Innovative Roll Coverings for Demanding Papermaking Applications

The world of papermaking is, frankly, a demanding environment. It’s a place where high temperatures, aggressive chemicals, immense pressures, and continuous operation push machinery to its absolute limits. In such a setting, every component must perform flawlessly, and perhaps few are more critical than the roll coverings. These aren’t just simple coatings; they are highly engineered layers designed to interact with the paper web and process fluids under extreme stress. The pursuit of enhanced performance, reduced downtime, and improved quality in this challenging landscape has driven significant innovation in the materials and technologies used for these essential coverings. Understanding the complexities of these “demanding papermaking applications” is the first step in appreciating why “innovative roll coverings” are not just beneficial, but absolutely necessary for modern mill operations.

Understanding the Demanding Nature of Papermaking Environments

Demanding papermaking applications present a unique cocktail of challenges that standard industrial components simply cannot withstand long-term. Think about the sheer scale of the operation: vast paper machines running 24/7, handling thousands of gallons of water per minute, processing fibers, fillers, and various chemical additives. The rolls themselves face incredible loads, often measured in hundreds or even thousands of pounds per linear inch. Temperatures can fluctuate, especially in drying sections, reaching levels that would degrade conventional materials rapidly. Chemically, the process involves everything from acidic pulps to alkaline sizing agents and bleaching chemicals, all of which can attack vulnerable surfaces. Abrasion from fibers and fillers is constant, wearing away at the surface of rolls. To be honest, maintaining consistent nip profiles, preventing sticking, and ensuring efficient dewatering under these relentless conditions requires materials that are incredibly robust, resilient, and specifically engineered for purpose. This inherent toughness is why traditional roll coverings have evolved so dramatically, leading the charge for truly innovative solutions.

The Critical Role of Roll Coverings in Papermaking Performance

Roll coverings are far more than just protective layers; they are active functional components that profoundly influence the papermaking process at every stage. In the press section, for instance, their ability to dewater the paper web efficiently is paramount to reducing energy consumption in the subsequent drying phase. The surface properties of the covering – its hardness, surface energy, texture, and porosity – dictate how water is removed, how felt conditioning works, and how effectively the paper web transfers between sections. In the drying section, coverings need to withstand high temperatures while maintaining release properties to prevent sticking. Even in the forming and finishing sections, roll coverings impact web formation, surface smoothness, and overall sheet quality. A poorly performing or damaged roll cover can lead to web breaks, uneven profiles, increased energy use, and compromised paper quality, all of which translate directly into significant production losses. Therefore, optimizing “roll coverings for demanding papermaking applications” is a direct pathway to improving overall mill efficiency and product quality. Have you ever wondered just how much a microscopic surface variation on a roll can impact the feel and strength of the paper you hold in your hands?

Specific Challenges Requiring Innovative Solutions

Digging a bit deeper into the specifics, the “demanding” aspect isn’t just about pressure and temperature. It involves combating phenomena like chemical attack, deposit buildup, and crown maintenance under varying load conditions. For example, in alkaline papermaking environments increasingly common today, conventional rubber coverings can be prone to swelling and degradation. Deposit buildup, whether from stickies, fillers, or other process contaminants, can necessitate frequent cleaning downtime and impact roll performance. Maintaining a consistent nip profile across the width of wide paper machines, even with varying loads and thermal expansion, is another significant challenge. This is where the need for “innovative roll coverings” truly shines. Materials like advanced polyurethanes, specialized composites, and ceramics, often applied using sophisticated techniques, offer properties – such as enhanced chemical resistance, superior non-stick characteristics, improved thermal stability, and dynamic hardness capabilities – that were simply not possible with older rubber formulations. Addressing these specific pain points is central to the value proposition of cutting-edge covering technologies.

Defining “Innovative” in Modern Roll Covering Technology

What does “innovative” truly mean when we talk about roll coverings for “demanding papermaking applications”? It’s more than just a buzzword. It signifies a leap forward in material science, application techniques, and understanding of process dynamics. Innovation might involve developing new polymer formulations with tailored properties like exceptional abrasion resistance combined with high release characteristics. It could be pioneering composite structures that offer unparalleled strength and stiffness while remaining lightweight. Sometimes, innovation is in the application method itself, such as thermal spraying or advanced bonding techniques, ensuring perfect adhesion and uniform thickness. Interestingly enough, “innovative” also extends to predictive maintenance capabilities and surface modifications that allow for easier cleaning or reduced energy consumption. It’s about moving beyond incremental improvements to creating solutions that fundamentally change what’s possible in the mill, allowing machines to run faster, cleaner, and more reliably under conditions that previously caused frequent issues. True innovation solves problems that the industry thought were inherent and unavoidable.

