The world of paper manufacturing is one that constantly seeks perfection. At its heart lies the paper machine, a marvel of modern engineering. But within this complex system, specific components play an outsized role in determining both the quality of the final product and the efficiency of the entire operation. Frankly speaking, few components are as critical in this regard as the rolls. From the forming section to the press, dryer, and calendar sections, paper machine rolls perform diverse functions, each demanding incredibly tight tolerances and meticulous design. This is where the concept of precision engineering becomes not just important, but absolutely non-negotiable. Without unparalleled precision in these cylindrical workhorses, achieving consistent, high-quality paper and maintaining efficient machine performance simply isn’t possible. We’re talking about engineering that accounts for dynamic loads, temperature variations, material stresses, and incredibly fine surface requirements – a complex symphony of physics and mechanics that directly impacts everything from sheet uniformity and strength to energy consumption and downtime. It’s a cornerstone of competitive paper production. Have you ever considered just how much rides on the perfect rotation and surface of a massive paper machine roll moving at high speeds?

The Foundation: Defining Precision Engineering in Paper Machine Rolls

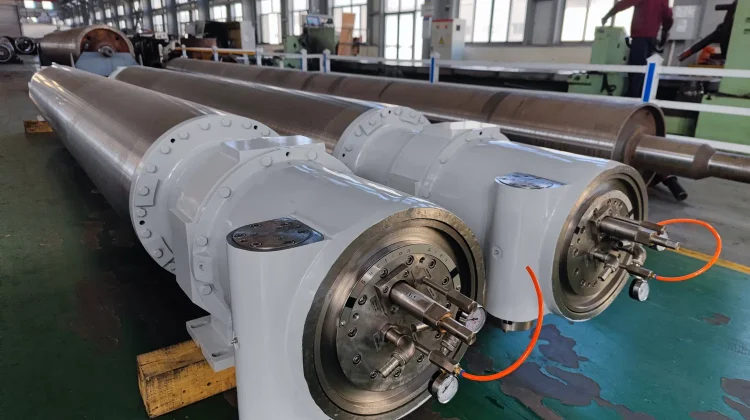

So, what exactly do we mean by precision engineering when applied to paper machine rolls? It’s far more than just manufacturing something with tight dimensions. Precision in this context encompasses a holistic approach to design, material selection, manufacturing processes, and quality control, all aimed at ensuring the roll performs its specific function flawlessly under demanding operational conditions. Consider a press roll, for example. Its shape, crown profile, surface hardness, and dynamic balance must be engineered with extreme accuracy. Even minor deviations – fractions of a millimeter in diameter or microscopic imperfections on the surface – can lead to uneven pressure distribution, affecting moisture removal and causing variations in the paper sheet’s caliper and density. Similarly, dryer rolls need precise surface finishes and internal steam flow channels to ensure uniform heat transfer, preventing moisture spots or uneven drying that compromises sheet quality. This level of engineering requires specialized equipment, advanced measurement tools, and highly skilled technicians. It involves selecting materials that can withstand corrosive chemicals, high temperatures, and immense mechanical stresses while maintaining dimensional stability. It’s about predicting and mitigating issues like thermal expansion, vibration, and wear before the roll is even installed. In our experience, achieving this level of precision is the differentiator between rolls that merely function and rolls that actively contribute to superior output and machine longevity.

