When we discuss the intricate mechanics behind the smooth, efficient production lines that churn out products we use daily, like toilet paper, it’s easy to overlook the critical, often unseen, components. Frankly speaking, the rubber roller stands out as a foundational element within paper industry equipment, serving not merely as a functional piece but often as a vital spare part whose condition directly impacts operational continuity and product quality. In the context of toilet paper manufacturing, where speed, precision, and surface quality are paramount, the performance of these rollers is under constant scrutiny. These rollers, designed with specific rubber compounds and surface treatments, perform a multitude of tasks from dewatering and pressing to guiding and winding the delicate paper web. Their role transcends simple movement; they are integral to the paper-making process itself, influencing moisture content, sheet formation, and the final texture and appearance of the paper. Understanding the significance of a high-quality rubber roller as a spare part for toilet paper and other paper industry equipment is the first step in appreciating the complexities of modern paper production. The demands placed upon these components are immense, involving high pressures, temperatures, and often corrosive chemical environments. Therefore, selecting the right roller, and having reliable spares on hand, isn’t just good practice—it’s absolutely essential for preventing costly downtime and ensuring consistent output. It’s worth noting that the specific requirements for rubber rollers can vary significantly between different types of paper machines and even different positions within the same machine, highlighting the need for specialized knowledge and sourcing. This detailed focus on the humble rubber roller is crucial because its failure can ripple through the entire production line, affecting everything downstream. Have you ever considered just how much pressure and speed a piece of paper experiences during its journey through a multi-story paper machine? It’s quite astonishing when you stop to think about it, and the rollers bear the brunt of that incredible workload. The longevity and performance of these rollers are a direct determinant of machine efficiency and, ultimately, profitability. Without reliable rubber rollers functioning correctly, the production of toilet paper and other paper products would be severely hindered, if not impossible. This makes the concept of a ‘spare part’ for these critical rollers less of a luxury and more of a strategic necessity for any paper mill operating at scale. The investment in quality spares pays dividends by minimizing unexpected stops and maintaining peak operational performance. Our exploration into this topic will delve deeper into the specifics, covering their functions, the challenges they face, and why a well-managed inventory of rubber roller spare parts is non-negotiable in the demanding world of paper manufacturing.

Understanding the Critical Role of Rubber Rollers in Paper Industry Equipment

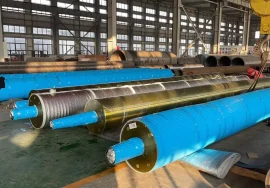

At the heart of virtually all modern paper industry equipment lies a series of rollers, and a significant portion of these are coated or made entirely of rubber. These rubber rollers are far from simple cylinders; they are engineered components designed to withstand extreme conditions and perform highly specific functions within the complex machinery of paper mills. Their primary roles include dewatering the paper web, pressing it to consolidate the fibers, guiding the sheet through various sections of the machine, and winding the finished product. In sections like the press section, rubber rollers work in tandem with other rollers, often metal or stone, under immense pressure—sometimes several hundred pounds per linear inch. This pressure squeezes water out of the paper sheet, drastically increasing its dry content and giving it structural integrity. The elasticity and surface properties of the rubber are critical here; they must deform uniformly under pressure, allowing for efficient water removal without damaging the delicate paper web. Interestingly enough, the rubber compound used for these rollers is carefully selected based on the specific requirements of its position in the machine, considering factors like temperature, chemical exposure from process water, abrasiveness of the pulp, and the desired grip or release properties. Different types of rubber, such as EPDM, Neoprene, or Polyurethane, each offer unique advantages in terms of chemical resistance, abrasion resistance, temperature tolerance, and mechanical strength. The surface finish or grooving on the rubber roller is also vital, influencing water drainage, sheet handling, and preventing issues like slippage or barring. In my experience, a roller that is perfectly suited for a couch roll position might be completely inadequate for a calender stack, highlighting the specialization involved. These rollers are not just passive components; they actively participate in shaping the paper, influencing its thickness, density, and surface smoothness. Their reliability is paramount because failure during operation can cause rips in the paper web, leading to significant production losses and requiring time-consuming shutdowns for repair or replacement. The ongoing development in rubber polymer technology continuously pushes the boundaries of what these rollers can endure, offering improved lifespan and performance under increasingly demanding operational parameters. This makes the rubber roller a linchpin in the entire paper-making process, supporting the high-speed, continuous operation that defines modern paper production facilities. Their design and maintenance are thus critical aspects of managing paper industry equipment effectively.