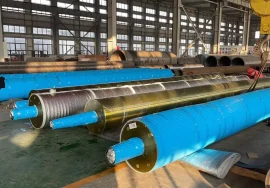

Advanced Materials Driving Performance

The bedrock of “innovative roll coverings” is often found in advanced materials. Modern polymers, particularly certain families of polyurethanes, offer wear resistance, chemical stability, and hardness profiles that were unattainable with traditional natural or synthetic rubbers. Ceramic composite coverings provide extreme hardness and durability, ideal for highly abrasive positions. Elastomers with specific fillers can be engineered for improved thermal conductivity, helping manage heat buildup. Furthermore, layering techniques, combining different materials to leverage their unique properties, allow for multi-functional coverings. For example, a covering might have a tough, wear-resistant outer layer bonded to a resilient, energy-absorbing core. Franky speaking, the material options available today are vast and complex, requiring deep expertise to select and apply the right one for a specific roll position and its unique operational stresses. Our company has invested heavily in researching and utilizing these cutting-edge materials to meet the evolving needs of papermakers facing ever more “demanding applications.”

Implementing Innovative Roll Coverings for Enhanced Mill Efficiency

The practical application of “innovative roll coverings” directly translates into tangible improvements in mill efficiency and profitability for “demanding papermaking applications.” By selecting the optimal covering for a specific position – be it a press roll, couch roll, or calender roll – mills can achieve higher dewatering rates, leading to significant energy savings in drying. Reduced sticking and deposit buildup minimize the need for wash-ups and manual cleaning, thereby increasing uptime. Enhanced durability means longer run times between maintenance shutdowns for roll grinding or recovering, lowering maintenance costs. Improved surface uniformity and stability contribute to better sheet quality, reducing rejects and improving customer satisfaction. In my experience, proactive mill managers understand that while an innovative covering might have a higher initial cost than a conventional one, the total cost of ownership, factoring in reduced energy, maintenance, and downtime, is often dramatically lower. It’s an investment that pays dividends quickly in demanding environments.

Case Studies and Real-World Impact

Let’s consider a hypothetical, but common, scenario in “demanding papermaking applications.” Imagine a press section roll struggling with persistent deposit buildup from secondary fibers, requiring weekly washing cycles that cost hours of production time. An “innovative roll covering” specifically engineered with ultra-low surface energy and excellent release properties could potentially extend that cleaning interval to months. This not only saves significant production time but also reduces the labor and chemicals associated with cleaning. Or think about a hard nip calender roll operating at high temperatures. A covering with superior thermal resistance and dynamic modulus control could maintain a consistent nip profile at operating temperatures, leading to improved calendering effect and reduced sheet variation. Many experts agree that these kinds of targeted innovations, based on a deep understanding of the process challenge, are where the real value of advanced roll coverings lies. They aren’t one-size-fits-all solutions, but rather tailored answers to specific operational headaches experienced in the mill.

Future Trends and the Evolution of Roll Coverings

Looking ahead, the evolution of “innovative roll coverings for demanding papermaking applications” is likely to continue apace. As papermakers push for faster machine speeds, lighter basis weights, and wider widths, the demands on rolls will only increase. Furthermore, the increasing use of recycled fibers and functional additives introduces new chemical and physical challenges that will require even more specialized covering properties. We can anticipate further advancements in materials science, potentially incorporating nanotechnology or smart materials that can adapt to changing conditions. There will also be a greater emphasis on sustainability, with coverings designed for longer life cycles, easier repairability, or even made from more environmentally friendly components. The focus will remain on delivering reliability and performance under pressure. What advancements do you foresee being most impactful in the next five to ten years for tackling the challenges in your specific papermaking application?

In summary, the relentless pressures and complex chemistry of modern “papermaking applications” necessitate continuous advancements in roll covering technology. From resisting chemical attack and abrasion to maintaining consistent nip profiles and improving dewatering efficiency, “innovative roll coverings” are indispensable tools for maximizing uptime, reducing costs, and enhancing product quality. By leveraging cutting-edge materials and sophisticated application techniques, these coverings provide tailored solutions to the industry’s most “demanding” challenges. Our company is dedicated to developing and supplying these high-performance coverings, working closely with papermakers to understand their specific needs and deliver solutions that drive real operational improvements. The journey of innovation in this critical area is far from over, promising even greater efficiency and performance for the paper industry in the years to come.

For more detailed information, please visit our official website: Innovative Roll Coverings for Demanding Papermaking Applications