Boost Production with Highly Efficient Combination Rolls

In the world of paper manufacturing, particularly when it comes to producing something as ubiquitous and essential as toilet paper, efficiency isn’t just a buzzword; it’s the lifeblood of a successful operation. The machinery involved is complex, and every component plays a critical role in ensuring smooth, high-speed production. Among these vital parts, the rolls within the paper machine stand out. They are subjected to immense pressures, varying temperatures, and constant abrasion, all while handling delicate paper webs at incredible speeds. Achieving optimal performance under these conditions requires not just any roll, but components specifically designed for maximum efficiency and durability. This is where the concept of a highly efficient combination roll for toilet paper machines becomes paramount – a specialized component engineered to deliver superior results in a demanding environment, directly impacting output, quality, and overall mill profitability.

Understanding the Combination Roll’s Role in Tissue Production

To truly appreciate the value of a highly efficient combination roll in the context of toilet paper manufacturing, we first need to understand its specific function. In a paper machine, a combination roll typically refers to a roll that performs multiple tasks, often related to dewatering and pressing the paper web. Think about the journey of the paper web from the forming section, where it’s mostly water, through the press section, where water is mechanically squeezed out. A combination roll might function as a press roll working in conjunction with another roll, or it might incorporate vacuum technology to assist in dewatering simultaneously. The goal is always the same: to remove as much water as possible before the expensive drying phase, while also compacting the web to give it strength and structure, all without damaging the delicate tissue sheet. The pressures are high, the surface interactions are critical, and the speed is relentless. A roll that falters here means lower dry content, higher energy costs in drying, reduced machine speed, and potential quality issues. Frankly speaking, it’s a high-stakes part of the process.

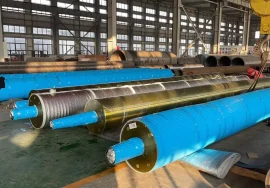

Components and Basic Operation Within the Press Section

Let’s delve a bit deeper into what makes up a combination roll designed for this intense environment. While configurations vary, a common combination roll might feature a robust core structure, often steel, covered with a specialized surface material. This surface is absolutely crucial – it needs to withstand significant nip pressures (the force exerted where two rolls meet), resist wear from the paper web and any potential contaminants, and maintain specific surface properties (like hardness, porosity, or even vacuum capability). Some combination rolls incorporate internal vacuum zones, requiring complex internal drilling patterns and sealing mechanisms to pull water out of the web as it passes through the nip. Others might focus purely on mechanical pressing, utilizing advanced cover materials that optimize dewatering and minimize rewetting. The operational principle is simple: apply controlled pressure and/or vacuum to squeeze water from the paper web, preparing it for subsequent drying. However, achieving this simply is challenging; achieving it *highly efficiently* requires advanced engineering and material science.

Why Efficiency is Paramount for Toilet Paper Manufacturing

In the competitive world of toilet paper production, margins can be tight, and operational efficiency is key to staying profitable. A paper machine’s throughput is largely dictated by its speed, and the press section is often a bottleneck if dewatering isn’t optimized. The better the rolls perform in removing water mechanically, the less work the energy-hungry dryers have to do. This directly translates into lower energy consumption (a significant cost in paper making), higher potential machine speeds, and ultimately, more finished product per hour. Moreover, efficient pressing impacts paper quality – consistent dewatering leads to more uniform sheet properties, reducing breaks and improving the final product’s characteristics like bulk and softness. Downtime is incredibly costly; a roll failure or even suboptimal performance requiring frequent maintenance directly eats into production time. This is why investing in a highly efficient combination roll is not just an upgrade; it’s a strategic decision aimed at maximizing output and minimizing operational expenses in the long run. It’s worth noting just how much a seemingly small improvement in dewatering can cascade into massive savings and production gains.

Engineering the Highly Efficient Combination Roll: Key Innovations

So, what sets a highly efficient combination roll for toilet paper machines apart from a standard roll? It comes down to innovation in design, materials, and manufacturing precision. Modern high-efficiency rolls utilize advanced composite covers or specialized rubber formulations that offer superior resistance to heat, chemicals, and abrasion compared to older materials. These covers are engineered with specific hardness profiles and surface textures (like intricate groove patterns or blind drilling) designed to optimize water removal in the nip. The internal structure, especially for vacuum rolls, involves sophisticated drilling patterns and vacuum box designs that maximize water extraction while minimizing air leakage. Bearing and sealing technologies are also critical, designed for high speeds and pressures to ensure smooth operation and prevent lubricant contamination. Interestingly enough, the precision engineering extends to balancing the roll, which is essential for high-speed operation to prevent vibrations that could compromise paper quality or machine health. It’s a blend of mechanical engineering, material science, and fluid dynamics all working in concert to achieve peak performance.