Functions of Rubber Rollers in Different Paper Machine Sections

Exploring the paper machine, you quickly realize rubber rollers serve varied purposes depending on their location. In the forming section, soft rubber rolls might be used for gentle handling or initial dewatering on vacuum rolls. As the paper web moves into the press section, the demands on rubber rollers escalate dramatically. Here, hard rubber or rubber-covered rolls are subjected to massive loads, working with granite or metal rolls to press water out. The specific hardness (measured in P&J or Shore D) and cover thickness are chosen based on the nip pressure and desired dewatering effect. Further downstream, in the dryer section, while many rolls are heated metal, certain guide rolls or felt rolls might still be rubber-covered to manage the web path at elevated temperatures. The sizing and coating sections often utilize rubber rollers, sometimes with specialized finishes or grooving, to apply chemicals or coatings uniformly to the paper surface. These applications require exceptional surface consistency and chemical resistance from the rubber. Finally, in the calender and reel sections, rubber rollers are crucial for smoothing the paper surface, controlling bulk, and winding the finished paper into large rolls. Calender rolls, in particular, operate under high temperature and pressure to impart gloss and smoothness, requiring highly specialized, heat-resistant rubber compounds. The precision of these finishing rolls is critical for achieving the desired paper properties. Frankly speaking, the sheer variety of functions means that “a rubber roller” isn’t a single item, but a diverse family of components, each tailored for a specific, demanding task within the paper machine. The success of each section relies heavily on the correct specification and flawless performance of its rubber rollers. This highlights why simply having ‘a spare’ isn’t enough; you need the right spare for the right position. The material science behind these covers is fascinating, balancing properties like hardness, elasticity, temperature resistance, and chemical compatibility to achieve optimal performance in a given machine section. Without this precise engineering, the efficiency and quality targets of modern paper production, especially for consumer goods like toilet paper which have specific softness and texture requirements, would be impossible to meet.

Specific Demands on Rubber Rollers in Toilet Paper Production

Toilet paper production presents a unique set of challenges and requirements for rubber rollers, distinct from those in producing heavier grades of paper or board. The paper web is typically very lightweight, soft, and absorbent, demanding gentle handling throughout the process. This necessitates rubber compounds and surface finishes that minimize the risk of web breaks, crushing, or marking the delicate sheet. In the through-air drying (TAD) process common for premium toilet paper, temperatures can be significantly higher than conventional drying, requiring rubber rollers (such as guide rolls or felt rolls) positioned in or near the hot air stream to possess excellent heat resistance. Furthermore, the pressing section in toilet paper machines is often designed for bulk and softness rather than maximum dewatering for strength, leading to specialized pressing configurations and softer rubber covers on some rolls compared to fine paper machines. Interestingly enough, Yankee dryers used in conventional tissue making involve pressing the wet web onto a large, heated cylinder, and the press roll applying the web to the Yankee often utilizes a specific type of rubber cover designed for this high-temperature nip and release characteristics. The surface of the rubber rollers in sections handling the dry or nearly dry sheet, such as calender rolls or reel spools, must be perfectly smooth and uniform to impart the desired finish and wind the roll tightly without crushing or creasing. Any imperfections on the roller surface will transfer to the paper, resulting in defects that affect quality and usability. To be honest, maintaining this pristine surface on rubber rollers under constant pressure and friction is a significant challenge. The chemicals used in the pulp and papermaking process, including additives for softness or wet strength, can also interact with the rubber, potentially causing swelling, hardening, or cracking over time. Therefore, the chemical compatibility of the rubber compound is a crucial selection criterion. Unlike producing stiff board where robust handling is possible, toilet paper production requires a delicate touch from start to finish, placing immense responsibility on the rubber rollers to guide and process the fragile web without damage, all while maintaining high production speeds. This specialized environment mandates equally specialized rubber roller solutions.

