In the intricate world of paper manufacturing, particularly when it comes to producing something as ubiquitous and essential as toilet paper, every component of the machinery plays a critical role. Among these myriad parts, rollers stand out as fundamental workhorses, guiding, pressing, and forming the pulp into the final product. While modern technology has introduced a range of materials and designs, the traditional or specialized stone roller holds a unique place in the history and ongoing operation of paper mill machinery, especially in specific applications or older machines. Understanding the specific function and characteristics of a stone roller within the complex system of paper production equipment, tailored for the delicate requirements of toilet paper, is key to appreciating the nuances of this industry. Frankly speaking, achieving the desired quality, consistency, and absorbency in toilet paper isn’t merely about the pulp composition; it’s profoundly influenced by the mechanical processes, and that’s where the right roller, potentially a stone one, becomes indispensable. It’s worth noting that the term “stone roller” can encompass various materials and designs used over time, each bringing distinct properties to the process.

The Essential Role of Rollers in Paper Mill Machinery

Paper mill machinery is a marvel of engineering, a long and often massive system designed to transform a slurry of fibers into a continuous sheet of paper. Within this system, rollers perform a multitude of vital functions. They transport the wet web of fibers through different sections of the machine, from the forming section where water is initially drained, through the press section where more water is squeezed out mechanically, and into the dryer section. Rollers also play a crucial role in calendering, which is about smoothing the paper surface, and winding the final product. Different rollers are designed for specific tasks and locations; couch rolls remove water after forming, press rolls dewater the sheet, guide rolls ensure the web travels correctly, and calender rolls affect surface finish. The material, surface finish, diameter, and even internal structure of a roller are all carefully chosen based on its specific job and the type of paper being produced. For operations involving tissue or toilet paper, these choices are particularly sensitive due to the need for softness and bulk, achieved through careful control of moisture removal and web handling. This is where the traditional properties offered by certain materials, including stone, historically came into prominence, and continue to be relevant in certain contexts or for understanding the evolution of the machinery.

Functions of Different Roller Types in Paper Production

Digging a little deeper into the functions, consider the press section. Here, the goal is to remove as much water as possible from the paper web using mechanical pressure. This is far more energy-efficient than removing water through drying with heat. Press rolls, operating in nips (the point where two rolls come together), apply immense pressure. The material and surface pattern (or lack thereof) of these rolls directly impact dewatering efficiency and the bulk and strength characteristics of the final paper. In other sections, like the dryer section, guide rollers made of various materials must withstand high temperatures and maintain precise alignment to prevent web breaks. Forming rolls and couch rolls handle the very wet, fragile web at the beginning of the process, requiring materials that facilitate water removal without damaging the nascent sheet. Each roller is a specialized component, engineered for performance and durability under demanding conditions of moisture, heat, pressure, and continuous operation. The choice of material, whether it’s granite, steel, synthetic polymers, or potentially even a composite designed to mimic desirable stone properties, directly impacts the operational efficiency, the lifespan of the roller itself, and ultimately, the quality of the paper produced. This highlights why the specific material, like stone in certain applications, warrants focused attention.

Why Stone Rollers for Toilet Paper Production? Analyzing the Suitability

Historically, stone rollers, particularly those made of materials like granite, were widely used in paper machines. Granite, for instance, possesses properties that were highly valued. Its hardness offered durability, while its natural porosity could aid in water removal in certain applications, acting almost like a natural felt. Furthermore, a finely ground and polished granite surface provided a stable and consistent nip in press sections, contributing to even dewatering and a uniform paper web. For toilet paper production, which emphasizes softness and absorbency, the specific interaction between the roller surface and the delicate paper web is crucial. Excessive pressure applied too quickly or with a harsh surface could compact the fibers too much, reducing bulk and softness. A stone roller’s traditional characteristics, such as its thermal stability and specific surface energy, could influence how the wet web behaves under pressure and during initial drying stages. Interestingly enough, while many modern machines utilize synthetic covers on metal cores to replicate or improve upon desired surface properties, the legacy of stone rollers provides insight into the fundamental requirements of roller surfaces in paper manufacturing. Have you ever considered how the surface texture of a roll could impact something as simple as how soft your toilet paper feels? It’s these seemingly minor details that are engineered into the machinery.

