In the complex world of pulp and paper manufacturing, every component plays a vital role in ensuring quality and efficiency. Among the most critical are the various rolls that guide, press, and dry the paper web as it travels through the machine. Often, the performance of a paper mill hinges directly on the condition and suitability of its paper mill rolls. These seemingly simple cylinders are, in fact, sophisticated pieces of engineering, designed to withstand extreme conditions – high temperatures, pressures, varying moisture levels, and constant abrasion. Understanding their function, types, and proper care isn’t just important; it’s absolutely essential for minimizing downtime, maximizing output, and producing a consistent, high-quality product. Franky speaking, overlooking the details of your rolls can lead to significant operational headaches and costly inefficiencies down the line. Have you ever stopped to consider just how many different types of rolls interact to turn pulp into the finished paper product you use every day?

The Diverse World of Paper Machine Rolls

The journey of a paper web from wet slurry to dry sheet involves multiple stages, and each stage demands specific types of rolls. From the forming section where the initial sheet is created, through the press section where water is mechanically removed, to the drying section where heat does the rest, different rolls perform distinct functions. Consider the rolls in the forming section, like breast rolls, couch rolls, and guide rolls – they handle a very wet, fragile web and must ensure even distribution of fibers. Move to the press section, and you encounter press rolls, felt rolls, and suction rolls, built to exert immense pressure while efficiently dewatering the sheet without damaging its structure. Finally, in the drying section, yankee dryers, drying cylinders, and carrying rolls navigate high temperatures, managing heat transfer and web tension. This incredible diversity highlights why a generic “roll” simply won’t do; each position requires a roll engineered for specific stresses, temperatures, and interactions with the paper web and accompanying fabrics (like felts and wires). Selecting the right roll for the right job is paramount to achieving optimal machine performance and product characteristics. It’s worth noting that wear and tear are constant challenges across all these types, necessitating robust materials and precision engineering.

Understanding Key Roll Types and Functions

Let’s delve a little deeper into some of these crucial components. Take, for instance, press rolls. These are arguably some of the most heavily stressed rolls in the entire paper machine. Their primary function is to squeeze water out of the paper web and felt, improving dryness before the energy-intensive drying phase. They often operate under pressures exceeding several hundred pounds per linear inch (PLI) and must maintain a perfectly uniform nip profile across the entire width of the machine to ensure even dewatering and caliper control. Materials like granite, rubber, synthetic polymers, and even specialized composite covers are used, each offering different properties related to hardness, elasticity, wear resistance, and affinity for water. Then there are the numerous guide rolls and spreader rolls found throughout the machine. While they don’t apply heavy pressure or heat, they are critical for controlling web tension, alignment, and preventing wrinkles or breaks. Their surfaces must be smooth and resistant to buildup. The massive yankee dryers, central to many tissue machines, are perhaps the most iconic rolls, heating the paper from one side while a creping blade removes it, requiring specific metal alloys and highly polished surfaces. Each roll type, from the smallest idler to the largest dryer, presents its own set of engineering challenges and operational considerations.