Why Quality Rubber Rollers are Essential Spare Parts

Considering the critical roles rubber rollers play and the harsh environments they operate in within paper industry equipment, it becomes abundantly clear why high-quality rubber rollers are not just components but essential spare parts. A paper machine is a highly integrated system, and the failure of a single critical roller can bring the entire line to a grinding halt. Downtime in a paper mill is incredibly expensive, measured not just in lost production but also in energy consumption during startups, potential damage to other machine components, and labor costs. Having a reliable spare rubber roller on hand, especially for critical positions like press rolls, couch rolls, or calender rolls, dramatically reduces the duration of unexpected shutdowns. Instead of waiting days or weeks for a new roller to be manufactured, shipped, and installed, a spare can be swapped in relatively quickly, often allowing production to resume within hours. But it’s not just about speed; the quality of the spare part is paramount. A poorly manufactured or improperly stored spare roller might not perform to the required specifications, leading to poor paper quality, reduced efficiency, or even accelerated wear and failure. Imagine the frustration and cost of installing a spare roller only to find it causes sheet breaks or leaves marks on the paper. This underscores the importance of sourcing spares from reputable suppliers who understand the demanding requirements of paper industry equipment and use high-quality rubber compounds and manufacturing processes. Furthermore, rubber rollers have a finite lifespan, influenced by factors like operational hours, pressure, temperature cycles, and chemical exposure. Proactive replacement based on condition monitoring or scheduled maintenance is a standard practice to avoid catastrophic failures. Having spare rollers available allows mills to implement these planned replacements efficiently, minimizing disruption. In my experience, mills that invest in a well-managed inventory of high-quality rubber roller spares generally experience fewer unexpected stops and maintain more consistent product quality compared to those who view spares as an afterthought. It’s a fundamental part of a robust maintenance strategy in the demanding paper industry. Without readily available, high-performance spare rubber rollers, paper mills would be operating on borrowed time, vulnerable to significant financial losses at any moment.

The Cost of Downtime vs. The Investment in Spare Rollers

Let’s talk frankly about the economics involved. The cost of downtime in a large paper mill can range from thousands to tens of thousands of dollars per hour, sometimes even more depending on the machine and grade being produced. A single unplanned shutdown due to a failed rubber roller, which could last for a day or more if a spare isn’t immediately available, can easily cost hundreds of thousands of dollars in lost production alone, not including repair costs. Contrast this with the cost of a high-quality spare rubber roller. While certainly an investment, the price of even a large, complex rubber roller is typically a fraction of the cost incurred by just a few hours of unscheduled downtime. This simple comparison highlights the clear economic rationale behind investing in a comprehensive spare parts inventory, particularly for critical components like rubber rollers. It’s not merely an expense; it’s a calculated insurance policy against substantial financial losses. Moreover, the potential damage to the machine itself if a roller fails catastrophically can be immense, requiring even more extensive and costly repairs. Many experts agree that a proactive maintenance strategy that includes having critical spare rollers on hand is one of the most effective ways to improve overall equipment effectiveness (OEE) and reduce operational risk in a paper mill. It allows maintenance teams to perform scheduled roller changes during planned outages, optimizing labor and minimizing disruption. This approach ensures that rollers are replaced before they fail, preventing both the direct cost of the failure and the indirect costs of emergency repairs and lost production. Ultimately, the investment in quality rubber roller spare parts is an investment in the reliability and profitability of the entire paper manufacturing operation. It demonstrates a commitment to operational excellence and risk mitigation, fundamental principles in any high-volume, continuous manufacturing environment.

