In the fascinating world of paper production, few components are as critical yet perhaps as understated as the various paper mill rolls. These aren’t just simple cylinders; they are highly engineered elements that play a pivotal role at every stage of the paper machine, from forming the initial sheet to pressing out water and imparting the final finish. Their performance directly impacts paper quality, machine efficiency, and ultimately, profitability. Understanding the complexities of these rolls – their design, function, materials, and upkeep – is absolutely essential for anyone involved in this demanding industry. Frankly speaking, without optimized rolls, achieving consistent, high-quality paper output at competitive speeds is simply not possible. They endure immense pressure, heat, and chemical exposure, making their engineering and maintenance paramount to operational success. Have you ever truly considered the silent, relentless work these rolls perform minute after minute, day after day?

The Diverse World of Paper Machine Rolls: Types and Functions

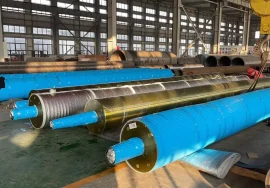

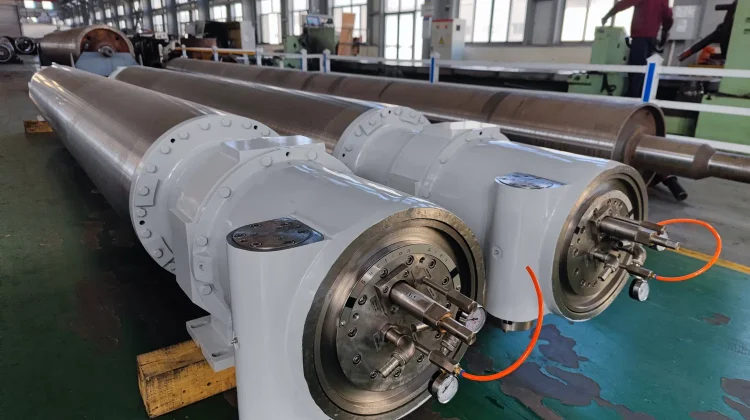

The term “paper mill rolls” is a broad category encompassing a wide array of specialized rolls, each designed for a specific task within the paper machine. In the forming section, you have forming rolls and couch rolls, responsible for dewatering the pulp slurry and consolidating the nascent paper web. Moving into the press section, press rolls, blind-drilled rolls, grooved rolls, and suction rolls work together under tremendous pressure to squeeze out more water, increasing the web’s dry content and strength. The dryer section utilizes dryer cylinders and felt rolls to guide the paper through heated sections, evaporating the remaining moisture. Finally, the calendar section employs calender rolls, including chilled iron rolls or soft rolls, to smooth and finish the paper surface, controlling caliper, gloss, and other properties. Each type requires specific materials, coatings, and surface finishes tailored to its operating environment and function. Getting the right roll for the job, and ensuring it performs optimally, is a constant challenge and a key determinant of product quality.

Specialized Roles in the Press Section

Focusing specifically on the press section, the different paper mill rolls here are engineering marvels in their own right. Press rolls, often covered with rubber, polyurethane, or composite materials, apply mechanical pressure. Suction rolls feature a perforated shell through which vacuum is applied, assisting in water removal and preventing crushing. Grooved rolls and blind-drilled rolls provide channels for water to escape the nip under pressure, improving dewatering efficiency and reducing rewetting. The material science behind the roll covers is crucial; it must withstand high loads, temperature variations, and chemical exposure while maintaining specific hardness and surface properties. The deflection profile of these rolls is also precisely controlled, often using crown rolls or variable crown rolls, to ensure even pressure distribution across the full width of the paper web. Without this sophisticated approach to roll design and application in the press section, achieving the necessary dry content before the energy-intensive drying phase would be inefficient and cost-prohibitive.

Materials and Coatings: Engineered for Extremes

The harsh operating conditions within a paper machine necessitate the use of advanced materials and specialized coatings for paper mill rolls. The base shells are typically made from steel or cast iron, selected for their strength and rigidity. However, it’s the surface that truly faces the brunt of the process. Rubber covers have traditionally been used, offering elasticity and good gripping properties, but they are susceptible to wear and chemical attack. Polyurethane covers provide enhanced abrasion and chemical resistance and can be engineered for specific hardness profiles. Composite covers, often reinforced with carbon fiber, offer superior stiffness-to-weight ratios and dimensional stability, especially important for rolls in high-speed machines. Metallic coatings, like chromium or ceramics, are applied to calendar rolls and certain press rolls to provide extreme hardness, wear resistance, and specific surface finishes for calendering. The selection of the right material and coating combination is a complex decision based on the roll’s position in the machine, the paper grade being produced, and the specific operational demands. Investing in the correct, high-performance materials for paper mill rolls is critical for extending their lifespan and maintaining consistent product quality.

The Importance of Surface Finish and Properties

Beyond the base material and cover, the surface finish and properties of paper mill rolls are paramount. The surface texture, or roughness, influences dewatering efficiency in press rolls, sheet release properties, and the final finish of the paper in calender rolls. Precisely controlled surface roughness, often measured in Ra (arithmetic average roughness) or Rz (average maximum height of the profile), is achieved through grinding, polishing, or specialized texturing techniques. The hardness of the roll cover or surface is also a critical parameter, affecting nip pressure distribution, wear rate, and mark resistance. For instance, softer covers in the press section can conform better to the web and felts, improving dewatering, while hard calender rolls are needed to impart gloss and density. Maintaining the correct surface finish and hardness throughout the roll’s operational life is a key aspect of effective roll maintenance. Deviations can lead to uneven moisture profiles, caliper variations, and surface defects in the paper.

