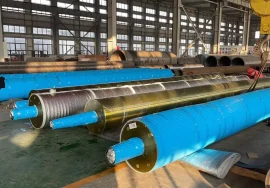

Extend Paper Machine Roller Lifespan: Essential Maintenance Strategies

Paper machines are incredible feats of engineering, transforming raw pulp into finished paper at astonishing speeds. At the heart of this complex machinery are the rollers, cylindrical components that guide, press, dry, and finish the paper web at various stages of production. These rollers operate under immense stress—high pressures, extreme temperatures, corrosive chemicals, and constant abrasion. Given these harsh conditions, it’s no surprise that roller wear and failure are significant concerns for paper manufacturers. A failed roller doesn’t just halt production; it can lead to costly damage, extensive downtime, and significant revenue loss. Therefore, implementing robust and proactive maintenance strategies isn’t just a best practice; it’s absolutely essential for operational efficiency and profitability. The lifespan of these critical components is not solely determined by their initial quality but is heavily influenced by the care and attention they receive throughout their service life. Extending the lifespan of paper machine rollers is a continuous process that requires a deep understanding of their operating environment and the factors that contribute to their degradation.

Understanding the Rigors That Limit Paper Machine Roller Lifespan

To truly appreciate the importance of maintenance strategies in extending paper machine roller lifespan, we must first understand the demanding environment in which they operate. Consider the press section rollers, subjected to enormous nip pressures required to squeeze water from the paper web. This mechanical stress can lead to fatigue, cracking, and cover delamination over time. In the dryer section, rollers face high temperatures, often exceeding 100°C, which can degrade materials and lubricants, accelerate wear, and cause thermal stresses. Furthermore, the paper stock itself can be abrasive, causing gradual surface wear on guiding and forming rollers. Chemical exposure from process additives and recycled fibers introduces corrosive elements that attack roller surfaces and internal components. These combined stresses are relentless and unforgiving. Without effective intervention, they systematically reduce the service life of even the most well-made roller. Recognizing these forces—mechanical load, thermal cycles, abrasion, and chemical attack—is the foundational step in developing maintenance strategies that can counteract their effects and proactively protect the roller’s integrity. Interestingly enough, neglecting any one of these areas can create a domino effect, accelerating wear in other areas and drastically shortening lifespan.

Frankly speaking, the sheer variety of roles and environments within a paper machine means that no two rollers experience the exact same stresses. Forming section rollers deal with water and abrasive fibers at high speeds, while calender rollers face extreme pressure and heat to impart finish. Coating rollers handle viscous, sometimes chemically active, substances. This diversity necessitates tailored maintenance approaches. A one-size-fits-all strategy simply won’t suffice for maximizing lifespan across the entire machine. Understanding the specific operating conditions and typical failure modes for each roller type—whether it’s bearing failure due to lubrication issues in a press roll, cover cracking on a dryer can due to thermal cycling, or excessive wear on a felt roll from abrasive fibers—is paramount. This detailed knowledge allows maintenance teams to prioritize their efforts and apply the most effective strategies where they are needed most, focusing resources on the highest-risk components to achieve the greatest impact on overall paper machine roller lifespan. Have you ever considered the unique challenges faced by each individual roller position in your mill?

The Strategic Imperative of Proactive Inspection for Roller Longevity

One of the most fundamental, yet critically important, essential maintenance strategies for extending paper machine roller lifespan is regular, thorough inspection. Reactive maintenance—waiting for a failure to occur before taking action—is perhaps the most expensive approach possible in the paper industry. Proactive inspection allows potential issues to be identified and addressed *before* they cause catastrophic failure or significant damage. This involves a combination of visual checks, tactile assessments, and increasingly, advanced non-destructive testing (NDT) techniques. Maintenance personnel should be trained to recognize subtle signs of distress, such as slight surface imperfections, discoloration suggesting overheating, unusual noises during rotation, or minor leaks around seals. These seemingly small indicators can be early warnings of major underlying problems. Catching a minor crack in a cover, a bearing showing early signs of wear, or a developing corrosion spot before it propagates extensively can mean the difference between a quick, relatively inexpensive repair and a complete roller replacement, which directly impacts the roller’s overall lifespan.

Beyond visual inspection, implementing more sophisticated diagnostic tools is a powerful strategy. Vibration analysis, for instance, can detect bearing wear or imbalance long before it’s audible or visible, enabling scheduled replacement during planned downtime rather than forcing an emergency stop. Thermal imaging can identify hot spots indicative of friction or electrical issues in motorized rollers or bearings, pointing to lubrication problems or misalignment that could rapidly shorten lifespan. Ultrasonic testing can reveal internal defects in roller shells or bonding layers that are invisible from the surface. These techniques, when used systematically as part of a condition monitoring program, transform maintenance from guesswork into a data-driven science. They provide objective insights into the health of each paper machine roller, allowing for highly targeted maintenance interventions that prevent premature failure and significantly contribute to extending their service life. I’ve found that mills with comprehensive condition monitoring programs consistently achieve longer roller lifespans and experience fewer unexpected breakdowns.

