Introduction

Paper machine rollers are the backbone of modern papermaking, driving efficiency, quality, and reliability across every stage of production. From the forming section to the finishing line, these precision-engineered components handle critical tasks such as dewatering, web consolidation, and surface enhancement. As paper machines evolve to meet demands for higher speeds, sustainability, and specialized paper grades, selecting the right rollers and maintaining them effectively is paramount. This in-depth guide explores the types, materials, applications, maintenance strategies, emerging trends, and practical solutions for paper machine rollers, providing actionable insights for engineers, procurement managers, and industry professionals aiming to optimize their paper production lines.

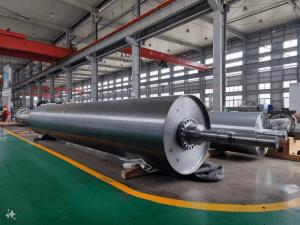

Overview shot of a paper machine highlighting various rolls

The Critical Role of Paper Machine Rollers

Paper machine rollers, often interchangeably called paper mill rolls, are cylindrical components integral to the forming, press, drying, and calendering sections of a paper machine. Each roller type is designed for specific functions, such as removing water from the pulp slurry, pressing the paper web, or improving surface properties for printing or packaging applications. With modern paper machines operating at speeds exceeding 2200 meters per minute and producing diverse grades like tissue, newsprint, and heavy-duty board, rollers directly impact key metrics: dewatering efficiency, paper strength, surface smoothness, and machine uptime.

For example, advanced suction press rollers with vacuum systems can achieve up to 50% dry content in the press section, reducing energy consumption in the drying stage by 10-15%. Similarly, calender rollers with deflection-compensated designs ensure uniform nip pressure, critical for high-quality coated papers. The right roller selection and maintenance strategy can reduce downtime by up to 30% and extend component life by years, making them a cornerstone of cost-effective production.

Types of Paper Machine Rollers and Their Functions

1. Suction Press Rollers

Suction press rollers are essential in the press section, using vacuum technology to extract water from the wet paper web. These rollers feature perforated shells, typically made of duplex stainless steel, with precision-engineered hole patterns to maximize dewatering efficiency.

-

Key Features:

-

Support high-speed operations (up to 2200 m/min).

-

Available with rubber, polyurethane, or ceramic coatings for enhanced durability.

-

Ideal for lightweight papers like tissue and newsprint.

-

-

Case Study: A North American tissue mill adopted Voith’s suction press rollers, achieving a 25% increase in dewatering efficiency and reducing press felt replacement frequency by 15%.

2. Plain Press Rollers

Plain press rollers complement suction rollers by applying mechanical pressure to consolidate the paper web and enhance dewatering. They are often paired with high-permeability press felts to optimize water removal and extend felt life.

-

Key Features:

-

Upper rollers use granite or synthetic stone for a smooth, durable surface.

-

Lower rollers feature rubber-coated cast iron or polyurethane for flexibility and wear resistance.

-

Handle nip pressures up to 1000 kN/m in high-pressure configurations.

-

-

Application Note: Widely used in kraft paper and linerboard production, where consistent web consolidation is critical.

3. Calender Rollers

Calender rollers enhance paper surface properties like gloss, smoothness, and printability in the finishing section. Operating under high pressure (up to 300 kN/m) and temperature (up to 200°C), these rollers require robust materials and precise engineering.

-

Key Features:

-

Deflection-compensated designs ensure uniform nip pressure across wide machines (up to 12 meters).

-

Soft calender rollers with heated polymer coatings deliver superior gloss for coated papers.

-

Essential for specialty grades like photographic paper and high-quality printing papers.

-

-

Trend: Multi-nip calender systems are gaining popularity for achieving ultra-smooth surfaces without compromising paper bulk.

4. Shoe Press Rollers

Shoe press rollers represent a cutting-edge innovation in the press section, featuring extended nip zones (up to 300 mm wide) that increase dewatering efficiency by 4-6% compared to traditional press rollers. These rollers use a flexible belt or “shoe” to apply uniform pressure over a larger area, reducing energy consumption and improving paper strength.