Critical Aspects of Roll Manufacturing Precision

Delving deeper into the manufacturing side, several critical aspects embody precision engineering for paper machine rolls. Firstly, dimensional accuracy is paramount. This includes not only the overall diameter and length but also critical features like bearing journals, internal bores, and any functional surfaces like grooves or patterns. Tolerances are often measured in microns, demanding sophisticated machining and grinding capabilities. Secondly, geometric precision, such as straightness, roundness, and concentricity, is vital for smooth operation and even contact across the roll width. A roll that isn’t perfectly round or straight will introduce uneven nips or inconsistent drying, directly degrading sheet quality. Thirdly, surface finish is a key factor, varying significantly depending on the roll’s function. From highly polished surfaces on calendar rolls to specific roughness profiles on press rolls, the surface texture influences everything from web release and heat transfer to sheet finish and felt conditioning. Achieving and maintaining the correct surface finish requires specialized grinding and surfacing techniques. Fourthly, dynamic balancing is absolutely crucial, especially for rolls operating at high speeds. An unbalanced roll can cause significant vibration, leading to machine damage, premature bearing wear, and variations in the sheet that manifest as barring or non-uniformity. Precision balancing minimizes these harmful vibrations, ensuring stable and efficient operation. To be honest, neglecting any of these aspects compromises the roll’s ability to contribute positively to the paper-making process.

Enhancing Sheet Quality Through Roll Precision

The direct link between the precision of paper machine rolls and the quality of the paper sheet produced cannot be overstated. Every roll in the machine line contributes in some way to the final sheet properties, and any lack of precision is quickly reflected in the product. Think about the forming section rolls; their precise design and surface characteristics influence how the fiber slurry dewaters and forms the initial web, impacting basis weight uniformity and formation. In the press section, precisely crowned and surfaced rolls ensure uniform moisture removal across the sheet width, reducing moisture profile variations that can cause curling, cockling, or uneven drying later on. A non-precise press roll can lead to wet streaks or dry streaks, significantly degrading the final sheet’s printability and strength. Dryer cans, with their precisely machined surfaces and internal steam flow, are responsible for uniform heat transfer. Poor surface contact or uneven internal heating due to lack of precision can result in uneven drying, leading to brittle spots or areas prone to web breaks. Calendar rolls, arguably the rolls where surface precision is most visually evident, determine the final smoothness, gloss, and caliper of the paper. Any surface defect or crowning error on a calendar roll is directly imprinted onto the paper surface, ruining its aesthetic and functional properties. Interestingly enough, even seemingly simple guide rolls or felt rolls require precision alignment and balance to ensure the web and felts track correctly and smoothly, preventing wrinkles, creases, or tearing that would scrap material. Therefore, precision engineering isn’t just about making a good roll; it’s about crafting a tool that actively improves the paper product’s consistency and quality attributes.

Specific Quality Parameters Influenced by Roll Precision

Let’s get more specific about the sheet quality parameters that precision engineering in paper machine rolls directly influences. One of the most fundamental is **basis weight uniformity**. Precisely designed and maintained forming rolls and press nips help ensure the fiber and water distribution is even, leading to a consistent weight per unit area across the sheet. **Caliper (thickness) consistency** is another critical factor, heavily reliant on the precision of press and calendar rolls. Uniform pressure application across the web width is essential for achieving consistent densification and thickness. **Moisture profile** uniformity, as mentioned, is profoundly affected by the precision of press and dryer rolls; uneven moisture can cause significant issues downstream. **Surface properties** like smoothness, gloss, and printability are direct outcomes of the precision and surface finish of calendar and coating rolls. Any imperfections, like chatter marks or roll grinding patterns not removed during finishing, will negatively impact these characteristics. Furthermore, roll precision contributes to minimizing defects such as **wrinkles, creases, barring**, and **web breaks**, which are often caused by roll vibration, misalignment, or surface issues stemming from a lack of engineering precision. In essence, every single quality metric a paper mill strives for is, in part, a testament to the precision embedded in its paper machine rolls. Poor roll precision creates problems the paper can’t recover from.