Optimizing Lubrication Protocols: A Core Strategy for Extending Roller Life

Lubrication is undeniably one of the most critical, yet sometimes overlooked, essential maintenance strategies for maximizing paper machine roller lifespan, particularly for bearings and internal mechanisms. Proper lubrication minimizes friction between moving parts, preventing excessive wear and heat generation. In the harsh environment of a paper machine, this is complicated by factors like water ingress, chemical contamination, and extreme temperatures. Using the wrong type of lubricant, applying it incorrectly, or failing to replace degraded lubricant can rapidly accelerate wear and lead to premature bearing failure, a common cause of roller breakdown. A robust lubrication strategy involves selecting lubricants specifically formulated for the operating conditions (temperature range, load, presence of contaminants), determining the correct application method (manual, automated, circulating systems), and establishing appropriate re-lubrication intervals based on usage and environmental factors. It’s worth noting that over-lubrication can be just as detrimental as under-lubrication, leading to seal damage, excessive heat, and potential product contamination. Precision and attention to detail are key.

Implementing a comprehensive lubrication program goes beyond simply adding grease or oil. It includes monitoring lubricant condition through regular analysis. Samples can reveal the presence of contaminants (water, process chemicals, wear particles), changes in viscosity, and the depletion of additives. This analysis provides valuable insights into the effectiveness of the lubrication program and the health of the components being lubricated. For rollers with circulating oil systems, monitoring flow rates, pressure, and temperature is vital. Automated lubrication systems, while requiring initial investment, can significantly improve the consistency and accuracy of lubrication, ensuring that critical points receive the right amount of lubricant at the right time, reducing human error and ensuring continuous protection. Investing in quality lubricants and a well-managed lubrication program is a direct investment in extending the lifespan of your paper machine rollers and avoiding costly, preventable failures. Many experts agree that optimizing lubrication is one of the most impactful steps a mill can take towards improving equipment longevity.

Addressing Wear and Damage Through Timely Repair and Refurbishment Tactics

Even with the best proactive and preventive maintenance, paper machine rollers will eventually experience wear and damage. How these issues are addressed is another essential maintenance strategy that directly impacts the roller’s ultimate lifespan and whether it can be successfully returned to service. Timely and high-quality repair and refurbishment are crucial. Ignoring minor damage allows it to worsen, potentially causing irreversible harm to the roller or damaging other machine components. Common issues requiring attention include surface wear on covers (rubber, polymer, ceramic), corrosion on metal surfaces, damage from foreign objects, and journal or bearing seat wear. Choosing the appropriate repair technique is vital. For rubber covers, this might involve grinding to restore profile or patching minor damage. For metal rolls, it could involve welding, machining, or applying new protective coatings. The goal is not just to fix the immediate problem but to restore the roller’s functionality and integrity to a level that allows it to perform reliably for a significant period, effectively extending its useful life cycle.

The quality of the repair work is paramount. Using inexperienced repair providers or improper techniques can lead to further problems down the line, including premature failure of the repaired area, imbalance issues, or damage to the roller structure. This is where selecting experienced and reputable repair specialists becomes an essential part of your maintenance strategy. They possess the knowledge, equipment, and techniques required for specific roller types and materials. For example, properly applying a thermal spray coating to a metal roll journal requires precision and expertise to ensure adhesion and dimensional accuracy. Regrinding a rubber cover needs to restore the exact crown profile required for proper nip performance. Investing in quality repairs, including potentially upgrading materials or coatings during refurbishment, can not only fix the immediate damage but also enhance the roller’s resistance to future wear, thereby significantly extending its lifespan compared to a quick, low-quality fix or simply running it until it completely fails. Why settle for reactive breakdown maintenance when strategic refurbishment can offer long-term value?

Building a Comprehensive Maintenance Program for Sustainable Roller Lifespan

To truly extend paper machine roller lifespan sustainably, individual maintenance tasks must be integrated into a comprehensive, well-planned program. This moves beyond sporadic inspections or reactive repairs to a structured approach that anticipates needs and optimizes resource allocation. A robust program typically includes scheduled preventive maintenance tasks (like routine lubrication and visual checks), condition-based monitoring (using data from inspection techniques to trigger maintenance), and planned refurbishment cycles based on historical data and expected wear rates. Developing detailed maintenance schedules for each roller based on its position, type, operating conditions, and manufacturer recommendations is a fundamental step. This ensures that critical tasks aren’t missed and that maintenance activities can be coordinated with planned machine shutdowns, minimizing disruptive downtime. Effective planning also involves managing spare parts inventory, including refurbished or spare rollers, to ensure quick changeouts when needed, further reducing downtime associated with roller issues.

