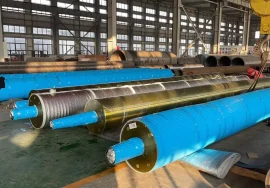

Highly Efficient Combination Roll for Toilet Paper Machines

The production of toilet paper is a fascinatingly intricate process, demanding precision, speed, and reliability at every stage. At the heart of this process, particularly in the critical dewatering and pressing sections, lies the vital role of specialized rolls. Among these, the concept of a “combination roll” stands out, especially when engineered for achieving high efficiency. Frankly speaking, optimizing the performance of these rolls is not just about making paper; it’s about maximizing output, conserving energy, and ensuring consistent product quality. A highly efficient combination roll is far more than just a cylinder; it represents a sophisticated piece of engineering designed to manage immense pressures and rapidly remove water from the delicate paper web as it travels towards the dryer. This combination of functions within a single roll is what gives it its name and its inherent potential for streamlining the process. Understanding its design, function, and impact is crucial for anyone involved in operating or improving modern toilet paper production lines. It’s the kind of component that can significantly differentiate a high-performing machine from a standard one, directly influencing profitability and sustainability goals. The focus on “highly efficient” isn’t mere marketing jargon; it speaks to tangible improvements in dewatering rates, reduced energy consumption by downstream drying equipment, and ultimately, faster machine speeds without compromising the paper’s structural integrity or softness. Have you ever considered just how much engineering goes into removing water from a flimsy paper web at hundreds, sometimes over a thousand, meters per minute?

Understanding the Combination Roll Concept for Highly Efficient Toilet Paper Production

To truly appreciate the “highly efficient combination roll” in the context of toilet paper machines, we first need to dissect what a combination roll entails. In traditional press sections of paper machines, different rolls performed distinct functions – maybe a blind-drilled press roll, a grooved roll, or a suction roll, often interacting with felts to extract water. The “combination” aspect signifies a design where multiple functions are integrated into a single roll body. This typically involves features like internal suction capabilities combined with a specialized outer surface (e.g., grooves, blind holes, or specific cover materials) to achieve more effective dewatering within a single nip. For toilet paper, which is inherently low basis weight and designed for absorbency (meaning it holds water tenaciously initially), efficient dewatering early in the process is absolutely critical. Every percentage point of water removed mechanically in the press section saves significant energy compared to removing it thermally in the Yankee dryer. Therefore, a combination roll designed specifically for this challenging application aims to maximize water removal in a single pass or within a simplified press configuration. This integration inherently reduces the complexity of the press section, potentially allowing for a more compact machine design and fewer felt runs, which also contributes to stability and ease of operation. The synergy created by combining suction and pressing/surface features in one roll is key to unlocking higher levels of efficiency compared to using discrete rolls for each function. It’s a clever engineering solution to a fundamental challenge in papermaking: getting water out quickly and cleanly without damaging the delicate web.

The Role of Integrated Suction in Combination Rolls

A primary feature contributing to the “highly efficient” aspect of many combination rolls for toilet paper machines is the integration of suction. Unlike conventional press rolls that rely solely on mechanical pressure and the capillary action of felts to draw water away, a combination roll with suction actively pulls water through the paper web and into internal channels or chambers within the roll itself. This is particularly effective for light basis weight sheets like toilet paper, which can collapse under excessive pressure if water doesn’t have a rapid escape route. The suction creates a pressure differential that helps overcome the hydraulic pressure built up in the nip, drawing water out of the sheet and into the felt, and then into the roll’s vacuum system. The design of the suction box inside the roll – its width, vacuum level, and positioning relative to the nip – is critical. Modern designs optimize these factors to provide targeted, powerful dewatering precisely when and where it’s needed. This active water removal mechanism is a step change from relying solely on pressing, allowing for faster dewatering rates and drier sheets exiting the press section. Interestingly enough, the efficiency of this suction is also dependent on the permeability of the felt running with the roll, creating a dynamic interaction that needs careful management. Optimizing both the roll’s suction capabilities and the felt design is paramount for maximizing the “highly efficient” performance sought after in high-speed toilet paper production.

Achieving “Highly Efficient” Performance: Technical Aspects of Combination Rolls

The term “highly efficient” isn’t just about speed; it’s about how effectively the combination roll performs its function – primarily dewatering and consolidating the paper web – using minimal energy and without detrimental effects on the product or machine. Several technical aspects contribute to this high efficiency. The roll’s surface is paramount. Whether it features blind holes, grooves, or a specific type of cover material, the surface must facilitate rapid water transfer away from the sheet while providing the necessary pressure for consolidation. The pattern and depth of holes or grooves are meticulously designed to manage hydraulic pressure within the nip and provide pathways for water removal. Furthermore, the material and design of the roll shell itself are crucial forwithstanding the significant pressures involved and ensuring dimensional stability at high speeds. Internal design, particularly concerning suction rolls, involves precisely machined suction boxes and internal piping to maintain consistent vacuum levels across the roll face and efficiently remove aspirated water and air. The dynamic behavior of the roll at operating speed, including crown profile and vibration characteristics, also plays a significant role in achieving uniform dewatering and preventing sheet breaks, both of which are indicators of efficient operation. Frankly speaking, the engineering tolerances involved in manufacturing these rolls are incredibly tight, as even minor imperfections can lead to uneven pressure profiles or inefficient suction, directly impacting dewatering performance and sheet quality. It’s a complex interplay of mechanics, fluid dynamics, and material science.

