Paper mill rolls are the unsung heroes of the paper manufacturing industry. These massive, precision-engineered cylinders are fundamental to virtually every stage of the paper-making process, from forming the initial sheet to imparting the final finish. Understanding the different types of paper mill rolls, their construction materials, critical maintenance routines, and proper selection criteria is paramount for any paper mill aiming for high-quality output, operational efficiency, and reduced downtime.

This comprehensive guide delves into the world of paper mill rolls, providing valuable insights for engineers, maintenance crews, and procurement specialists alike.

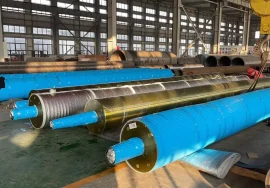

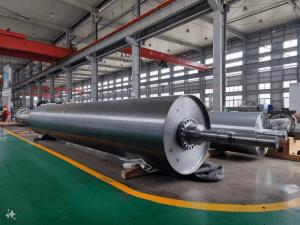

Overview shot of a paper machine highlighting various rolls

Understanding the Critical Role of Paper Mill Rolls

At its core, a paper machine is a complex system of interacting rolls. Each roll, or series of rolls, performs specific tasks: transporting the paper web, dewatering, pressing, drying, calendering, and reeling. The performance, condition, and precision of these rolls directly impact:

- Paper Quality: Affecting properties like smoothness, thickness, strength, and printability.

- Machine Efficiency: Influencing runnability, speed, and energy consumption.

- Operational Costs: Impacting maintenance expenses, roll lifespan, and unscheduled downtime.

Key Types of Paper Mill Rolls and Their Functions

Paper machines utilize a diverse array of rolls, each designed for a specific purpose within the paper-making journey. Here are some of the most critical types:

Forming Rolls / Headbox Rolls

Located in the “wet end” of the paper machine, these rolls, including breast rolls and forming board rolls, are crucial in the initial sheet formation process, supporting the forming fabric and aiding in early water removal from the pulp slurry.

Press Rolls

Press rolls are designed to mechanically remove water from the paper sheet by pressing it between two rolls under high pressure (nip pressure). This significantly reduces the moisture content before the sheet enters the dryer section. Common types include:

- Suction Press Rolls: Feature a perforated shell with an internal suction box to draw water out.

- Blind Drilled Press Rolls: Have numerous small, non-through holes for water collection.

- Grooved Press Rolls: Incorporate grooves on the roll surface to channel water away.

Diagram showing different types of press roll nips

Dryer Rolls (Dryer Cans)

These are large, steam-heated cylinders that dry the paper sheet through evaporation after it leaves the press section. Their surface temperature and heat transfer efficiency are critical for effective drying.

Calender Rolls

Used to improve the paper’s surface properties, such as smoothness and gloss. Calender stacks consist of several rolls (often a combination of hard and soft rolls) that create nips to compress and polish the paper sheet.

- Machine Calenders: Typically located at the end of the dryer section.

- Supercalenders: Offline units used for producing very smooth and high-gloss papers.

Reel Spools / Pope Reels

At the very end of the machine, the reel spool (or pope reel) winds the finished paper into large parent rolls (jumbos) for further processing or converting.

Guide Rolls & Spreader Rolls

Guide rolls ensure the proper tracking and alignment of the paper web and machine fabrics (wires, felts) as they travel through the machine. Spreader rolls (e.g., bowed rolls) help to prevent wrinkles and keep the sheet flat.

Essential Materials Used in Paper Mill Roll Construction

The choice of material for a paper mill roll depends on its application, the operating environment, and desired performance characteristics.

Metals

- Steel & Cast Iron (Chilled Iron): Common for roll bodies due to strength and machinability. Chilled iron provides a hard, wear-resistant surface.

- Stainless Steel: Used where corrosion resistance is paramount, such as in certain wet end applications.

Granite

Traditionally used for some press rolls due to its excellent water release properties, wear resistance, and ability to maintain a smooth surface.

Composite Materials

Increasingly popular for their lightweight, high strength-to-weight ratio, and corrosion resistance. Carbon fiber composites are a prime example.

Roll Covers

Many paper mill rolls are covered with specialized materials to enhance their performance:

- Rubber: Offers a range of hardness and chemical resistance, widely used for press rolls.

- Polyurethane: Known for excellent abrasion resistance, toughness, and load-bearing capacity. Often a preferred choice for demanding press and size press applications.

- Ceramic Coatings: Provide extreme hardness, wear resistance, and corrosion protection. Used on guide rolls, dryer rolls, and others.

- Tungsten Carbide Coatings: Offer superior wear resistance, especially in abrasive conditions.

Critical Aspects of Paper Mill Roll Maintenance

Proactive and meticulous maintenance is key to extending the life of paper mill rolls and ensuring consistent paper quality.

Regular Inspection & Cleaning

Frequent visual inspections for wear, damage, corrosion, and proper doctor blade operation. Regular cleaning prevents build-up of contaminants.

Grinding & Regrinding

Rolls wear over time, losing their precise profile and surface finish. Grinding restores the correct crown, concentricity, and surface quality. The frequency depends on the roll type, cover material, and operating conditions.

Roll Balancing

Essential for high-speed operations to prevent vibration, which can damage bearings, machine components, and affect paper quality. Balancing should be checked after grinding or cover replacement.

Bearing Maintenance

Proper lubrication, alignment, and regular checks of roll bearings are crucial to prevent premature failure.

Cover Repair & Replacement

Damaged roll covers can lead to paper defects. Minor repairs might be possible, but eventually, covers will need to be stripped and replaced.

Common Problems and Troubleshooting for Paper Mill Rolls

- Uneven Wear: Can be caused by misalignment, incorrect crowning, or issues with doctor blades.

- Corrosion: A significant issue, especially in the wet end or with aggressive chemical usage. Proper material selection and protective coatings are vital.

- Barring or Vibration Issues: Often linked to imbalance, bearing problems, incorrect roll profiles, or issues with connected equipment.

- Cover Delamination or Damage: Can result from mechanical impact, chemical attack, or excessive heat.

- Sheet Defects: Many paper quality issues (e.g., streaks, blotches, uneven profile) can be traced back to roll problems.

Selecting the Right Paper Mill Rolls for Optimal Performance

Choosing the appropriate roll involves considering several factors:

- Position in the Paper Machine: Determines the primary function and operating environment.

- Paper Grades to be Produced: Different grades require different roll surface properties and nip conditions.

- Machine Speed and Width: Higher speeds and wider machines place greater demands on roll construction and balancing.

- Required Nip Loading and Pressure: Critical for press and calender sections.

- Chemical Environment: Dictates material and cover selection for corrosion resistance.

- Temperature Range: Especially important for dryer rolls and rolls in high-friction applications.

- Budget and Total Cost of Ownership (TCO): Balancing initial investment with expected lifespan, maintenance costs, and performance.

Conclusion

Paper mill rolls are sophisticated and indispensable components in the paper-making process. Their proper design, material selection, precise manufacturing, and diligent maintenance are fundamental to producing high-quality paper efficiently and cost-effectively. By understanding the intricacies of these critical assets, paper mills can optimize their operations, minimize downtime, and maintain a competitive edge in the market.