Driving Operational Efficiency Through Precise Rolls

Beyond sheet quality, precision engineering in paper machine rolls is a significant driver of operational efficiency. How so? Primarily by ensuring smoother machine operation, reducing downtime, minimizing waste, and optimizing energy consumption. Rolls that are precisely manufactured, balanced, and aligned run more smoothly, reducing vibration throughout the machine frame. Vibration is an enemy of efficiency; it causes premature wear on bearings, seals, and other components, leading to unexpected failures and costly, unscheduled downtime. A precisely engineered roll also maintains its performance characteristics over a longer lifespan. For instance, a press roll with a precise crown profile will maintain uniform pressure longer than one with manufacturing variations, delaying the need for regrinding or replacement. This extends the run time between maintenance stops, directly boosting operational uptime. Precision also plays a role in energy consumption. In the press section, optimal dewatering achieved through precise roll nips reduces the energy required for drying. In the dryer section, efficient heat transfer facilitated by precisely surfaced rolls minimizes the steam needed. In the calendar section, precise control over nip pressure and temperature allows for achieving desired sheet properties with minimal passes and less energy input. Frankly speaking, investing in precision engineered rolls pays dividends not just in quality, but in the bottom line through reduced operational costs and increased throughput. It allows the machine to run faster, longer, and more reliably.

Operational Benefits Beyond Uptime and Energy

Let’s explore some further operational benefits derived from the meticulous precision of paper machine rolls. Reduced web breaks are a major one. Many breaks are initiated by issues related to rolls, such as poor alignment, uneven nip pressure, surface damage, or vibration from imbalance. Precisely engineered rolls minimize these risk factors, leading to fewer breaks, higher machine speeds, and significantly less wasted product and time associated with threading and cleaning up after a break. This directly impacts throughput. Extended component lifespan is another key benefit. Precision in bearing fits, roll balancing, and surface hardness means bearings last longer, seals remain effective, and the roll body itself experiences less stress and wear. This reduces maintenance frequency and the cost of replacement parts. Furthermore, precise rolls often require less frequent maintenance, such as regrinding or resurfacing, which further contributes to higher machine availability. The ability to run the machine at designed speeds, or even push limits, is also facilitated by the confidence that comes from knowing the rolls are operating within tight tolerances and performing reliably. I’ve found that mills prioritizing roll precision experience fewer unexpected operational headaches and have more predictable production schedules. This level of reliability is invaluable in a competitive manufacturing environment. Ultimately, operational efficiency is the cumulative effect of countless small improvements, and precision in every roll contributes significantly to that overall gain.

Challenges and Solutions in Achieving Roll Precision

Achieving and maintaining the necessary precision in paper machine rolls is not without its challenges. These rolls are massive, sometimes weighing several tons, and operate under harsh conditions involving heat, moisture, chemicals, and immense physical forces. Manufacturing these giants to micron tolerances requires specialized facilities and expertise. One significant challenge is managing thermal expansion; rolls heat up during operation, and this expansion must be accounted for in the design and crowning. Another is wear and tear; the demanding environment causes surfaces to degrade and profiles to change over time, necessitating maintenance like grinding. Preventing corrosion and buildup of sticky materials is also critical, as surface contamination compromises precision. Furthermore, maintaining precise alignment within the machine frame itself is crucial, as even a perfectly precise roll will perform poorly if misaligned. The solutions to these challenges lie in continuous innovation in materials science, manufacturing technology, and maintenance practices. Using advanced alloys or composite materials, employing state-of-the-art CNC grinding machines and robotic surfacing techniques, and implementing sophisticated condition monitoring systems are all part of the answer. Precision measurement tools, such as laser alignment systems and profilometers, are essential for verifying accuracy during manufacturing and assessing condition during operation. Our company focuses on providing solutions that address these very challenges, leveraging expertise in materials, machining, and surface technology to ensure rolls meet and maintain the required precision levels throughout their service life.

The Role of Maintenance and Monitoring in Sustaining Precision

It’s crucial to understand that precision engineering isn’t a one-time event during manufacturing; it’s a characteristic that must be maintained throughout the roll’s operational life. Even the most precisely manufactured roll will lose its critical attributes if not properly cared for. This highlights the indispensable role of diligent maintenance and advanced monitoring. Regular inspection for surface damage, wear, and signs of corrosion is fundamental. Timely regrinding or resurfacing is necessary to restore the roll’s critical profile and surface finish when wear exceeds acceptable tolerances. The frequency and method of regrinding must be precise themselves to avoid introducing new imperfections. Furthermore, monitoring operational parameters like roll temperature, vibration levels, and bearing temperatures can provide early warnings of developing issues that could compromise precision or lead to failure. Techniques such as thermal imaging and vibration analysis are powerful tools in this regard. Proper lubrication and seal maintenance are also vital for protecting the precision of bearing journals and internal components. Frankly speaking, a comprehensive maintenance program is the shield that protects the investment made in precision engineering. Without it, the benefits of initial precision will erode over time, negatively impacting both sheet quality and operational efficiency. It’s a continuous commitment, not just a manufacturing spec.

