, confident that the rolls are performing as expected. Franky speaking, the return on investment isn’t just measured in roll longevity, but in the tangible business benefits derived from consistently meeting and exceeding customer expectations for paper quality. How significant is consistent quality to your customers, and are your current rolls helping or hindering that goal?

In conclusion, achieving consistent paper quality is a complex undertaking influenced by numerous factors, but the quality and performance of the rolls are undeniably central. From the initial precision of their manufacturing and the careful selection of materials and surface treatments to their ability to maintain geometric integrity under stress and provide reliable temperature and pressure control, rolls are fundamental drivers of uniformity in the paper web. Our commitment to engineering durable, high-performance rolls designed for specific applications and supported by comprehensive service helps mitigate common challenges like wear, vibration, and sticking, all of which can disrupt consistency. By providing rolls that offer sustained performance and predictable interaction with the paper web, we offer a vital component in your pursuit of consistently high paper quality, helping you build a reputation for reliability and excellence in the market. The value our rolls bring is directly tied to your ability to deliver that consistent quality that your customers depend on, solidifying your position as a trusted supplier.

For more detailed information, please visit our official website: How Our Rolls Help You Achieve Consistent Paper Quality