Data is the backbone of a truly effective comprehensive maintenance program. Tracking the service history of each roller—when it was installed, its operating hours, any maintenance performed, inspection findings, and failure data—provides invaluable insights. This data allows maintenance managers to identify recurring issues, predict when rollers in similar positions might require attention, and assess the effectiveness of different maintenance strategies or repair techniques. Utilizing CMMS (Computerized Maintenance Management Systems) or EAM (Enterprise Asset Management) software can significantly streamline data collection, analysis, scheduling, and work order management. These systems help organize the complex logistics of maintaining hundreds of rollers on a paper machine, ensuring that maintenance is performed systematically and efficiently. Implementing a data-driven, comprehensive maintenance program transforms roller care from a series of tasks into a strategic asset management function focused on maximizing operational availability and extending paper machine roller lifespan through proactive, informed decisions. In my experience, mills that effectively leverage data in their maintenance planning see dramatic improvements in asset reliability.

The Impact of Materials Science and Coatings on Roller Durability

While ongoing maintenance is crucial, the initial material selection and any subsequent coatings applied to paper machine rollers play a foundational role in their potential lifespan. This isn’t strictly maintenance in the traditional sense, but it’s an ‘essential strategy’ for ensuring longevity from the outset and is often integrated into refurbishment processes. The core material of the roller shell (steel, cast iron, composite) provides structural integrity, but the surface material or cover is what directly interacts with the paper web, felts, and process environment. Different applications require vastly different cover properties. For example, rubber covers offer elasticity and grip, while ceramic coatings provide extreme hardness and wear resistance. Selecting a cover material with appropriate resistance to abrasion, chemicals, heat, and mechanical fatigue for its specific position in the machine is a critical decision that impacts how long the roller can perform effectively before requiring maintenance or replacement. An inappropriate cover material will wear out prematurely, regardless of lubrication or inspection efforts, drastically shortening the roller’s lifespan.

Advances in materials science have led to the development of highly specialized coatings and cover compounds designed to withstand the unique stresses of paper machine environments. These include advanced polymers, composites, metallic coatings, and ceramics. Applying a specialized coating or cover during manufacturing or refurbishment can significantly enhance a roller’s durability and resistance to specific types of wear or corrosion. For instance, hard chrome plating or thermal spray coatings can protect metal journals and surfaces from corrosion and wear. Ceramic coatings offer exceptional hardness for abrasive applications. Choosing the right material solution is a strategic decision that forms a crucial part of extending paper machine roller lifespan. It’s an investment that pays off by reducing the frequency of required maintenance and replacement over the roller’s service life. Our company specializes in providing material solutions and coatings that are engineered to meet the demanding conditions faced by paper machine rollers, directly supporting efforts to maximize their longevity.

Leveraging Technology and Expertise in Roller Maintenance Strategies

Successfully implementing essential maintenance strategies to extend paper machine roller lifespan relies heavily on both technological tools and human expertise. Modern maintenance technology offers capabilities far beyond traditional methods. We’ve touched upon condition monitoring tools like vibration analysis and thermal imaging, but this also extends to advanced diagnostic software, laser alignment tools for ensuring proper roller geometry and parallelism, and even remote monitoring systems that allow experts to assess roller health from a distance. Leveraging these technologies provides more accurate, objective data, enables predictive capabilities, and improves the efficiency of maintenance tasks. However, technology is only as effective as the people using it. Properly training maintenance personnel on how to use these tools, interpret the data they provide, and execute maintenance tasks correctly is paramount. A well-trained technician can spot a subtle issue during an inspection that a less experienced eye might miss, or correctly diagnose a problem based on vibration data.

Furthermore, collaborating with external experts, such as roller manufacturers or specialized maintenance service providers, can significantly enhance a mill’s ability to extend roller lifespan. These partners often possess deep knowledge about specific roller designs, failure modes, and advanced repair or coating techniques that may not be available in-house. They can provide expert assessments, perform complex repairs, offer training, and advise on the best materials and maintenance practices for particular applications. Developing strong relationships with such partners becomes an essential strategy in itself, providing access to specialized expertise and resources that complement the mill’s internal capabilities. This combination of cutting-edge technology, skilled internal teams, and strategic external partnerships creates a powerful framework for implementing effective maintenance strategies that genuinely extend the service life of paper machine rollers, ensuring reliable and efficient paper production.

Extending paper machine roller lifespan through essential maintenance strategies is a multifaceted undertaking that requires a holistic approach. It begins with understanding the unique stresses each roller faces and then implementing proactive measures across inspection, lubrication, timely repair, and strategic planning. Selecting the right materials and coatings provides a durable foundation, while leveraging technology and developing expertise ensures that maintenance efforts are effective and efficient. By focusing on these core strategies—from the initial design and material selection to daily operational care and planned refurbishment—paper mills can significantly reduce costly downtime, improve operational efficiency, and maximize their investment in these critical components. It’s a continuous cycle of monitoring, analysis, and action that pays dividends in reliability and profitability, ensuring paper machines can run smoothly and productively for years to come.

For more detailed information, please visit our official website: Extend Paper Machine Roller Lifespan: Essential Maintenance Strategies