Solving Common Paper Machine Roll Problems: A Quick Guide

Paper machines are complex beasts, isn’t that the truth? At the heart of their operation are the rolls – countless rolls performing crucial tasks from dewatering and pressing to drying and calendering. When these rolls aren’t performing optimally, the entire process suffers, leading to frustrating downtime, decreased product quality, and significant financial losses. Frankly speaking, keeping these rolls in top shape is non-negotiable for a profitable paper mill. But what are the most common issues you’re likely to encounter, and how can you get a handle on solving them quickly and effectively? That’s precisely what this guide aims to address, offering insights gleaned from years in the industry.

Understanding and Identifying Common Paper Machine Roll Problems

Diving straight into the core of the matter, let’s talk about the types of problems that frequently plague paper machine rolls. Surface wear is perhaps the most ubiquitous issue. Rolls are constantly subjected to immense pressure, heat, friction, and often corrosive substances. This leads to gradual abrasion, pitting, or scoring on the roll surface. You might notice uneven wear patterns, which can significantly impact sheet uniformity and dewatering efficiency. Another major concern is roll damage, ranging from minor dents and nicks caused by foreign objects passing through, to catastrophic failures like journal cracks or shell delamination. Identifying these issues early is paramount; a small surface imperfection today can escalate into a major problem tomorrow if left unchecked. It’s worth noting that while some problems are visually obvious, others, like subtle vibration or bearing issues, require more specialized diagnostic tools.

Beyond surface and structural damage, internal issues can also cause significant headaches. Bearing failures are a prime example. Roll bearings operate under extreme loads and conditions, and if lubrication is inadequate or contamination occurs, they can fail rapidly, leading to roll seizure, vibration, and potential damage to the roll body itself. Crown profile changes are another common problem, particularly with press and calender rolls. The crown is specifically designed to compensate for roll deflection under load, ensuring uniform nip pressure. However, wear, thermal expansion, or improper maintenance can alter this profile, resulting in uneven moisture profiles, caliper variations, and poor sheet quality. Have you ever wondered why seemingly identical rolls perform differently? Often, it boils down to subtle variations in crown or undetected surface issues. Addressing these specific problems requires a deep understanding of roll mechanics and materials.

Investigating the Root Causes of Paper Machine Roll Issues

Solving common paper machine roll problems isn’t just about fixing the symptom; it’s fundamentally about understanding and eliminating the root cause. Surface wear, for instance, isn’t just “wear.” It could be excessive pressure, abrasive fillers in the pulp, incorrect showering, or even improper roll cover material for the specific position and application. Roll damage might stem from operational errors, poor housekeeping leading to tramp metal in the sheet, or material fatigue if maintenance schedules are neglected. Bearing failures are almost always linked to lubrication issues (wrong type, insufficient supply, contamination) or misalignment. Interestingly enough, seemingly unrelated issues elsewhere in the machine can manifest as roll problems. Poor felt conditioning, for example, can increase load on press rolls and accelerate wear or impact dewatering performance.

Thermal factors play a huge role, particularly in dryer and calender sections. Uneven heating or cooling can cause thermal expansion differences, leading to stresses, cracking, or deformation of the roll body or cover. In press sections, process water chemistry can contribute to corrosion or deposit buildup on roll surfaces, affecting both nip pressure and dewatering. Many experts agree that simply replacing a damaged roll without investigating *why* it failed is a recipe for repeat failures. Root cause analysis, involving detailed inspection, operational data review, and sometimes material analysis, is critical. It’s the difference between a quick fix and a lasting solution. Identifying these underlying factors allows for targeted corrective actions that prevent the same problem from cropping up again shortly after repairs.

Effective Strategies for Solving Paper Machine Roll Problems

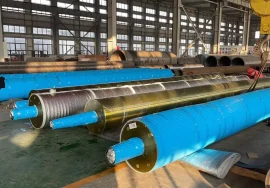

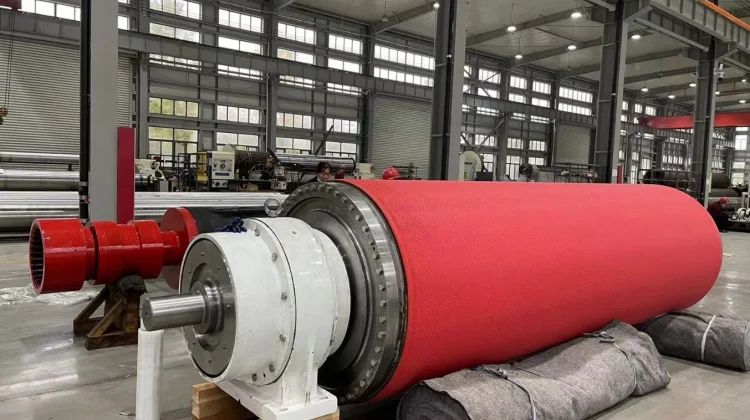

With common problems and their causes identified, the next step is implementing effective solutions. For surface wear and minor damage, regrinding is a standard and necessary procedure. This involves removing a small amount of material from the roll surface to restore its original profile and smoothness. The frequency of regrinding depends on the roll type, position, and operating conditions, but maintaining a regular schedule is vital to prevent excessive wear that could require much costlier repairs or early replacement. For rolls with specialized covers (like rubber, polyurethane, or composite), resurfacing or recovering is often required. Selecting the right cover material is crucial; it needs to withstand the specific thermal, chemical, and mechanical stresses of its position. Our company offers a range of specialized roll covers designed to enhance durability and performance in various machine sections, directly addressing common wear and damage issues.