The Lifecycle Benefit: Sustaining Quality and Efficiency Long-Term

When you consider the entire lifecycle of a paper machine roll, the long-term benefits of prioritizing precision engineering become strikingly clear. A precisely engineered roll, properly maintained, offers a significantly lower total cost of ownership compared to a less precise alternative. While the initial investment in a high-precision roll might be higher, this is often offset by extended service life, reduced maintenance costs, lower energy consumption, and, crucially, consistently higher paper quality. The ability to produce a higher percentage of on-spec product with fewer rejects or downgrades directly impacts profitability. Furthermore, the reduced risk of unexpected failures stemming from imbalance or manufacturing defects means fewer costly emergency repairs and less lost production time. A reliable, precisely engineered roll contributes to a more stable and predictable production process, allowing mill operators to focus on optimizing other parameters rather than constantly troubleshooting roll-related issues. In my experience, mills that invest in precision engineering for their rolls see not just immediate improvements in sheet quality and efficiency but also sustain these gains over years of operation. It creates a virtuous cycle where reliable components enable better performance, leading to higher profitability and the ability to reinvest in maintaining that level of precision. It’s a strategic choice that impacts the mill’s competitiveness for the foreseeable future. Why settle for rolls that just “work” when you can have rolls that actively enhance your entire operation?

Precision as a Competitive Advantage

In today’s competitive paper market, small differences in quality and efficiency can translate into significant market advantage. This is where the sustained benefits of precision engineering in paper machine rolls truly shine as a competitive differentiator. Mills producing paper with more uniform basis weight, consistent caliper, better surface finish, and fewer defects are better positioned to meet demanding customer specifications and command potentially higher prices. Simultaneously, achieving this quality level with higher operational efficiency – meaning less waste, lower energy costs, and higher machine uptime – directly lowers production costs. This dual advantage of superior quality and lower cost is the holy grail in manufacturing, and precision rolls are a key enabler. Investing in components engineered to the highest standards allows a mill to push its machine to its performance limits while maintaining quality and reliability. It provides the operational stability needed to implement advanced control strategies and optimize processes further. It’s no exaggeration to say that precision in these fundamental components provides the bedrock upon which world-class paper manufacturing operations are built. It allows producers to be proactive in optimizing their process rather than reactive in fixing problems caused by imprecise equipment. Our commitment is to provide the precision engineered rolls and related services that empower paper manufacturers to achieve and maintain this crucial competitive advantage.

Precision engineering in paper machine rolls is unequivocally central to achieving both superior sheet quality and optimal operational efficiency. It touches every part of the paper-making process, from initial web formation to the final surface finish, and impacts key operational metrics like uptime, energy consumption, and maintenance costs. The challenges in achieving and sustaining this precision are real, but with the right approach to design, manufacturing, and ongoing maintenance, they are surmountable. The long-term benefits – consistent product quality, reduced waste, lower operating costs, and increased machine reliability – make the investment in precision engineering a clear strategic advantage. It’s about building quality and efficiency into the very fabric of the machine, roll by roll. As we’ve discussed, this level of detail matters immensely in a high-speed, high-volume manufacturing environment like a paper mill. It’s the difference between struggling to meet quality targets and consistently exceeding them, between battling frequent downtime and enjoying predictable, reliable production. Precision isn’t just a feature; it’s a performance enhancer and a cost reducer, fundamental to modern paper production success.

For more detailed information, please visit our official website: Precision Engineering in Paper Machine Rolls: Enhancing Sheet Quality & Operational Efficiency