-

Key Features:

-

Support ultra-high-speed machines (>2000 m/min).

-

Polyurethane or composite belts enhance durability under high loads.

-

Ideal for packaging papers and high-strength board grades.

-

-

Case Study: A Chinese board mill implemented Andritz’s shoe press rollers, reducing drying energy costs by 12% and increasing production speed by 10%.

5. Breast Rollers

Breast rollers, located in the forming section, guide the pulp slurry onto the forming fabric, ensuring uniform sheet formation. Modern designs incorporate grooved or drilled surfaces to enhance drainage and formation quality.

-

Key Features:

-

Made of stainless steel or bronze for corrosion resistance.

-

Grooved breast rollers improve drainage by up to 20% compared to smooth rollers.

-

Critical for high-speed machines producing thin papers like newsprint.

-

6. Dryer Rollers

Dryer rollers, found in the drying section, use steam heating to evaporate residual moisture from the paper web. These rollers are typically made of cast iron or steel to withstand temperatures up to 350°C.

-

Key Features:

-

Large diameters (up to 2 meters) ensure efficient heat transfer.

-

Chrome or polymer coatings reduce sticking and improve release properties.

-

Essential for energy-efficient drying in high-volume production.

-

7. Guide and Tension Rollers

Guide and tension rollers maintain proper web alignment and tension, preventing wrinkles and breaks. These rollers are often lightweight and coated with low-friction materials to minimize wear.

-

Key Features:

-

Precision-balanced to reduce vibration at high speeds.

-

Ceramic or composite coatings extend service life by up to 40%.

-

Critical for wide machines to ensure stable web handling.

-

Material Selection for Optimal Performance

The choice of materials for paper machine rollers is critical for balancing performance, durability, and cost. Common materials include:

-

Duplex Stainless Steel: Preferred for suction and shoe press rollers due to its corrosion resistance and ability to maintain precise hole patterns. Valmet’s suction roll shells, for example, can withstand over 10 years of continuous operation.

-

Rubber and Polyurethane Covers: Used in press rollers to enhance grip and reduce wear on press felts. HEXPOL’s advanced rubber compounds offer up to 30% longer service life compared to standard rubber.

-

Granite or Synthetic Stone: Ideal for plain press rollers in low-speed applications due to their smooth, non-deformable surfaces.

-

Chilled Cast Iron: Common in calender and dryer rollers for its thermal stability and resistance to mechanical stress.

-

Ceramic and Polymer Composites: Emerging as lightweight, chemical-resistant options for high-speed and abrasive environments. Ceramic-coated rollers reduce wear by 40% in high-abrasion settings.

When selecting materials, consider paper type, machine speed, and environmental conditions. For instance, polyurethane-coated suction rollers are ideal for high-speed tissue production, while granite rollers suit slower, heavy-duty board production.

Maintenance Strategies for Longevity and Efficiency

Effective maintenance of paper machine rollers minimizes downtime, extends service life, and ensures consistent paper quality. Key strategies include:

-

Routine Inspections: Check for surface wear, cracks, and hole blockages in suction rollers. Blocked holes can reduce dewatering efficiency by up to 15%.

-

Cleaning and Lubrication:

-

Wet end rollers: Use water-resistant grease to protect bearings from moisture ingress.

-

Dry end rollers: Employ oil circulation systems to manage high temperatures (up to 350°C).

-

-

Surface Regrinding: Regrind roller surfaces every 6-12 months to restore smoothness and remove wear patterns. For rubber-covered rollers, regrinding can extend life by 20-30%.

-

Dynamic Balancing: Ensure rollers are balanced to prevent vibration, which can cause web breaks at speeds above 1500 m/min.

-

OEM Parts and Alignment: Use original equipment manufacturer parts to avoid misalignment. Laser alignment systems can reduce web breaks by 15%.

-

Predictive Maintenance: Install IoT sensors to monitor vibration, temperature, and load in real-time. Andritz’s smart rollers reduced unplanned downtime by 25% in a recent trial.