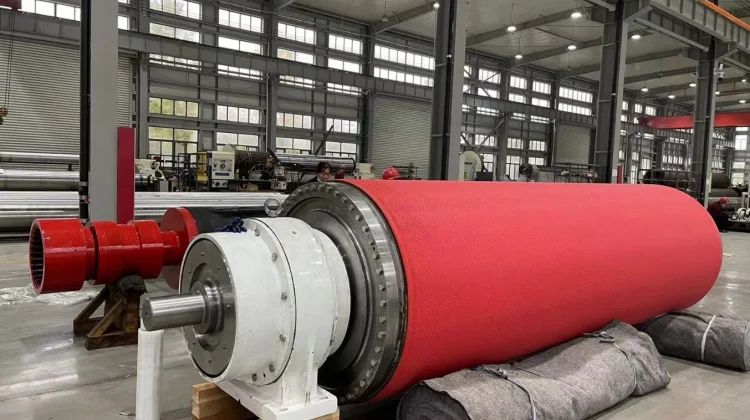

Materials and Construction of Modern Paper Mill Rolls

The performance and lifespan of a paper mill roll are fundamentally determined by its materials and construction. The core of the roll is typically a robust steel or cast iron shell, designed to withstand the immense mechanical loads and thermal stresses encountered during operation. However, it’s the surface material that often dictates the roll’s function and resistance to wear, corrosion, and buildup. For press rolls, covers can range from traditional granite (known for its hydrophilic properties aiding dewatering) to advanced synthetic rubber and polyurethane compounds offering specific hardness ranges, chemical resistance, and dynamic properties. These covers are often applied in multiple layers through complex processes like casting, winding, or spraying. In high-temperature sections like drying, rolls are usually steel or cast iron cylinders, precisely machined and sometimes coated with chrome or other materials to enhance heat transfer and release properties. Felt rolls and wire rolls might use rubber, ceramic, or composite covers to provide necessary grip and wear resistance while interacting with the machine clothing. Interestingly enough, the internal construction, including journals, bearings, and internal cooling or heating passages (in some cases), is just as critical as the outer shell and cover, ensuring smooth rotation, proper load distribution, and temperature control. The engineering behind selecting and combining these materials for optimal performance in harsh conditions is truly remarkable.

Ensuring Longevity: Maintenance and Inspection

Maintaining paper machine rolls isn’t just about reacting when something goes wrong; it’s about proactive, predictive care. Given the high costs associated with roll replacement and the downtime it incurs, a comprehensive maintenance program is crucial. This includes regular inspections for signs of wear, damage, or cover deterioration. Non-destructive testing methods, such as ultrasonic testing, eddy current testing, and infrared thermography, are invaluable tools for assessing internal integrity, cover thickness, and temperature profiles without removing the roll from the machine or causing damage. Grinding and crowning are standard maintenance procedures to restore the roll’s precise cylindrical or desired profile, compensating for wear and ensuring uniform nip pressure or contact across the web width. Balancing is also essential, especially for high-speed machines, to prevent vibration that can damage bearings, impact paper quality, and even pose safety risks. Bearing lubrication and condition monitoring are equally critical; a bearing failure can lead to catastrophic roll damage and extensive downtime. Implementing a rigorous schedule for these tasks, often guided by manufacturer recommendations and operational experience, is key to maximizing roll life and machine reliability. It’s certainly a significant investment of time and resources, but one that pays dividends in reduced unexpected stops.

Addressing Common Challenges with Paper Mill Rolls

Despite meticulous design and maintenance, paper mill rolls face numerous challenges in the demanding production environment. One common issue is roll cover wear and damage, caused by abrasive fibers, chemicals, or even foreign objects entering the machine. This can lead to uneven roll profiles, poor dewatering, increased web breaks, and reduced paper quality. Another significant challenge is buildup of pitch, stickies, and other contaminants on roll surfaces, affecting sheet release, causing picking, and disrupting web runability. Temperature control is also critical; uneven temperatures can lead to expansion differences, affecting roll profile and potentially causing thermal cracks, particularly in dryer cylinders. Vibration, often stemming from imbalance, bearing issues, or misalignment, can severely impact roll performance and machine stability. Furthermore, corrosion can be a concern, especially in areas exposed to process water or chemicals. Addressing these issues requires a multi-faceted approach: selecting the most appropriate cover materials resistant to specific contaminants or wear mechanisms, implementing effective cleaning systems (like high-pressure showers), ensuring precise temperature management, rigorous balancing, and condition monitoring programs. Sometimes, optimizing process chemistry can also help mitigate buildup issues. Tackling these challenges head-on is vital for maintaining consistent production quality and volume.

The Impact of Roll Performance on Paper Quality

It might not be immediately obvious, but the condition and performance of every single paper mill roll directly influence the quality of the final paper product. An improperly crowned press roll, for instance, will result in uneven dewatering across the sheet width, leading to variations in moisture content, caliper (thickness), and strength. A worn or damaged guide roll can cause wrinkles, creases, or even web breaks, requiring the affected paper section to be discarded. Buildup on dryer cylinders can lead to picking, leaving surface defects on the paper. Imbalance in high-speed rolls causes vibration, which can negatively impact formation, smoothness, and even strength properties. Even subtle variations in roll surface finish or temperature can affect how the paper interacts with the roll, influencing everything from gloss and printability to porosity and absorption. To be honest, achieving consistent, high paper quality is impossible without ensuring that all rolls are operating within their specified parameters, with accurate profiles, smooth surfaces, and proper alignment. This interdependency highlights why investing in quality rolls and their ongoing care is not just an operational concern but a direct investment in product excellence and customer satisfaction. This is where expertise in manufacturing and servicing paper machine rolls becomes invaluable.