Specific Characteristics of Stone Materials Relevant to Paper Mills

Let’s delve a bit deeper into the characteristics of stone materials that made them relevant for paper mill machinery, especially pertinent to products like toilet paper. Materials like granite, often used for rolls, possess excellent compressive strength, allowing them to withstand the high pressures in a press nip without deformation. Their natural hardness contributes to wear resistance, crucial for components in constant contact with abrasive paper fibers and chemicals. Furthermore, some stones have a natural porosity, albeit very fine, which could potentially assist in managing the flow of water out of the paper web in pressing applications, reducing the risk of crushing or “sheet marking.” While modern materials can be engineered with precise porosity and surface energy, the inherent properties of stone provided a functional solution for many years. Maintaining these stone surfaces involved specialized grinding and polishing techniques to ensure the required precision and smoothness, or controlled roughness, depending on the roller’s function. The thermal properties of stone, its ability to maintain temperature, could also be a factor in consistency during continuous operation, particularly in sections where temperature control is important for drying or conditioning. Understanding these material properties helps illuminate why stone was a go-to choice for critical rollers for so long.

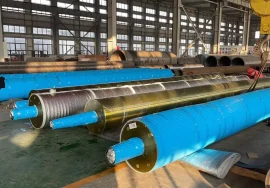

Integration of Stone Rollers within the Toilet Paper Machinery Line

Within the complex architecture of a paper machine configured for producing toilet paper, stone rollers, where still utilized or in historical context, would typically be found in sections where their unique properties offered an advantage. For example, in the press section, a granite roll might be used in conjunction with a softer, felt-covered roll to form a nip that dewaters the sheet while aiming to preserve bulk. In older machines, granite couch rolls were also common, positioned after the forming section to support the newly formed web and assist in initial water removal through vacuum. Guide rolls, responsible for maintaining web tension and path, could also be made of stone, valued for their stability and resistance to deflection under tension. The integration wasn’t just about placing a roller; it involved careful alignment, balancing, and bearing design to ensure smooth, vibration-free operation at speed. The sheer weight of large stone rollers also required robust machine frames and foundations. The specific placement and function within the machine line for toilet paper production underscore the fact that the choice of roller material and design is highly application-specific, aimed at optimizing the process for the desired end-product characteristics. It’s a testament to the ingenuity of early paper engineers who leveraged natural materials effectively.

Specific Applications in Toilet Paper Production Steps

Let’s consider the journey of the paper web specific to toilet paper production and where stone rollers might have played a part. After the pulp is formed into a wet sheet on the wire, the sheet moves to the press section. Here, press rolls reduce the water content significantly. A stone press roll, perhaps in combination with other roll types, would apply pressure to squeeze out water. The surface of this roll, whether smooth or slightly textured, would influence the dewatering efficiency and how the fibers are consolidated, which directly impacts the final softness and bulk of the tissue. Further down the line, guide rolls, potentially stone, would ensure the delicate web travels smoothly towards the dryer section, preventing wrinkles or tears. While many modern high-speed machines rely heavily on advanced materials and technologies, the principles established with traditional rollers, including stone, remain foundational. The precision required in setting the nip pressure, maintaining roll surface integrity, and ensuring perfect alignment is paramount, regardless of the roller material. Any imperfection in a roller, especially a critical one like a press roll, can lead to inconsistencies in paper caliper, moisture content, and even web breaks, all of which are particularly undesirable when producing a thin, delicate product like toilet paper.

Maintaining and Managing Stone Rollers in Paper Mill Machinery

Like all components in demanding industrial machinery, stone rollers require regular maintenance to ensure optimal performance and longevity. The hard surface of granite rollers is resistant to wear, but over time, they can develop uneven wear patterns, grooves, or surface imperfections due to constant contact with the paper web, felts, and potential contaminants. To counteract this, periodic grinding is essential. This process involves precision machining the roller surface to restore its cylindrical profile and desired surface finish. This isn’t a simple task; it requires specialized grinding equipment and skilled technicians to remove minimal material while achieving very tight tolerances for diameter, straightness, and surface roughness. Furthermore, cleaning is crucial to prevent the buildup of fibers, fillers, and chemicals on the roller surface, which could affect paper quality and dewatering efficiency. Damage from foreign objects entering the nip is also a risk, potentially causing chips or cracks that necessitate repair or replacement. Frankly speaking, maintaining large, heavy stone rollers is a significant undertaking requiring specialized knowledge and equipment, highlighting the commitment needed to keep paper mill machinery running smoothly. This maintenance aspect is a key operational consideration for mills utilizing or maintaining machines with stone rollers.