Common Challenges and Wear Factors for Rubber Rollers in the Paper Industry

Rubber rollers in paper industry equipment face a relentless onslaught of challenges that contribute to their wear and eventual need for replacement as spare parts. The constant high pressure in press nips, for instance, causes the rubber compound to experience significant cyclic loading and deformation, which can lead to fatigue cracking or permanent deformation over time. This is particularly true for rolls with softer covers designed for higher bulk or gentle handling. High operating temperatures, especially near dryer sections or on calender rolls, can accelerate the aging process of the rubber, causing it to harden, lose elasticity, or crack. Conversely, very low temperatures can make some compounds brittle. Chemical exposure from process water, papermaking additives, or cleaning agents can degrade the rubber, altering its physical properties and potentially leading to swelling, surface tackiness, or chemical attack. The abrasive nature of paper pulp, containing mineral fillers and wood fibers, constantly wears down the rubber surface, changing its diameter and profile. This abrasion is exacerbated if there are hard particles or debris present. Mechanical damage is another frequent issue; nips can trap foreign objects, causing cuts, gouges, or indentations in the rubber cover. Even improper handling during installation or storage can lead to surface damage. Rollers used in high-speed applications generate internal heat due to hysteresis (energy dissipation within the rubber under cyclic stress), which, if not properly managed through cooling or compound selection, can lead to premature failure. These various wear factors mean that rubber rollers are consumables with a predictable, albeit variable, service life. Monitoring their condition—checking for changes in hardness, diameter, surface profile, cracking, or signs of chemical attack—is crucial for predicting when a spare will be needed. Ignoring these signs can lead to sudden, catastrophic failures. Understanding these wear mechanisms is vital for both selecting the appropriate rubber compound initially and for developing effective maintenance strategies that ensure optimal performance and timely replacement using reliable spare parts. The demanding operational environment means these rollers are constantly battling conditions that seek to shorten their useful life.

Selecting and Maintaining the Right Rubber Roller for Paper Industry Equipment (Spare Part)

Selecting the correct rubber roller for paper industry equipment, particularly when considering it as a crucial spare part, is a decision that requires careful consideration and technical expertise. It’s not a one-size-fits-all scenario. The specification must match the exact requirements of the roller’s position within the paper machine and the specific grade of paper being produced, such as toilet paper. Key factors include the required hardness and thickness of the rubber cover, the type of rubber compound (based on temperature, pressure, and chemical exposure), the desired surface finish or grooving pattern for water removal or sheet handling, and the required mechanical properties to withstand operating loads and speeds. Partnering with a knowledgeable supplier who understands the nuances of paper machine applications is invaluable. They can help specify the optimal rubber compound and roller construction for your specific needs, ensuring the spare roller will perform reliably when called upon. Once the roller is selected and acquired, proper maintenance and storage are equally critical to preserving its integrity as a spare part. Rubber can degrade over time, even when not in use, if exposed to adverse conditions. Storing spare rollers in a cool, dry environment away from direct sunlight, ozone sources (like electric motors), and corrosive chemicals is essential. They should ideally be stored on their journals or in specialized racks that support the entire length of the roller to prevent sagging or deformation. Regular inspection of stored spares—checking for surface cracks, changes in hardness, or signs of chemical attack—is also recommended. For rollers currently in operation, implementing a proactive maintenance program is key. This includes regular cleaning to remove buildup, monitoring surface temperature, checking for uniform wear, and periodic grinding or resurfacing to restore the correct profile and surface finish. Promptly addressing minor issues like small cuts or nicks can prevent them from propagating into larger problems that necessitate premature replacement. Effective selection, vigilant storage of spares, and proactive maintenance of operational rollers collectively contribute to maximizing roller lifespan, minimizing unexpected failures, and ensuring that when a rubber roller spare part is needed for your toilet paper or other paper industry equipment, it is in optimal condition and ready to perform its vital role. It’s a holistic approach that pays off in operational reliability and efficiency.