Addressing bearing issues typically involves replacement, but the solution doesn’t stop there. It requires a thorough inspection of the bearing housing, lubrication system, and alignment. Upgrading to higher-capacity or sealed bearings, implementing advanced lubrication monitoring systems, and ensuring precise alignment during installation can significantly extend bearing life and prevent future failures. For crown profile problems, dynamic grinding or specialized measurement systems can ensure the roll is ground to the exact required profile. In some cases, thermal control systems or active crown control rolls are necessary to maintain the correct nip profile under varying operating conditions. Investing in modern monitoring technology, such as vibration analysis or thermal imaging, allows for proactive identification of potential problems before they lead to significant downtime, a key aspect of a quick guide approach to solving issues.

Preventative Maintenance: A Proactive Approach to Paper Machine Roll Issues

Perhaps the most effective way to solve common paper machine roll problems is to prevent them from happening in the first place. A robust preventative maintenance program is non-negotiable. This includes scheduled inspections, lubrication routes, and planned downtime for roll changes and regrinding. Regular inspection should cover visual checks for surface damage, signs of bearing issues (heat, noise, vibration), and proper alignment. Utilizing predictive maintenance technologies, like vibration analysis or oil analysis, can detect potential problems in their infancy, allowing for planned intervention rather than reactive emergency repairs. I’ve found that mills with strong preventative maintenance cultures experience significantly less unscheduled downtime related to roll failures.

Selecting the right roll materials and covers for each specific application is also a critical preventative measure. Not all roll covers are created equal, and choosing one that is resistant to the specific chemicals, temperatures, and abrasive forces in its position can dramatically extend roll life and reduce the frequency of issues. Ensuring correct machine setup, including proper alignment of rolls and related components (like doctor blades and showers), minimizes uneven wear and stress. Operator training is also vital; ensuring operators understand the impact of process changes on roll performance helps prevent problems caused by operational errors. To be honest, a small investment in training and preventative measures today can save millions in lost production and repair costs tomorrow. Our services include expert consultation to help optimize roll material selection and maintenance schedules.

The Impact of Technology on Solving Roll Problems Quickly

Modern technology has revolutionized our ability to quickly diagnose and solve paper machine roll problems. Advanced roll inspection equipment, such as laser scanners for profile and diameter measurement or eddy current testing for surface and subsurface defects, allows for detailed assessment without removing the roll from the machine in some cases, or during brief outages. Online vibration monitoring systems provide continuous data streams, alerting maintenance teams to potential bearing or balance issues long before they become critical. Thermal cameras can identify hot spots indicative of bearing problems or uneven thermal profiles.

Furthermore, data analytics platforms can process information from various sensors across the paper machine, identifying correlations and predicting potential roll failures based on historical data and operating conditions. This shift from reactive repair to predictive maintenance is a game-changer. It enables mills to schedule roll maintenance proactively during planned shutdowns, minimizing the impact on production. Frankly speaking, embracing these technologies is no longer optional for mills aiming for high efficiency and reliability; it’s essential for truly solving common roll problems quickly and effectively. We utilize cutting-edge technology in our diagnostic services to provide accurate assessments of roll condition.

Addressing Specific Types of Common Roll Problems in Detail

Let’s delve slightly deeper into a few specific common problems. Crowning issues, as mentioned, are prevalent. Incorrect or worn crowns lead to uneven nip pressure. In press sections, this means uneven dewatering, resulting in moisture streaks in the sheet. In calenders, it causes variations in caliper and smoothness. The solution isn’t just regrinding; it’s ensuring the regrinding is done to the exact, calculated dynamic crown profile required for the typical operating loads. Another specific problem is roll barring or chatter, which creates caliper variations and sometimes even visual defects in the sheet. This can be caused by various factors including vibration, bearing issues, or resonant frequencies in the machine frame. Diagnosing barring often requires specialized vibration analysis equipment to pinpoint the source.

Corrosion and deposit buildup are particularly problematic in wet sections. Process water chemistry, pH levels, and the presence of aggressive chemicals or microorganisms can lead to pitting and scaling on roll surfaces and inside roll bodies. This not only damages the roll but can also negatively impact dewatering and sheet release. Solutions involve water treatment programs, selecting corrosion-resistant roll materials or coatings, and effective cleaning procedures. Seal failures are another specific issue, especially on rolls requiring internal showering or cooling. Failed seals lead to water leakage, which can damage bearings and cause roll imbalance. Regular inspection and timely replacement of seals are crucial here. Understanding these specific manifestations of general “roll problems” is key to applying the correct corrective and preventative measures.

Conclusion: A Quick Wrap-up on Solving Paper Machine Roll Problems

So, what’s the takeaway from this quick guide to solving common paper machine roll problems? It boils down to a few key principles: proactive identification through regular inspection and monitoring, understanding the root cause behind every failure, implementing appropriate corrective actions like regrinding, resurfacing, or part replacement, and crucially, focusing on preventative maintenance and technology to avoid future issues. Paper machine rolls are vital, and their reliability directly impacts your mill’s productivity and product quality. Ignoring minor issues is a costly gamble.

By staying vigilant, leveraging diagnostic tools, and maintaining a robust maintenance program, you can significantly reduce unscheduled downtime and extend the lifespan of your rolls. Whether it’s addressing surface wear, bearing failures, crowning issues, or preventing corrosion, a systematic approach is always best. Remember, investing in the right maintenance strategies and potentially upgrading components like roll covers or bearings with solutions tailored to your specific needs can pay dividends in the long run. Solving these common problems efficiently keeps your paper machine running smoothly, which, to be honest, is the goal of every mill manager and operator out there.

For more detailed information, please visit our official website: Solving Common Paper Machine Roll Problems: A Quick Guide