Challenges and Considerations for Stone Rollers

Working with and maintaining stone rollers in the context of active paper mill machinery, especially those geared towards products like toilet paper, presents specific challenges. Their sheer weight and size make handling and installation complex and potentially hazardous. Precision grinding requires the roller to be removed from the machine and transported to a specialized facility or necessitate bringing portable grinding equipment to the site. This downtime must be carefully scheduled to minimize impact on production. While hard, stone can be brittle compared to metals, making them susceptible to chipping or cracking from impact. Detecting internal flaws is also more challenging than with metallic rolls, though modern non-destructive testing methods can help. Furthermore, achieving and maintaining the exact desired surface properties – the specific level of smoothness or controlled roughness – on a stone surface consistently over the roller’s lifespan is a skilled process. The thermal expansion properties of stone are also different from metals, which needs to be accounted for in bearing design and machine operation, particularly in sections involving significant temperature fluctuations, such as near dryers. These factors explain why, in many modern, high-speed applications, alternative materials like metal cores with specialized composite or polymer covers are often chosen, as they can offer engineered properties, lighter weight, and potentially easier maintenance. However, the principles learned from stone rollers continue to influence modern designs.

Modern Alternatives and the Enduring Relevance of Stone Rollers

Today’s paper mill machinery, including that used for the high-speed production of toilet paper, predominantly features rollers made from materials other than solid stone for many applications. Steel cores with various covers – rubber, synthetic polymers, ceramics, or composites – are common. These covers can be engineered with specific hardness, surface energy, porosity, and temperature resistance properties tailored precisely to the demands of each position in the machine. They can also be lighter and potentially easier to resurface or replace than solid stone. So, why even discuss stone rollers? Their relevance endures partly in understanding the evolution of paper machine technology – how the industry learned what properties were needed in rollers. Furthermore, some older machines, still in operation around the world, continue to utilize stone rollers. There might also be niche applications where the unique combination of properties offered by a specific type of stone is still deemed advantageous, or where historical accuracy in restoration is important. Many experts agree that while materials have changed, the fundamental understanding of roller mechanics, developed partly through the use of stone, remains critical. It’s a testament to the foundational nature of these components in the complex ballet of paper production.

Comparison with Modern Roller Materials for Tissue Production

Comparing stone rollers to modern alternatives for tissue and toilet paper production highlights the trade-offs involved. Modern synthetic covers can offer greater flexibility in terms of hardness and surface texture, allowing for finer tuning of the pressing process to optimize bulk and softness. They can also incorporate specific chemical resistances or release properties that might be difficult to achieve with natural stone. Lighter weight cores can reduce bearing loads and energy consumption. However, modern covers can be susceptible to damage from cuts or delamination and may have a shorter lifespan requiring more frequent recovering compared to the potential longevity of a well-maintained stone roll surface. To be honest, the choice between traditional and modern materials depends heavily on the specific machine design, production speed, desired paper properties, and economic considerations including maintenance costs and downtime. While solid stone rollers might be less common in brand new, ultra-high-speed tissue machines, the legacy of their use and the understanding gained from their performance continue to inform the design and selection of modern roller technologies. It reinforces the idea that material science is continually seeking to improve upon established principles.

Conclusion: The Significance of Stone Rollers in Paper Production History and Machinery

In concluding our exploration of the stone roller for toilet paper and paper mill machinery, it’s clear that these components, particularly those made from materials like granite, have played a significant role in the development and operation of paper manufacturing technology. While modern materials and designs have become prevalent, understanding the historical application and the unique properties of stone rollers provides valuable insight into the fundamental requirements of roller performance in a paper machine. Their hardness, durability, specific surface characteristics, and thermal stability were leveraged for critical functions like dewatering and web guiding, contributing directly to the quality and consistency of the paper product, including delicate tissues like toilet paper. The challenges associated with their maintenance and the advent of engineered materials have led to shifts in technology, yet the principles of precise surface control, robust construction, and careful integration within the machine line remain paramount. Whether dealing with traditional stone or modern composite rolls, expertise in roller design, manufacturing, and maintenance is crucial for efficient and high-quality paper production. Our company understands the nuances of paper mill machinery components, including the principles derived from the use of various roller types throughout history and into modern applications, ensuring we can address the complex needs of today’s mills.

For more detailed information, please visit our official website: Stone Roller for Toilet Paper & Paper Mill Machinery