Pro Tip: Use thermal imaging to detect hot spots on dryer rollers, enabling early intervention to prevent bearing failures.

Troubleshooting Common Roller Issues

Paper mills face challenges like wear, misalignment, and high maintenance costs. Solutions include:

-

Surface Wear: Apply ceramic or polyurethane coatings to extend roller life in abrasive conditions. For example, ceramic coatings reduce wear by 40% in high-speed tissue production.

-

Misalignment: Use laser alignment systems to ensure precision, reducing web breaks by 15%.

-

Vibration: Perform dynamic balancing every 6 months to minimize vibration-induced defects, especially in calender rollers.

-

Cost Control: Opt for modular roller designs that allow partial repairs, saving up to 30% in maintenance costs.

Case Study: A Southeast Asian paper mill resolved chronic web breaks by upgrading to Valmet’s deflection-compensated calender rollers, improving uptime by 20% and reducing maintenance costs by 10%.

Industry Trends and Innovations

The paper machine roller industry is evolving to meet demands for efficiency, sustainability, and customization. Key trends include:

-

Shoe Press Technology: Shoe press rollers with extended nip zones (up to 300 mm) increase dry content by 4-6%, reducing drying energy costs by 10-12%. Andritz’s systems are leading this shift in board production.

-

Eco-Friendly Materials: Recyclable polyurethane covers and low-energy coatings align with sustainability goals. HEXPOL’s green compounds reduce carbon footprints by 15%.

-

Smart Rollers: IoT-enabled rollers provide real-time data on wear, alignment, and temperature, enabling predictive maintenance. A European mill reported a 20% reduction in maintenance costs with smart rollers.

-

Customized Designs: Suppliers like Qinyang Aotian offer rollers up to 12 meters long and 100 tons in weight, tailored for specific paper machines.

-

Hybrid Coatings: Ceramic-polymer hybrids combine durability and flexibility, extending roller life by up to 50% in abrasive environments.

Choosing the Right Paper Machine Rollers

Selecting optimal rollers involves balancing technical requirements, operational goals, and budget constraints:

-

Paper Grade: Tissue and newsprint require high-permeability felts and suction rollers, while board production demands heavy-duty press rollers.

-

Machine Speed: High-speed machines (>1800 m/min) need deflection-compensated rollers with durable coatings.

-

Cost vs. ROI: Polyurethane-coated rollers reduce felt replacement costs by 20% over five years.

-

Supplier Expertise: Partner with suppliers offering rapid-response aftermarket services and customization. Local suppliers in China provide 24/7 technical support.

Case Study: A Scandinavian mill upgraded to Valmet’s grooved breast rollers, achieving a 22% improvement in sheet formation and a 12% reduction in energy costs.

Frequently Asked Questions (FAQ)

-

What is the difference between suction and plain press rollers?

-

Suction press rollers use vacuum systems to remove water, ideal for lightweight papers. Plain press rollers rely on mechanical pressure, suitable for heavier grades like board.

-

-

How often should rollers be reground?

-

Rubber-covered rollers typically require regrinding every 6-12 months, depending on machine speed and paper type.

-

-

What are the benefits of shoe press rollers?

-

Shoe press rollers increase dewatering efficiency by 4-6%, reduce energy costs, and improve paper strength, especially for packaging grades.

-

-

How can I reduce roller maintenance costs?

-

Use predictive maintenance with IoT sensors, opt for modular designs, and apply durable coatings like polyurethane or ceramic.

-

Conclusion

Paper machine rollers are vital to achieving high-efficiency, high-quality paper production. By selecting the right roller types, materials, and maintenance strategies, paper mills can enhance performance, reduce costs, and stay competitive in a dynamic industry. From suction press rollers for tissue production to innovative shoe press rollers for energy savings, the right rollers are an investment in long-term success.

For industry-leading paper machine rollers and tailored solutions for your paper machine, visit our website to discover our comprehensive range of products and services.