Materials and Surface Technologies for Enhanced Performance

The surface of the combination roll is arguably where much of its efficiency gain originates. Traditional rubber covers have limitations in terms of durability and specific dewatering characteristics. Highly efficient rolls often feature advanced synthetic covers, including polyurethanes or specialized composites, sometimes incorporating ceramic particles or other fillers to enhance wear resistance and grip. Surface patterns are meticulously designed – blind drilled patterns create voids for water to escape into under pressure, while sophisticated grooving patterns can help manage water flow laterally. For vacuum rolls, the cover material needs to be precisely drilled with thousands of holes, and the internal sealing strips must maintain tight contact against the cover’s inner surface under high pressure to ensure efficient vacuum suction. The interface between the paper web and the roll surface is critical; the right material and texture can reduce sticking, minimize lint buildup, and promote consistent dewatering across the width of the roll. This focus on the contact surface is a major factor in optimizing toilet paper machine roll performance.

Tangible Benefits of Upgrading to Highly Efficient Combination Rolls

Upgrading to a highly efficient combination roll for your toilet paper machine brings a cascade of benefits that directly impact your bottom line. Firstly, improved dewatering in the press section means the paper web enters the dryers with a lower moisture content. This leads to significant savings in energy consumption, as less water needs to be evaporated. Secondly, with better dewatering and reduced sheet breaks (due to more uniform pressing and less sticking), the machine can often run at higher speeds, dramatically increasing production throughput. Think about the impact of even a 5% increase in speed over a year – it’s substantial. Thirdly, consistent and effective pressing improves the quality of the finished paper, leading to fewer rejects and higher customer satisfaction. Furthermore, advanced materials and robust construction mean these highly efficient rolls typically have longer service lives and require less frequent maintenance or regrinding, reducing downtime and maintenance costs. Have you ever calculated the cost of unexpected downtime? It’s enormous, and reliable rolls are a key defense against it.

Selecting the Right Combination Roll for Your Machine

Choosing the correct highly efficient combination roll isn’t a one-size-fits-all decision. It requires careful consideration of several factors specific to your operation. The type of toilet paper machine you have (e.g., crescent former, conventional fourdrinier), the grades of tissue paper you produce (basis weight, furnish), the desired machine speed, and the operating pressures in your press section all play a crucial role. You need to consider the existing machine setup, including the mating roll it will work against. Material compatibility, nip width requirements, and the specific dewatering challenges you face should guide your selection. Frankly speaking, this often requires collaboration with a knowledgeable supplier who can analyze your specific needs and recommend a roll designed to optimize performance within your unique setup. It’s not just about buying a part; it’s about investing in a solution that integrates seamlessly and delivers measurable improvements. Optimizing toilet paper machine performance starts with understanding the nuances of your current system.

Ensuring Longevity Through Proper Roll Care

Even the most technologically advanced, highly efficient combination roll requires proper care and maintenance to deliver its peak performance over its lifespan. Regular inspections are essential to check for wear, damage, or cover degradation. Monitoring operating parameters like temperature, pressure, and vibration can provide early warnings of potential issues. Proper cleaning procedures are vital to prevent buildup that could affect dewatering efficiency or damage the roll surface. Routine grinding or recovering may be necessary over time, and this work should be performed by experienced professionals using the correct techniques and equipment. Storing spare rolls correctly, protecting their surfaces from damage and environmental factors, is also a simple but crucial step. Investing in a high-efficiency roll is important, but protecting that investment through diligent maintenance practices is what ensures you reap the benefits for years to come. Combination press roll maintenance for paper mills is a specialized skill set that pays significant dividends.

Addressing Your Production Challenges with Advanced Rolls

Many paper manufacturers face common challenges: the need to increase production speed, reduce energy costs, improve paper quality consistency, and minimize costly downtime. Traditional roll technologies can sometimes become a limitation to achieving these goals. This is precisely where advanced, highly efficient combination rolls for toilet paper machines offer a compelling solution. By incorporating cutting-edge materials, precision engineering, and designs optimized for maximum dewatering and durability, these rolls can help break through existing bottlenecks. They are engineered to withstand the rigors of high-speed tissue production, providing consistent, reliable performance day in and day out. If you’re looking to push the limits of your tissue machine’s capabilities and achieve new levels of operational excellence, upgrading your rolls is a step that can deliver significant, measurable results. Advanced roll technology for tissue production is continuously evolving, offering new opportunities for improvement.

In conclusion, the highly efficient combination roll for toilet paper machines is far more than just a cylindrical component; it’s a key technology enabler for modern, high-speed tissue production. Its ability to dramatically improve dewatering efficiency translates directly into energy savings, increased machine speed, enhanced paper quality, and reduced downtime. Investing in these advanced rolls is a strategic move for any paper manufacturer aiming to optimize their operations and maintain a competitive edge in the market. Understanding their function, the innovations behind their efficiency, and the importance of proper selection and care is crucial for maximizing their benefits. If you’re experiencing limitations with your current rolls or simply looking for ways to boost your tissue machine’s performance, exploring the options in highly efficient combination rolls is a logical next step.

For more detailed information, please visit our official website: Highly Efficient Combination Roll for Toilet Paper Machines