Surface Design and Materials for Optimal Water Removal

Delving deeper into the technicalities, the surface of a highly efficient combination roll is where the action truly happens regarding dewatering. For rolls incorporating suction, the outer shell is typically drilled with thousands upon thousands of precisely sized and angled holes. These holes connect to the internal suction box, allowing vacuum to pull water through the felt and paper web. The pattern, diameter, and depth of these blind-drilled holes, or the configuration of grooves, are not arbitrary. They are optimized based on the paper grade, machine speed, and desired dryness target. The goal is to maximize open area for water removal while maintaining sufficient land area to support the pressure load without damaging the paper or felt. The cover material applied to the roll surface is equally important. Modern combination rolls often feature specialized polymer or rubber covers engineered for specific properties like abrasion resistance, chemical resistance, thermal stability, and elasticity. These covers can be softer or harder depending on the desired nip characteristics and paper properties. A properly selected and maintained cover ensures uniform pressure application, prevents sticking, and contributes significantly to dewatering efficiency and roll longevity. The synergy between the internal suction mechanism, the surface pattern, and the cover material is what elevates a standard roll to a “highly efficient combination roll,” enabling the machine to run faster and drier.

Practical Benefits of Implementing Highly Efficient Combination Rolls in Toilet Paper Machines

Implementing highly efficient combination rolls in a toilet paper machine translates directly into tangible benefits that impact the bottom line. Perhaps the most significant advantage is improved dewatering in the press section. By removing more water mechanically before the sheet reaches the energy-intensive Yankee dryer, the machine consumes less thermal energy, leading to substantial cost savings on steam and fuel. This drier sheet entering the dryer section also allows for potentially higher machine speeds, boosting overall production capacity. Increased speed and reduced energy consumption are key indicators of “highly efficient” operation. Furthermore, effective and uniform dewatering helps improve sheet quality and strength properties. By removing water consistently across the web width, the risk of uneven moisture profiles (which can lead to cockling or tearing) is reduced. The combined pressing and suction action also aids in consolidating the sheet structure uniformly. In my experience, well-designed combination rolls contribute to fewer sheet breaks in the press and dryer sections, leading to higher runnability and less downtime. This enhanced reliability is invaluable in a high-speed production environment. Reduced complexity in the press section, thanks to combining multiple functions into one roll, can also simplify maintenance procedures and lower spare parts inventory. It’s worth noting that the impact of such a component ripples through the entire production line, affecting everything from energy bills to finished product quality.

Impact on Energy Consumption and Production Speed

Focusing on the “highly efficient” aspect, the impact on energy consumption and production speed is particularly noteworthy for combination rolls. Toilet paper production is inherently energy-intensive, with drying consuming a significant portion of the total energy used. Any improvement in mechanical dewatering, however slight, yields disproportionate energy savings downstream. A highly efficient combination roll, by maximizing water removal in the press nip, reduces the moisture load on the Yankee dryer. This means less steam is required to evaporate the remaining water, directly cutting energy costs and lowering the machine’s carbon footprint. Simultaneously, removing more water earlier allows the sheet to withstand higher stresses and speeds in the dryer section and beyond. A drier sheet is stronger and less prone to breaks at high velocity. Thus, a combination roll engineered for high efficiency acts as a bottleneck opener, enabling faster machine speeds without sacrificing quality or increasing breaks. Many experts agree that optimizing the press section, specifically through advanced roll technology like highly efficient combination rolls, is one of the most effective ways to boost capacity and reduce operating costs in existing toilet paper machines. It’s a clear example of how focused engineering on a critical component can unlock system-wide performance improvements. Have you ever calculated the potential energy savings from reducing sheet moisture by just one or two percentage points?

Ensuring Longevity and Maintaining Efficiency of Combination Rolls

The upfront investment in a highly efficient combination roll is justified by its potential for long-term performance and savings. However, maintaining that “highly efficient” status over the roll’s lifespan requires diligent care and attention. Regular inspection is paramount, checking for wear on the cover, damage to holes or grooves, and the integrity of internal components, particularly the suction box seals and bearings. Proper roll grinding and covering schedules, based on wear patterns and material properties, are essential to maintain the correct crown profile and surface characteristics necessary for uniform dewatering and pressure application. Maintenance of the vacuum system associated with the combination roll is also critical. Ensuring consistent and optimal vacuum levels is key to the suction mechanism’s effectiveness. Leaks or pump issues will directly reduce dewatering efficiency. Furthermore, proper storage and handling when the roll is out of the machine are vital to prevent damage to the precision-engineered surface and internal components. The operating environment, including furnish quality and chemical usage, can also impact roll life and performance, necessitating appropriate cleaning procedures to prevent clogging of holes or deterioration of the cover material. Frankly speaking, neglecting maintenance on a highly efficient combination roll is akin to detuning a high-performance engine; you simply won’t get the intended efficiency or lifespan.