Selecting and Specifying the Right Paper Mill Roll

Choosing the correct paper mill roll for a specific position and application is a complex decision that requires careful consideration of numerous factors. It’s not simply about size; the intended function (pressing, guiding, drying, etc.), the type of paper being produced, machine speed, operating temperatures and pressures, required cover properties (hardness, chemical resistance, wear resistance, release properties), and budget all play significant roles. Manufacturers offer a wide range of standard and custom options tailored to different machine types and process conditions. Working closely with experienced suppliers is crucial during the selection process. They can provide expertise on material suitability, cover options, and design considerations based on their extensive knowledge and testing. For unique applications or persistent problems, **custom paper mill rolls** might be necessary, designed from the ground up to address specific operational challenges that standard rolls cannot. This could involve unique core designs, specialized cover compounds, or innovative internal features. Taking the time to thoroughly evaluate the requirements and consult with experts ensures that the chosen roll will provide the necessary performance, durability, and return on investment over its lifespan. It’s a decision that shouldn’t be rushed.

Why Expertise Matters in Roll Manufacturing and Service

The precision required in manufacturing, covering, grinding, and balancing paper mill rolls is immense. Tolerances are often measured in microns, and achieving the necessary surface finish and profile accuracy demands specialized equipment and highly skilled technicians. This is why relying on experienced manufacturers and service providers is paramount. They possess the deep understanding of materials science, mechanical engineering, and paper machine dynamics needed to produce rolls that perform reliably under extreme conditions. Their expertise extends beyond initial manufacturing to critical services like regrinding, recovering, balancing, and inspection, which are essential for maintaining roll performance throughout its operational life. Furthermore, experienced providers can offer valuable insights into optimizing roll performance for specific machine conditions or helping troubleshoot persistent issues related to roll wear, vibration, or buildup. They can recommend the most suitable covers or coatings, advise on optimal grinding intervals, and provide advanced diagnostic services. Leveraging this expertise can significantly extend roll life, reduce maintenance costs, improve machine efficiency, and ultimately enhance paper quality. Partnering with specialists ensures you’re not just buying a piece of equipment, but gaining a wealth of knowledge and support crucial for success in the demanding paper industry.

Looking Ahead: Innovations in Paper Mill Roll Technology

The technology behind paper mill rolls isn’t standing still. Continuous innovation is driving improvements in materials, design, and manufacturing processes. Researchers and manufacturers are developing new composite materials and advanced polymers for roll covers that offer superior wear resistance, release properties, and chemical resistance, potentially reducing the need for frequent grinding or replacement. Improvements in internal cooling and heating systems are leading to more precise temperature control, enhancing drying efficiency and reducing thermal stress on rolls. The development of smart rolls, equipped with integrated sensors to monitor temperature, vibration, nip pressure, and even internal stress in real-time, is poised to revolutionize roll maintenance and machine optimization, enabling truly predictive maintenance and fine-tuning of operational parameters. Additive manufacturing (3D printing) is also being explored for creating complex internal structures or repair parts. These advancements promise to further increase machine speeds, improve paper quality, extend roll service intervals, and enhance overall operational efficiency and sustainability. Staying abreast of these innovations is key for paper mills looking to remain competitive in a global market.

Ultimately, the paper mill roll is far more than just a cylindrical component; it is a precision-engineered tool critical to the heart of paper production. Its design, material composition, and condition directly impact everything from machine efficiency and energy consumption to the quality and consistency of the final product. Investing in high-quality rolls, implementing a robust maintenance program, and leveraging the expertise of experienced manufacturers and service providers are not optional; they are fundamental requirements for success in the modern paper industry. Understanding the nuances of different roll types, the stresses they endure, and the technologies available to maintain and improve their performance is key to unlocking the full potential of your paper machine. If you’re facing challenges with roll wear, performance, or looking to optimize your machine’s efficiency, exploring advanced roll solutions and expert services can provide significant benefits. What steps could your mill take today to improve the health and performance of its critical rolls?

For more detailed information, please visit our official website: paper mill roll