Importance of Supplier Expertise in Rubber Roller Selection

Choosing the right supplier for your rubber rollers, especially for critical spare parts, is a decision that cannot be taken lightly in the paper industry. A supplier with deep expertise in paper machine applications understands that the performance of a roller isn’t just about the rubber itself, but also the underlying core, the bonding layer between the rubber and the core, and the precise manufacturing process. They can analyze your specific operating conditions – the pressures, temperatures, speeds, chemical environment, and the type of paper being produced – and recommend the most suitable rubber compound and cover specifications. They know, for example, which compounds offer better abrasion resistance for certain pulp types or which ones are best suited for the high temperatures near a Yankee dryer. They can also advise on the correct surface finish or grooving pattern to optimize dewatering or sheet handling in specific machine sections for toilet paper production. A knowledgeable supplier can also provide valuable insights into proper roller handling, storage, and maintenance practices to maximize the lifespan of both your operational rollers and your spares. They might offer services like roller inspection, regrinding, or recovering worn cores. To be honest, relying solely on price when selecting a supplier for such critical components is often a false economy. The potential costs associated with a premature roller failure – from downtime to repair and quality issues – far outweigh any initial savings on a lower-quality spare part. Building a relationship with a supplier who acts as a technical partner, rather than just a vendor, is a strategic advantage. They can help you standardize roller specifications where possible, optimize your spare parts inventory, and provide rapid support when unexpected issues arise. This level of expertise and partnership is indispensable for maintaining the reliability and efficiency of your paper industry equipment.

The Impact of Advanced Materials on Rubber Roller Performance

The field of polymer science has advanced significantly over the years, and these advancements have had a profound impact on the performance and lifespan of rubber rollers used in toilet paper and other paper industry equipment. New synthetic rubber compounds and blends are continuously being developed that offer enhanced properties specifically tailored to the demanding conditions of paper mills. For example, some modern compounds provide significantly improved resistance to abrasion, allowing rollers to maintain their profile and surface finish for longer, even when processing abrasive pulps. Others are engineered for higher temperature resistance, enabling rollers to perform reliably in hotter sections of the machine without hardening or cracking prematurely. Chemical resistance has also seen significant improvements, with newer compounds able to withstand a wider range of process chemicals, reducing the risk of swelling or degradation that can compromise roller performance. Beyond the bulk properties of the rubber, advancements in manufacturing techniques, such as precision grinding and dynamic balancing, ensure that rollers meet extremely tight tolerances for concentricity and straightness. This precision is essential for maintaining uniform nip pressure, preventing vibrations at high speeds, and ensuring consistent paper quality, particularly important for the delicate web in toilet paper production. Surface treatments and grooving technologies have also evolved, allowing for better water removal in press sections, improved sheet release, and optimized air handling. Interestingly enough, composite materials are also being explored and sometimes integrated into roller design, offering potential benefits in terms of strength-to-weight ratio or thermal properties, though rubber covers remain dominant for their specific functional advantages. These material and manufacturing advancements mean that modern rubber rollers, when properly specified and maintained, can offer longer service intervals, improved operational efficiency, and higher reliability compared to those made with older technologies. This directly translates into reduced maintenance costs, less downtime, and more consistent product quality. For paper mills, staying informed about these material advancements and working with suppliers who utilize cutting-edge technologies is key to optimizing the performance of their paper industry equipment and getting the most value from their rubber roller spare parts inventory.

In conclusion, the rubber roller is a fundamentally important component in toilet paper and other paper industry equipment, playing diverse and demanding roles from dewatering and pressing to guiding and finishing. The harsh operating environment means these rollers are subject to significant wear and stress, highlighting their nature as essential spare parts. Investing in high-quality rubber rollers and maintaining a reliable inventory of spares is not merely a maintenance task but a strategic imperative for ensuring operational efficiency, minimizing costly downtime, and maintaining consistent product quality. The selection of the correct rubber compound, cover properties, and working with expert suppliers are critical steps in maximizing the performance and lifespan of these vital components. From the gentle handling required for delicate toilet paper webs to the immense pressures in press sections, the rubber roller’s performance is intrinsically linked to the overall success of the paper manufacturing process. We understand the critical nature of these components and the impact they have on your operations.

For more detailed information, please visit our official website: Rubber Roller