Maintenance of Paper Mill Rolls: A Proactive Approach

Effective maintenance of paper mill rolls is not merely reactive; it’s a proactive, ongoing process essential for preventing costly breakdowns and ensuring consistent paper quality. A comprehensive roll maintenance program involves regular inspection, cleaning, grinding, and cover replacement. Rolls are subject to wear, crowning changes, damage from foreign objects, and cover degradation over time. Regular grinding is necessary to restore the ideal crown profile and surface finish, compensating for uneven wear. Cleaning protocols are vital to prevent pitch, fiber, and chemical buildup, which can affect dewatering, cause barring, or damage the roll surface. Predictive maintenance techniques, such as vibration analysis, thermal imaging, and non-destructive testing (NDT), are increasingly used to monitor roll health and detect potential issues before they lead to failure. Investing in a robust maintenance schedule and the necessary equipment for servicing paper mill rolls pays dividends by minimizing downtime and extending the operational life of these valuable assets. Without meticulous care, even the best-engineered rolls will underperform.

Developing a Robust Roll Grinding Strategy

Roll grinding is a cornerstone of effective paper mill rolls maintenance. This process restores the precise cylindrical shape and engineered crown profile of the roll, compensating for wear that naturally occurs during operation. Uneven wear or an incorrect crown leads to uneven pressure distribution across the paper web, resulting in variations in moisture profile, caliper, and finish. A well-defined roll grinding strategy considers factors like the roll type, material, operating conditions, and the specific paper grade being produced. Regular inspection for wear patterns, surface damage, and out-of-roundness helps determine the optimal grinding frequency. Precision grinding equipment is essential to achieve the required tolerances and surface finish. The goal is to remove the minimum amount of material necessary to restore the roll’s geometry and surface properties, maximizing the number of grinds possible before the roll needs recovering or replacement. Developing and adhering to a strategic roll grinding program is critical for optimizing paper roll performance and controlling maintenance costs.

Optimizing Paper Roll Performance Through Technology

The pursuit of optimizing paper roll performance is continually driven by technological advancements. Condition monitoring systems, incorporating sensors for vibration, temperature, and acoustic emissions, provide real-time data on roll health, allowing for early detection of potential problems. Online roll profile measurement systems can assess wear and crown changes without stopping the machine, enabling data-driven decisions about when to grind. Advanced control systems can dynamically adjust nip pressure and profile based on real-time feedback, ensuring consistent pressure distribution even as conditions change. Furthermore, innovations in roll cover materials, such as nanocomposites or specialized polymers, continue to push the boundaries of wear resistance, dewatering efficiency, and release properties. Variable crown rolls, using hydraulic systems to adjust the crown profile on the fly, offer unprecedented flexibility in adapting to different paper grades and operating speeds. Leveraging these technologies is key to squeezing maximum efficiency and quality out of paper mill rolls in modern paper production environments. It’s exciting to see how technology continues to enhance the capabilities of these essential machine elements.

Leveraging Data for Predictive Maintenance

In today’s data-rich industrial landscape, leveraging data analytics is revolutionizing the maintenance of paper mill rolls. Instead of relying solely on scheduled maintenance or reacting to failures, paper mills are increasingly adopting predictive maintenance strategies. By collecting and analyzing data from sensors – including vibration, temperature, load, and even process parameters like moisture profiles – algorithms can predict when a roll is likely to require maintenance or fail. This allows maintenance activities, such as grinding or cover replacement, to be scheduled optimally, minimizing unplanned downtime and maximizing roll lifespan. Analyzing historical data can also help identify root causes of premature wear or failure, leading to improvements in operational practices or roll design. This data-driven approach not only reduces maintenance costs but also contributes to more consistent and higher-quality production by ensuring rolls are always operating within their optimal parameters. Frankly speaking, if you’re not using data to inform your roll maintenance, you’re likely leaving performance and cost savings on the table.

Challenges and Solutions in Roll Management

Managing paper mill rolls comes with its unique set of challenges. These include uneven wear patterns due to variations in pulp consistency or sheet moisture, damage from foreign objects entering the nip, chemical degradation of covers, and the sheer logistical challenge of managing inventory, grinding schedules, and roll changes for a large paper machine. Finding skilled technicians capable of precise grinding and roll maintenance is also a persistent challenge. Solutions involve implementing rigorous operational procedures to minimize foreign objects, optimizing chemical additives to reduce cover degradation, and establishing a comprehensive inventory management system for spare and serviced rolls. Investing in training for maintenance personnel and leveraging partnerships with experienced roll service providers can significantly mitigate these challenges. Additionally, exploring newer, more resilient roll cover materials can help extend service intervals and reduce maintenance frequency. Effectively addressing these challenges is vital for maintaining smooth, efficient, and cost-effective paper production.

Optimizing the performance of paper mill rolls is an ongoing journey that combines selecting the right equipment, implementing diligent maintenance practices, and embracing technological advancements. The reliability and efficiency of these components are fundamental to the success of any paper manufacturing operation. Ensuring rolls are properly specified, expertly maintained, and replaced proactively when needed directly translates into improved paper quality, increased machine uptime, and lower operating costs. It’s clear that a strategic focus on paper mill rolls is an investment that yields significant returns in the long run. What steps are you taking today to ensure your rolls are performing at their absolute best? Are you leveraging the latest in monitoring and maintenance technology?

For more detailed information, please visit our official website: paper mill rolls