Maintenance Practices for Peak Combination Roll Performance

Maintaining the peak performance of a highly efficient combination roll in a toilet paper machine is an ongoing process that involves several key practices. Regular cleaning is crucial to prevent the accumulation of fibers, fillers, and chemicals in the surface holes or grooves, which can significantly impede dewatering efficiency. High-pressure showering systems or chemical cleaning solutions, carefully selected to be compatible with the roll cover material, are often employed. Monitoring roll vibrations and bearing temperatures can provide early warning signs of mechanical issues before they lead to costly downtime or damage. Consistent monitoring of key performance indicators, such as sheet dryness after the press and energy consumption in the dryer, allows operators to track the roll’s efficiency over time and schedule maintenance proactively rather than reactively. When regrinding or recovering is required, using qualified service providers with expertise in precision roll maintenance is essential to ensure the roll is returned to specification. The choice of cover material during recovering should always align with the specific operating conditions and desired performance characteristics of the toilet paper machine. Our company understands the importance of maximizing the return on investment in such critical components. We offer services and products designed to help maintain the efficiency and extend the life of highly efficient combination rolls, ensuring they continue to contribute optimally to your production goals.

Selecting the Right Highly Efficient Combination Roll for Your Toilet Paper Machine

Choosing the appropriate highly efficient combination roll is not a one-size-fits-all decision. It requires careful consideration of several factors specific to your toilet paper machine and production goals. Key parameters include the machine’s design speed, the types of fiber furnish used, the desired paper quality (e.g., softness, strength, absorbency), and the existing press section configuration. The target sheet dryness after the press is a critical specification that the roll must be designed to help achieve. Roll diameter, face length, cover type and hardness, and the specific design of the internal suction system must all be matched to the machine’s requirements. The operating pressure and temperature ranges are also important considerations for material selection and roll construction. Furthermore, thinking about ease of maintenance and longevity is part of selecting a truly “highly efficient” roll over its operational life. A roll that performs well initially but requires constant attention or fails prematurely isn’t truly efficient in the long run. Partnering with a supplier who possesses deep expertise in roll technology for tissue and toilet paper applications is invaluable during the selection process. They can help analyze your specific needs and recommend a combination roll design optimized for your machine’s unique characteristics, ensuring you invest in a component that delivers maximum efficiency and return. Why settle for standard performance when highly efficient solutions are available?

The Future of Highly Efficient Combination Rolls in Toilet Paper Production

Looking ahead, the drive for even higher efficiency in toilet paper production will continue to push the boundaries of combination roll technology. We can anticipate further advancements in roll cover materials, potentially offering enhanced dewatering properties, increased durability, and improved resistance to challenging operating conditions. The design of internal suction systems may become even more sophisticated, perhaps incorporating variable vacuum control across the roll width or more energy-efficient vacuum generation methods. Sensor technology integrated into the rolls could become more common, providing real-time data on pressure distribution, temperature, and vibration, enabling predictive maintenance and even dynamic adjustment of operating parameters for optimal efficiency. As machine speeds increase, the mechanical demands on combination rolls will become even greater, requiring innovations in roll shell materials and construction techniques to ensure stability and safety. The focus will remain on maximizing water removal with minimal energy input while simultaneously contributing to improved paper quality and machine runnability. It’s fascinating to think about how these critical components, seemingly simple cylinders, will continue to evolve through advanced engineering and material science to meet the ever-growing global demand for sustainable and efficient toilet paper production. The highly efficient combination roll is not a static technology; it’s a continuously developing solution at the forefront of press section innovation.

In conclusion, the highly efficient combination roll is a cornerstone technology in modern toilet paper machines, embodying sophisticated engineering aimed at optimizing the critical dewatering process. By integrating functions like suction and pressing with advanced surface designs and materials, these rolls significantly improve energy efficiency, increase production speed, enhance paper quality, and boost machine reliability. Achieving and maintaining this high level of efficiency requires careful selection, proper operation, and diligent maintenance. As the industry strives for greater sustainability and higher output, the role of these specialized rolls will only become more pronounced, driving continuous innovation in their design and application. Our company is committed to developing and providing components and services that support the high efficiency demands of contemporary toilet paper production lines. We understand the challenges producers face and offer solutions designed to optimize the performance and longevity of critical press section components.

For more detailed information, please visit our official website: Highly Efficient Combination Roll for Toilet Paper Machines